Iimveliso

-

Intengiso ethe ngqo yefektri yaseTshayina yentsimbi ekumgangatho ophezulu ene-U-groove eyenziwe nge-U

Intsimbi enobume buka-U luhlobo lwentsimbi enobume buka-U enamandla aphezulu kunye nokumelana okuhle nokugoba, efanelekileyo ukuthwala imithwalo enzima. Ubunzima bayo obulula, kulula ukuyithutha nokuyifakela, kunye nokudityaniswa kakuhle, efanelekileyo ukuqhagamshelwa nezinye izinto. Ukongeza, intsimbi enobume buka-U idla ngokuba yi-galvanized kwaye inokumelana okukhulu nokugqwala. Isetyenziswa kakhulu ekwakheni, kwiibhulorho, kwimveliso yoomatshini nakwamanye amasimi, sisixhobo esibalulekileyo sokwakha.

-

Ixabiso likaloliwe elisemgangathweni ophezulu elishushu nelichanekileyo

Iireli zentsimbi ziyinxalenye ebalulekileyo ekuthuthweni koololiwe. Zinamandla aphezulu kwaye ziyamelana nokuguguleka kwaye ziyakwazi ukumelana noxinzelelo olunzima kunye neempembelelo ezixhaphakileyo zoololiwe. Zihlala zenziwe ngentsimbi yekhabhoni ephathwa ngobushushu ukuze yonyuse ubulukhuni kunye nokuqina. Uyilo lweereli luqinisekisa uzinzo oluhle kunye nokhuseleko, kwaye lunokunciphisa ngempumelelo ukungcangcazela kunye nengxolo xa oololiwe besebenza. Ukongeza, ukumelana nemozulu kweereli kubenza bakwazi ukugcina ukusebenza kakuhle kwiimeko ezahlukeneyo zemozulu kwaye zifanelekile ukusetyenziswa ixesha elide. Lilonke, iireli zisisiseko esibalulekileyo sokuqinisekisa ukusebenza ngokukhuselekileyo nangokufanelekileyo koololiwe.

-

Ityhubhu Eshushu Etyibiliziweyo Egqunywe Ngesinyithi I-Mobile Gi Scaffolding Iron Round Steel Pipe

Iipayipi zescaffolding ziipayipi zentsimbi ezingenanto ezisetyenziselwa ukwakhiwa ukuze zinike inkxaso yesakhiwo kunye nokufikelela kubasebenzi. Zihlala zisetyenziselwa ukwenza izakhiwo zexeshana zokugcinwa, ukwakhiwa, kunye nomsebenzi wokulungisa. Ezi pipes ziza ngobukhulu obahlukeneyo kwaye zenzelwe ukumelana nobunzima babasebenzi kunye nezixhobo zokwakha.

-

Ixabiso lentsimbi yesinyithi se-C channel slot eyenziwe ngokwezifiso

Intsimbi ye-C-channel luhlobo lwentsimbi yokwakha enesimo se-C enamandla aphezulu kunye nokuqina, efanelekileyo ukuthwala imithwalo emikhulu. Iimpawu zayo ziquka: ubunzima obuphantsi kunye namandla aphezulu, kulula ukuyithutha nokuyifakela; Ukusebenza kakuhle koqhagamshelo, kulula ukuyishibiliza kunye nokudibanisa ibholiti; Ukumelana nokugqwala, ngokuqhelekileyo emva konyango lokulwa nomhlwa; Ukusebenza kakuhle, kunokunqunyulwa nokugotywa. Intsimbi ye-C-channel isetyenziswa kakhulu ekwakheni, ebhulohweni, kwizixhobo zoomatshini nakwiishelufu zokugcina, kwaye inomsebenzi ogqwesileyo wolwakhiwo kunye nokuziqhelanisa.

-

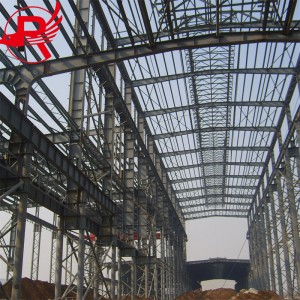

Indawo yoLwakhiwo lweNsimbi enesakhiwo seNsimbi Isakhiwo sokuHlala siyasebenza

Isakhiwo sentsimbisisakhiwo esenziwe ngezinto zentsimbi kwaye sesinye sezona ntlobo ziphambili zesakhiwo. Esi sakhiwo senziwe kakhulu ngemiqadi yentsimbi, iikholamu zentsimbi, ii-trusses zentsimbi kunye nezinye izinto ezenziwe ngentsimbi yecandelo kunye neepleyiti zentsimbi, kwaye samkela i-silanization, i-phosphating ye-manganese ecocekileyo, ukuhlamba kunye nokomisa, i-galvanizing kunye nezinye iinkqubo zokuthintela umhlwa.

*Ngokuxhomekeke kwisicelo sakho, singayila inkqubo yesakhelo sesinyithi engabizi kakhulu nehlala ixesha elide ukukunceda wenze ixabiso eliphezulu kwiprojekthi yakho.

-

Indawo yokugcina izinto esele ilungisiwe Isakhiwo sentsimbi Indawo yokusebenzela Isakhiwo sentsimbi yezimboni Indawo yokugcina izinto esele ilungisiwe

isakhiwo sentsimbi yemizi-mvelisosisakhiwo esenziwe ngezinto zentsimbi kwaye sesinye sezona ntlobo ziphambili zesakhiwo. Esi sakhiwo senziwe kakhulu ngemiqadi yentsimbi, iikholamu zentsimbi, ii-trusses zentsimbi kunye nezinye izinto ezenziwe ngentsimbi yecandelo kunye neepleyiti zentsimbi, kwaye samkela i-silanization, i-phosphating ye-manganese ecocekileyo, ukuhlamba kunye nokomisa, i-galvanizing kunye nezinye iinkqubo zokuthintela umhlwa.

*Ngokuxhomekeke kwisicelo sakho, singayila inkqubo yesakhelo sesinyithi engabizi kakhulu nehlala ixesha elide ukukunceda wenze ixabiso eliphezulu kwiprojekthi yakho.

-

Ixabiso leepali zesinyithi ezishushu zaseTshayina ezisemgangathweni ophezulu nezinamandla aphezulu

Iingqumba zesinyithi zentsimbi luhlobo lwesakhiwo esikhuselayo esisetyenziswa kubunjineli bokwakha kunye nokwakhiwa kweziseko, ngokuqhelekileyo zenziwe ngentsimbi, enamandla aphezulu kunye nokumelana nokugqwala. Zenza imiqobo eqhubekayo ngokuqhuba okanye ukufaka emhlabeni, kwaye zisetyenziswa kakhulu kubunjineli be-hydraulic, ukwakhiwa kwezibuko kunye nokuxhasa isiseko. Iingqumba zesinyithi zentsimbi zinokumelana ngempumelelo nokukhukuliseka komhlaba kwaye zibonelele ngendawo yokwakha ezinzileyo, kwaye zihlala zisetyenziselwa ukumba imingxuma enzulu yesiseko okanye ukuthintela amanzi ukuba angakhukulisi kwindawo yokwakha.

-

Isaphulelo sexabiso lesitimela esithe ngqo somzi-mveliso waseTshayina esisemgangathweni ophezulu

Iimpawu zeereli ziquka kakhulu amandla aphezulu, ukumelana nokuguguleka kunye nozinzo oluhle. Zihlala zenziwe ngentsimbi esemgangathweni ophezulu kwaye ziyakwazi ukumelana noxinzelelo olunzima kunye nokusebenza ngesantya esiphezulu kwesitimela, ukuqinisekisa ukhuseleko. Ukongeza, iireli zinokumelana okuhle nokugqwala kwaye zinokugcina ukusebenza kwiimeko ezahlukeneyo zemozulu. Uyilo lwazo lukwaqwalasela nemiphumo yokwanda kunye nokucutheka kobushushu, ukuqinisekisa ukuba utshintsho kumaqondo obushushu aluyi kubangela ukuguquka okanye umonakalo. Okokugqibela, iireli zibekwe ngokuchanekileyo okuphezulu, zibonelela ngamava okuqhuba athambileyo kwaye zinciphisa ukungcangcazela kunye nengxolo yesitimela.

-

Ixabiso elifanelekileyo kunye nomthengisi osemgangathweni olungileyo waseTshayina oneentsimbi ezimile okwe-H

Iimpawu zentsimbi enobume be-H ziquka amandla aphezulu, uzinzo oluhle kunye nokumelana okuhle kokugoba. Inxalenye yayo imile okwe-"H", enokusasaza amandla ngempumelelo kwaye ifanelekile kwizakhiwo ezithwala imithwalo emikhulu. Inkqubo yokuvelisa intsimbi enobume be-H yenza ukuba ibe nokudityaniswa okungcono kunye nokucutshungulwa ngcono, kwaye yenza kube lula ukwakhiwa kwindawo. Ukongeza, intsimbi enobume be-H ilula ngobunzima kwaye inamandla aphezulu, nto leyo enokunciphisa ubunzima besakhiwo kwaye iphucule uqoqosho kunye nokhuseleko lwesakhiwo. Isetyenziswa kakhulu kwiindawo ezifana nokwakha, iibhulorho kunye nokuveliswa koomatshini, kwaye ibe yinto efunekayo kubunjineli banamhlanje.

-

Intsimbi ye-Angle ASTM Intsimbi ye-Angle ekhabhoni ephantsi Intsimbi ye-Angle egayiweyo Intsimbi ye-Angle ...

I-Angle steel luhlobo lwentsimbi esetyenziswa kakhulu kulwakhiwo nobunjineli boomatshini, enamandla aphezulu kunye nokumelana nokuguquguquka, enokuxhasa ngempumelelo izakhiwo kwaye igcine uzinzo. Uyilo lwayo lwecandelo olumile njengo-L lwenza ukuba imelane nokugoba nokujika xa ixinezelekile, okwenza ukuba ifaneleke kwiindlela ezahlukeneyo zokusetyenziswa ezifana neefreyimu, izibiyeli kunye nezihlanganisi. I-Angle steel kulula ukuyicubungula, ukuyishibiliza kunye nokuyifakela, iyaziqhelanisa neemfuno ezahlukeneyo zobunjineli, kwaye inokuphucula ukumelana nokugqwala kwaye yandise ubomi benkonzo ngonyango lomphezulu.

-

Ulwakhiwo olulungisiweyo Izinto zeMetal zoShishino I-Hangar Shed Indawo yokugcina impahla Indawo yokusebenzela Isakhiwo seNsimbi Isakhiwo

izakhiwo zentsimbi, iintsimbi ezinamandla aphezulu kufuneka zifundwe ukuze zonyuse kakhulu amandla azo okufumana amanqaku. Ukongeza, iintlobo ezintsha zeentsimbi, ezifana nentsimbi enomfanekiso we-H (ekwaziwa ngokuba yintsimbi ebanzi) kunye nentsimbi enomfanekiso we-T, kunye neepleyiti zentsimbi ezineprofayili, ziyasongwa ukuze zilungele izakhiwo ezinkulu kunye nesidingo sezakhiwo eziphakamileyo kakhulu.Ukongeza, kukho inkqubo yesakhiwo sentsimbi yebhulorho engatshisi ubushushu. Isakhiwo ngokwaso asisebenzisi umbane kakuhle. Le teknoloji isebenzisa izihlanganisi ezikhethekileyo ezikrelekrele ukusombulula ingxaki yeebhulorho ezibandayo nezishushu kwisakhiwo. Isakhiwo esincinci se-truss sivumela iintambo kunye nemibhobho yamanzi ukuba idlule eludongeni ukuze kwakhiwe. Ukuhombisa kulula.

-

Isakhelo seNdawo yeSinyithi esakhiwe kwangaphambili sokugcina impahla Ulwakhiwo lweSakhiwo seNsimbi

Ukuziqhelanisa kubonisile ukuba okukhona amandla emakhulu, kokukhona ukuguguleka kwelungu lesinyithi kukhulu. Nangona kunjalo, xa amandla emakhulu kakhulu, amalungu esinyithi aya kuqhekeka okanye ukuguguleka okukhulu kweplastiki, okuya kuchaphazela umsebenzi oqhelekileyo wesakhiwo sobunjineli.Isakhiwo sentsimbisisakhiwo esenziwe ngezinto zentsimbi kwaye sesinye sezona ntlobo ziphambili zesakhiwo. Esi sakhiwo senziwe kakhulu ngemiqadi yentsimbi, iikholamu zentsimbi, ii-trusses zentsimbi kunye nezinye izinto ezenziwe ngentsimbi yecandelo kunye neepleyiti zentsimbi, kwaye samkela i-silanization, i-phosphating ye-manganese ecocekileyo, ukuhlamba kunye nokomisa, i-galvanizing kunye nezinye iinkqubo zokuthintela umhlwa.

*Ngokuxhomekeke kwisicelo sakho, singayila inkqubo yesakhelo sesinyithi engabizi kakhulu nehlala ixesha elide ukukunceda wenze ixabiso eliphezulu kwiprojekthi yakho.