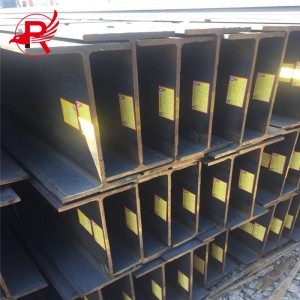

Umgangatho ophezulu h16 x 101 150x150x7x10 Q235 Q345b I-Hot Rolled IPE HEA HEB EN Intsimbi Emile okwe-H

INKQUBO YOKUVELISA IMVELISO

Ezi mpawu zibonisa iintlobo ezahlukeneyoImiqadi ye-IPE esekwengobukhulu kunye neempawu zazo:

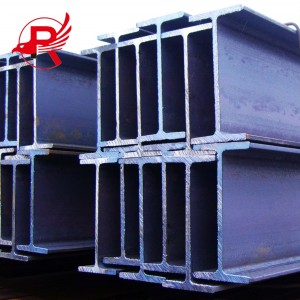

- I-HEAAmacandelo entsimbi (IPN): La ngamasebe entsimbi anomfanekiso we-I aneeflange ezibanzi kunye neeweb ezityebileyo, ezifanelekileyo kwizicelo zesakhiwo ezifuna amandla aphezulu okuthwala umthwalo.

- I-HEBAmacandelo entsimbi (IPB): La ngamaplanga entsimbi anomfanekiso we-I anobubanzi kunye nobukhulu obuphakathi beflange, asetyenziswa rhoqo kwizakhiwo ezahlukeneyo.

- Amacandelo entsimbi yohlobo lwe-HEM: La ngamacandelo entsimbi ye-I-beam enobude obukhulu beflange kunye nobubanzi obuncinci beflange, nto leyo ebangela amandla aphezulu kunye nomthamo wokuthwala umthwalo. Iindidi ezahlukeneyo zentsimbi ezinqamlezileyo zineempawu zazo zoyilo lwesakhiwo; ke ngoko, kwiiprojekthi ezithile zobunjineli, uhlobo olufanelekileyo kufuneka lukhethwe ngokusekelwe kwiimfuno zokwenyani.

UBUKHULU BEMVELISO

| Ukutyunjwa | Unt Ubunzima kg/m) | Icandelo Eliqhelekileyo ukukhulisa mm | Icandelo UAma (cm² | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE28 | AA | 61.3 | 264.0 | 280.0 | 7.0 | 10.0 | 24.0 | 78.02 |

| A | 76.4 | 270.0 | 280.0 | 80 | 13.0 | 24.0 | 97.26 | |

| B | 103 | 280.0 | 280.0 | 10.5 | 18.0 | 24.0 | 131.4 | |

| M | 189 | 310.0 | 288.0 | 18.5 | 33.0 | 24.0 | 240.2 | |

| HE300 | AA | 69.8 | 283.0 | 300.0 | 7.5 | 10.5 | 27.0 | 88.91 |

| A | 88.3 | 200.0 | 300.0 | 85 | 14.0 | 27.0 | 112.5 | |

| B | 117 | 300.0 | 300.0 | 11.0 | 19.0 | 27.0 | 149.1 | |

| M | 238 | 340.0 | 310.0 | 21.0 | 39.0 | 27.0 | 303.1 | |

| HE320 | AA | 74.3 | 301.0 | 300.0 | 80 | 11.0 | 27.0 | 94.58 |

| A | 97.7 | 310.0 | 300.0 | 9.0 | 15.5 | 27.0 | 124.4 | |

| B | 127 | 320.0 | 300.0 | 11.5 | 20.5 | 27.0 | 161.3 | |

| M | 245 | 359.0 | 309.0 | 21.0 | 40.0 | 27.0 | 312.0 | |

| HE340 | AA | 78.9 | 320.0 | 300.0 | 85 | 11.5 | 27.0 | 100.5 |

| A | 105 | 330.0 | 300.0 | 9.5 | 16.5 | 27.0 | 133.5 | |

| B | 134 | 340.0 | 300.0 | 12.0 | 21.5 | 27.0 | 170.9 | |

| M | 248 | 377.0 | 309.0 | 21.0 | 40.0 | 27.0 | 315.8 | |

| HE360 | AA | 83.7 | 339.0 | 300.0 | 9.0 | t2.0 | 27.0 | 106.6 |

| A | 112 | 350.0 | 300.0 | 10.0 | 17.5 | 27.0 | 142.8 | |

| B | 142 | 360.0 | 300.0 | 12.5 | 22.5 | 27.0 | 180.6 | |

| M | 250 | 395.0 | 308.0 | 21.0 | 40.0 | 27.0 | 318.8 | |

| HE400 | AA | 92.4 | 3780 | 300.0 | 9.5 | 13.0 | 27.0 | 117.7 |

| A | 125 | 390.0 | 300.0 | 11.0 | 19.0 | 27.0 | 159.0 | |

| B | 155 | 400.0 | 300.0 | 13.5 | 24.0 | 27.0 | 197.8 | |

| M | 256 | 4320 | 307.0 | 21.0 | 40.0 | 27.0 | 325.8 | |

| HE450 | AA | 99.8 | 425.0 | 300.0 | 10.0 | 13.5 | 27.0 | 127.1 |

| A | 140 | 440.0 | 300.0 | 11.5 | 21.0 | 27.0 | 178.0 | |

| B | 171 | 450.0 | 300.0 | 14.0 | 26.0 | 27.0 | 218.0 | |

| M | 263 | 4780 | 307.0 | 21.0 | 40.0 | 27.0 | 335.4 | |

| Ukumisela | Iyunithi Ubunzima kg/m) | Icandelo Eliqhelekileyo Ububanzi (mm) | ICandelo Indawo (cm²) | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE50 | AA | 107 | 472.0 | 300.0 | 10.5 | 14.0 | 27.0 | 136.9 |

| A | 155 | 490.0 | 300.0 | t2.0 | 23.0 | 27.0 | 197.5 | |

| B | 187 | 500.0 | 300.0 | 14.5 | 28.0 | 27.0 | 238.6 | |

| M | 270 | 524.0 | 306.0 | 21.0 | 40.0 | 27.0 | 344.3 | |

| HE550 | AA | t20 | 522.0 | 300.0 | 11.5 | 15.0 | 27.0 | 152.8 |

| A | 166 | 540.0 | 300.0 | t2.5 | 24.0 | 27.0 | 211.8 | |

| B | 199 | 550.0 | 300.0 | 15.0 | 29.0 | 27.0 | 254.1 | |

| M | 278 | 572.0 | 306.0 | 21.0 | 40.0 | 27.0 | 354.4 | |

| HE60 | AA | t29 | 571.0 | 300.0 | t2.0 | 15.5 | 27.0 | 164.1 |

| A | 178 | 500.0 | 300.0 | 13.0 | 25.0 | 27.0 | 226.5 | |

| B | 212 | 600.0 | 300.0 | 15.5 | 30.0 | 27.0 | 270.0 | |

| M | 286 | 620.0 | 305.0 | 21.0 | 40.0 | 27.0 | 363.7 | |

| HE650 | AA | 138 | 620.0 | 300.0 | t2.5 | 16.0 | 27.0 | 175.8 |

| A | 190 | 640.0 | 300.0 | t3.5 | 26.0 | 27.0 | 241.6 | |

| B | 225 | 660.0 | 300.0 | 16.0 | 31.0 | 27.0 | 286.3 | |

| M | 293 | 668.0 | 305.0 | 21.0 | 40.0 | 27.0 | 373.7 | |

| HE700 | AA | 150 | 670.0 | 300.0 | 13.0 | 17.0 | 27.0 | 190.9 |

| A | 204 | 600.0 | 300.0 | 14.5 | 27.0 | 27.0 | 260.5 | |

| B | 241 | 700.0 | 300.0 | 17.0 | 32.0 | 27.0 | 306.4 | |

| M | 301 | 716.0 | 304.0 | 21.0 | 40.0 | 27.0 | 383.0 | |

| HE800 | AA | 172 | 770.0 | 300.0 | 14.0 | 18.0 | 30.0 | 218.5 |

| A | 224 | 790.0 | 300.0 | 15.0 | 28.0 | 30.0 | 285.8 | |

| B | 262 | 800.0 | 300.0 | 17.5 | 33.0 | 30.0 | 334.2 | |

| M | 317 | 814.0 | 303.0 | 21.0 | 40.0 | 30.0 | 404.3 | |

| HE800 | AA | 198 | 870.0 | 300.0 | 15.0 | 20.0 | 30.0 | 252.2 |

| A | 252 | 800.0 | 300.0 | 16.0 | 30.0 | 30.0 | 320.5 | |

| B | 291 | 900.0 | 300.0 | 18.5 | 35.0 | 30.0 | 371.3 | |

| M | 333 | 910.0 | 302.0 | 21.0 | 40.0 | 30.0 | 423.6 | |

| HEB1000 | AA | 222 | 970.0 | 300.0 | 16.0 | 21.0 | 30.0 | 282.2 |

| A | 272 | 0.0 | 300.0 | 16.5 | 31.0 | 30.0 | 346.8 | |

| B | 314 | 1000.0 | 300.0 | 19.0 | 36.0 | 30.0 | 400.0 | |

| M | 349 | 1008 | 302.0 | 21.0 | 40.0 | 30.0 | 444.2 | |

IIMBONAKALO

Iinxalenye zentsimbi ze-HEA, HEB, kunye ne-HEM ziintlobo zemiqadi yentsimbi ye-IPE yaseYurophu esemgangathweni (icandelo elinqamlezileyo elinomfanekiso we-I) esetyenziswa kakhulu ekwakheni nasebunjineli bezakhiwo. Nazi iimpawu eziphambili zohlobo ngalunye:

Icandelo lentsimbi le-HEA (IPN):

Ububanzi kunye nobukhulu beflegi enkulu

Ifanelekile kwizakhiwo ezinemithwalo enzima

Inika amandla okuthwala umthwalo kunye namandla okugoba

Icandelo lentsimbi le-HEB (IPB):

Ububanzi kunye nobukhulu beflegi ephakathi

Isetyenziswa ngeendlela ezahlukeneyo, isetyenziswa rhoqo kwizakhiwo ezahlukeneyo

Idibanisa amandla kunye neenzuzo ezikhaphukhaphu

Icandelo lentsimbi ye-HEM:

Ukuphakama kweflegi enkulu kunye nobubanzi obuncinci

Inika amandla aphezulu kunye nomthamo wokuthwala umthwalo

Ifanelekile kwizakhiwo ezinemithwalo enzima kunye noxinzelelo oluphezulu

EI-NHIntsimbi Emile

Udidi: EN10034:1997 EN10163-3:2004

Inkcazo: I-HEA HEB kunye ne-HEM

Umgangatho: EN

UHLOLO LWEMVELISO

Iimfuno eziphambili zokuhlola intsimbi enomfanekiso we-H ziquka ezi zinto zilandelayo:

Umgangatho weNkangeleko: Inkangeleko yentsimbi enomfanekiso we-H kufuneka ihlangabezane nemigangatho efanelekileyo kunye neemfuno zabathengi. Umphezulu kufuneka ube mpuluswa kwaye ulingane, ungabi nazimbobo ezibonakalayo, imikrwelo, amabala okugqwala, kunye nezinye iziphene.

Ubukhulu beJiyometri: Ubude, ububanzi, ukuphakama, ubukhulu bewebhu, kunye nobukhulu beflange yentsimbi enomfanekiso we-H kufuneka ihambelane nemigangatho efanelekileyo kunye neemfuno zabathengi.

Ukuthe tye: Ukuthe tye kwentsimbi enomfanekiso we-H kufuneka kuhlangabezane nemigangatho efanelekileyo kunye neemfuno zabathengi. Oku kunokuqinisekiswa ngokulinganisa ukufana kweziphelo zombini okanye ukusebenzisa igeyiji yokuthe tye.

Ukujika: Ukujika kwentsimbi enomfanekiso we-H kufuneka kuhlangabezane nemigangatho efanelekileyo kunye neemfuno zabathengi. Oku kunokuqinisekiswa ngokulinganisa ukulingana kwamacala okanye ukusebenzisa isixhobo sokuvavanya ukujika.

Ukuphambuka kobunzima: Ubunzima bentsimbi enomfanekiso we-H kufuneka buhlangabezane nemigangatho efanelekileyo kunye neemfuno zabathengi. Ukuphambuka kobunzima kungajongwa ngokubulinganisa.

Ulwakhiwo lweeKhemikhali: Ukuba intsimbi enomfanekiso we-H ifuna ukuwelda okanye olunye uhlobo lokucubungula, ulwakhiwo lwayo lweekhemikhali kufuneka luhlangabezane nemigangatho efanelekileyo kunye neemfuno zabathengi.

Iipropati zoomatshini: Iipropati zoomatshini zentsimbi enomfanekiso we-H kufuneka zihlangabezane nemigangatho efanelekileyo kunye neemfuno zabathengi, kubandakanya amandla okutsalwa, amandla okukhupha, ukunwebeka, njl.njl.

Uvavanyo Olungatshabalalisiyo: Ukuba kufuneka uvavanyo olungatshabalalisiyo kwintsimbi enomfanekiso we-H, kufuneka lwenziwe ngokwemigangatho efanelekileyo kunye neemfuno zabathengi ukuqinisekisa ukuba umgangatho wayo wangaphakathi uyahlangabezana neemfuno.

Ukupakishwa kunye nokulebhelishwa: Ukupakishwa kunye nokulebhelishwa kwentsimbi enomfanekiso we-H kufuneka kuhambelane nemigangatho efanelekileyo kunye neemfuno zabathengi, okwenza kube lula ukuthuthwa kunye nokugcinwa kwayo.

Ngamafutshane, xa kuhlolwa intsimbi enobume be-H, zonke ezi mfuno zingasentla kufuneka ziqwalaselwe ngokupheleleyo ukuqinisekisa ukuba umgangatho uyahlangabezana nemigangatho efanelekileyo kunye neemfuno zabathengi, ngaloo ndlela kubonelelwa abasebenzisi ngeemveliso zentsimbi enobume be-H ezikumgangatho ophezulu.

ISICELO

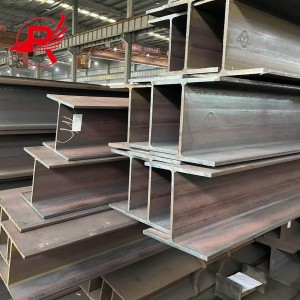

Imisebe ye-HEA, HEB, kunye ne-HEMZineentlobo ngeentlobo zezicelo kushishino lobunjineli bokwakha nolwakhiwo. Ezinye zeendlela ezisetyenziswa kakhulu ziquka:

- Iiprojekthi Zokwakha: Ezi nxalenye zentsimbi zisetyenziswa kakhulu ekwakheni izakhiwo zorhwebo nezemizi-mveliso, zibonelela ngenkxaso yemigangatho, uphahla, kunye nezinye izakhiwo ezithwala imithwalo.

Ubunjineli beBhulorho: Zisetyenziswa ekwakhiweni kwebhulorho, zixhasa idekhi yebhulorho kunye nezinye izinto zokwakha.

Izixhobo zeMizi-mveliso: Icandelo lentsimbi le-HEA, i-HEB, kunye ne-HEM lisetyenziswa kakhulu ekwakhiweni kwezakhiwo zoshishino ezifana neendawo zokugcina impahla, iifektri kunye neendawo zokugcina izinto.

Izakhelo zoLwakhiwo: Zingasetyenziselwa ukwakha izakhelo zolwakhiwo lwezakhiwo ezinkulu kunye neeprojekthi zeziseko zophuhliso, zibonelela ngenkxaso kwiindonga, iifacade, kunye nezinye izinto zolwakhiwo.

Inkxaso yeZixhobo: La macandelo entsimbi angasetyenziselwa ukuxhasa oomatshini abanzima kunye nezixhobo kwiindawo ezahlukeneyo zoshishino.

Iiprojekthi zeZiseko zoPhuhliso: Icandelo lentsimbi le-HEA, i-HEB, kunye ne-HEM likwasetyenziswa ekwakhiweni kweeprojekthi zeziseko zophuhliso ezifana neetonela, izikhululo zeenqwelo-moya kunye nezikhululo zombane.

Ngamafutshane, la macandelo entsimbi adlala indima ebalulekileyo kwiiprojekthi ezahlukeneyo zokwakha nobunjineli, enika inkxaso eqinileyo nethembekileyo yokwakha. Ukuguquguquka kwawo, amandla, kunye nomthamo wawo wokuthwala umthwalo kuwenza abe zizinto eziyimfuneko kuyilo lwezakhiwo zanamhlanje kunye neziseko zophuhliso.

UKUPAKISHA NOKUTHUMELA

Ukupakishwa kunye noKhuselo

Ukupakishwa ngokufanelekileyo kubalulekile ukuqinisekisa umgangatho wentsimbi enobume be-ASTM A36 H ngexesha lokuthuthwa nokugcinwa kwayo: Sebenzisa imitya/iibhendi zentsimbi ezinamandla aphezulu ukubopha imiqadi yentsimbi ngokukhuselekileyo ukuthintela ukushukuma nokonakala; Sebenzisa izinto ezimelana nemozulu ezifana neeplastiki okanye iitarpaulini ezingangeni manzi ukukhusela ukufuma kunye nothuli, ukuthintela ukugqwala.

Ukulayisha, Ukukhulula, kunye nokukhusela

Phatha imiqadi yentsimbi epakishiweyo ngononophelo xa ulayisha kwaye ukhulula: Sebenzisa izixhobo zokuphakamisa ezifanelekileyo ezifana neeforklift okanye iicrane ukuqinisekisa ukhuseleko kunye nokusebenza kakuhle; Xa ulayisha, sasaza imiqadi yentsimbi ngokulinganayo kwaye uyilungelelanise ngokuchanekileyo ukuze uthintele umonakalo wesakhiwo; Emva kokulayisha, qinisa umthwalo ngeentambo, amatyathanga, njl.njl., ukuqinisekisa uzinzo kunye nokuthintela ukushukuma ngexesha lokuthuthwa. Esi sishwankathelo sifutshane sigxile kwiinkqubo ezibalulekileyo kunye neemfuno, okwenza kube lula ukuqonda ulwazi olubalulekileyo ngokukhawuleza. Ukuba unqwenela ukwenza lula naliphi na icandelo okanye ukongeza iinkcukacha ezithile (ezifana neentlobo zezinto zokukhusela), nceda usazise.

FAQ

1. Ndingayifumana njani ikowuteshini kuwe?

Ungasishiyela umyalezo, kwaye siza kuphendula yonke imiyalezo ngexesha elifanelekileyo.

2. Ngaba uza kuzihambisa iimpahla ngexesha elifanelekileyo?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni ophezulu kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3. Ndingafumana iisampulu ngaphambi kokuba ndi-odole?

Ewe, ewe. Ngokwesiqhelo iisampulu zethu zisimahla, singazivelisa ngeesampulu zakho okanye ngemizobo yobugcisa.

4. Ithini imiqathango yakho yokuhlawula?

Ixesha lethu lokuhlawula eliqhelekileyo yidiphozithi ye-30%, kwaye intsalela ihambelana ne-B/L. EXW, FOB, CFR, CIF.

5. Ngaba uyayamkela into yokuhlolwa ngumntu wesithathu?

Ewe siyamkela ngokupheleleyo.

6. Siyithemba njani inkampani yakho?

Siziingcali kwishishini lentsimbi kangangeminyaka emininzi njengomthengisi wegolide, ikomkhulu likwiphondo laseTianjin, samkelekile ukuphanda ngazo zonke iindlela, nangayiphi na indlela.