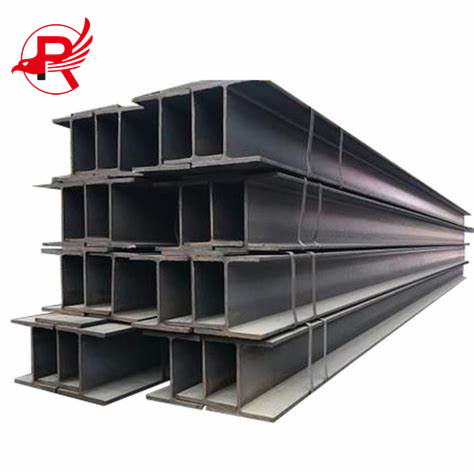

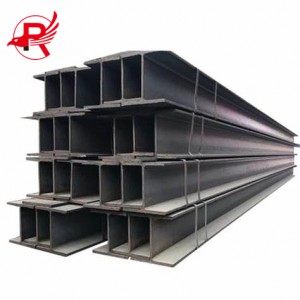

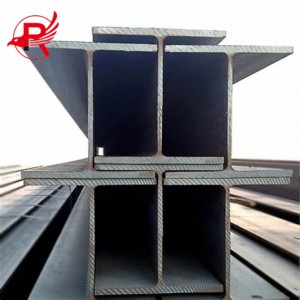

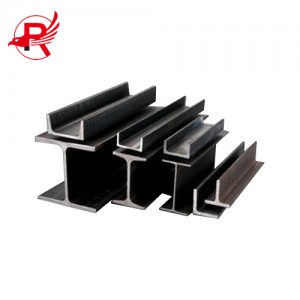

Intsimbi Emile okwe-ASTM H W4x13, W30x132, W14x82 | Intsimbi ye-H yentsimbi ye-A36

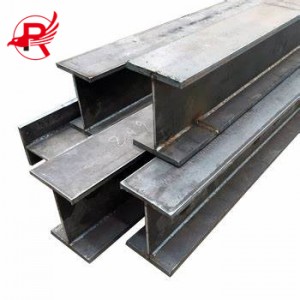

Imiqadi yeFlange ebanzi, eyaziwa ngokuba yi-I-beam okanye i-H-beam, ngumqadi wentsimbi wolwakhiwo oneflange ebanzi, elungeleleneyo kunye newebhu ehambelanayo. Olu hlobo luvumela umqadi ukuba uxhase imithwalo enzima kwaye umelane namandla okugoba nokujika. Imiqadi yeflange ebanzi isetyenziswa rhoqo kwizicelo zokwakha, zoshishino, kunye neendawo zokuhlala ukuxhasa izakhiwo zokwakha, iibhulorho, kunye nezixhobo ezinkulu. Zifumaneka ngobukhulu obahlukeneyo kwaye zinokwenziwa ngokwezifiso ukuhlangabezana neemfuno ezithile zeprojekthi. Imiqadi yeflange ebanzi yenziwa ngokwemigangatho yeshishini kunye neenkcukacha ukuqinisekisa amandla aphezulu, ukuqina, kunye nozinzo kwiiprojekthi ezahlukeneyo zokwakha kunye neziseko zophuhliso.

INKQUBO YOKUVELISA IMVELISO

Ukulungiselela kwangaphambili:

Ukunyibilikisa:

I-Billet yokuphosa eqhubekayo:

Ukuqengqeleka Okushushu:

Gqibezela ukuqengqeleka:

Ukupholisa:

Ukuhlolwa koMgangatho kunye nokuPakisha:

UBUKHULU BEMVELISO

IINZUZO

I-Flange ebanzi, zisetyenziswa kwizicelo ezahlukeneyo zesakhiwo ukuxhasa imithwalo enzima kwiindawo ezinde. Uyilo lweflange ebanzi lubonelela ngomthamo obalaseleyo wokuthwala umthwalo kunye nokumelana nokugoba nokujika.Imisebe ye-WZifumaneka ngobukhulu obahlukeneyo kwaye zisetyenziswa kakhulu kwizakhiwo, kwizityalo zoshishino, kwiibhulorho, nakwiiprojekthi zeziseko zophuhliso. Uyilo lwazo luhambelana nemigangatho kunye neenkcukacha zoshishino ukuqinisekisa ukuthembeka kwesakhiwo kunye nokhuseleko. Iimpawu eziqhelekileyo ziquka amandla aphezulu, ukuguquguquka, kunye nokukwazi ukwenziwa ngokwezifiso ngokulula ngokweemfuno ezithile zeprojekthi.

IPROJEKTHI

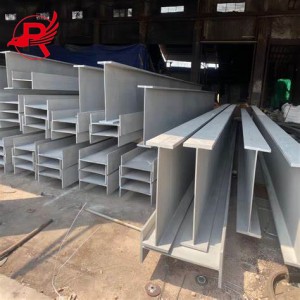

Inkampani yethu inamava eminyaka emininzi kurhwebo lwangaphandle lweUmqadi we-W4x13. Isixa-mali esipheleleyo see-H-beams ezithunyelwa eKhanada ngeli xesha singaphezulu kwe-8,000,000 yeetoni. Umthengi uza kuhlola iimpahla ezikwifektri. Nje ukuba iimpahla ziphumelele uhlolo, intlawulo iya kwenziwa kwaye ithunyelwe. Ukususela oko kwaqala ukwakhiwa kwale projekthi, inkampani yethu ilungiselele ngononophelo isicwangciso semveliso kwaye yaqokelela ukuhamba kwenkqubo ukuqinisekisa ukuhanjiswa ngexesha elifanelekileyo kweprojekthi yentsimbi enomfanekiso we-H. Ekubeni isetyenziswa kwizakhiwo ezinkulu zefektri, iimfuno zokusebenza kweemveliso zentsimbi enomfanekiso we-H ziphezulu kunokumelana nokugqwala kwentsimbi enomfanekiso we-H yeqonga leoyile. Ke ngoko, inkampani yethu iqala kumthombo wemveliso kwaye yonyusa ulawulo lokwenza intsimbi, ukuphoswa okuqhubekayo kunye neenkqubo ezinxulumene nokuqengqeleka. Yomeleza umgangatho weemveliso zeenkcukacha ezahlukeneyo ukuze zilawulwe ngokufanelekileyo kuzo zonke iinkalo, ukuqinisekisa izinga lokupasa le-100% leemveliso ezigqityiweyo. Ekugqibeleni, umgangatho wokucubungula intsimbi enomfanekiso we-H waqatshelwa ngabathengi ngazwi linye, kwaye intsebenziswano yexesha elide kunye neenzuzo zamazwe ngamazwe zafezekiswa ngokusekelwe ekuthembekeni.

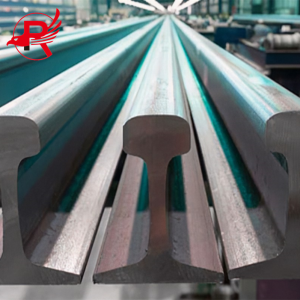

UHLOLO LWEMVELISO

Kwezinto eziqhelekileyoUmqadi we-W30x132okanyeI-H-Beam S275jr, ukuba umxholo wekhabhoni uphakathi kwe-0.4% ukuya kwi-0.7%, kwaye iimfuno zepropathi yoomatshini aziphezulu kakhulu, ukulungelelanisa kungasetyenziswa njengonyango lokugqibela lobushushu. Okokuqala, kufuneka kuveliswe iintsika zentsimbi ezinemilo enqamlezileyo. Emva kokwahlulwahlulwa komsebenzi kumzi-mveliso, emva koko ziyahlanganiswa, zilinganiswe, kwaye zihlolwe ukuqinisekisa ukuba iimveliso zifanelekile kwaye emva koko zithuthwe ziye kwindawo yokwakha ukuze zifakwe ii-splicing. Ngexesha lenkqubo yokufakelwa ii-splicing, ukufakwa kwee-splicing kufuneka kwenziwe ngokuhambelana neenkqubo ezifanelekileyo. , Kuphela ngale ndlela umgangatho wemveliso unokuqinisekiswa ngokufanelekileyo. Emva kokuba ukufakwa kugqityiwe, iziphumo zokugqibela zokufakwa kufuneka zihlolwe. Emva kokuhlolwa, amaza e-ultrasonic kufuneka asetyenziswe ukwenza uvavanyo olungonakalisiyo lwangaphakathi, ukuze iziphene ezibangelwe ngexesha lokuhlanganiswa zisuswe ngokufanelekileyo. Ukongeza, ukucubungula iintsika ezinqamlezileyo nako kuyafuneka. Ngexesha lokufakwa kwesakhiwo sentsimbi, kufuneka kuqala ukhethe i-annotation eqhelekileyo, uvale inethi yokulawula, uze wenze umlinganiselo othe nkqo wokuphakama kwekholamu ephezulu. Emva koko, ukufuduka komphezulu wekholamu kunye nesakhiwo sentsimbi kufuneka kucutshungulwe ukuze kuguqulwe kakhulu, kwaye emva koko iziphumo ezithe tyaba kakhulu kunye neziphumo zokuhlolwa kwekholamu esezantsi zicutshungulwe ngokupheleleyo. Ukucutshungulwa kweenyawo ezixineneyo kufuneka kwenziwe emva kokuba indawo yekholamu yentsimbi imiselwe. Ngokuhlalutya idatha yokucubungula, ukuma kwekholamu yentsimbi kuyalungiswa kwakhona. Emva kokuba ukufakwa kugqityiwe, iirekhodi zokulinganisa kufuneka zihlolwe kwaye iingxaki zokuwelda kufuneka zihlolwe. Ukongeza, ukuvalwa kweendawo zokulawula kufuneka kuhlolwe kwakhona. Okokugqibela, umzobo wedatha yokulawula kwangaphambili kwekholamu yentsimbi esezantsi kufuneka udwetshwe.

ISICELO

Iflengi ebanziimiqadiZineentlobo ngeentlobo zezicelo kubunjineli bokwakha kunye nolwakhiwo. Ezinye zeendlela ezisetyenziswa kakhulu ziquka:

Ukwakhiwa kwesakhiwo: Imiqadi ebanzi yeflange isetyenziswa njengamalungu aphambili okuthwala umthwalo ekwakhiweni kwezakhiwo, inika inkxaso kwimigangatho, uphahla, kunye nokuzinza kwesakhiwo ngokubanzi.

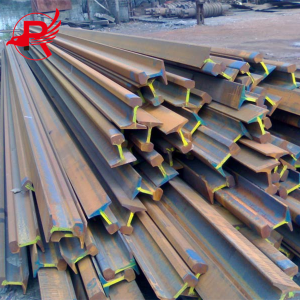

Iibhulorho: Iiplanga ezibanzi zisetyenziswa rhoqo ekwakheni izakhiwo zeebhulorho, zibonelela ngenkxaso yeendlela, iindlela zabahambi ngeenyawo, kunye nemigca kaloliwe.

Izakhiwo zemizi-mveliso: Ezi planga zisetyenziswa kakhulu ekwakhiweni kwezakhiwo zoshishino, ezinje ngeendawo zokugcina impahla, izityalo zokuvelisa, kunye namaziko okuhambisa izinto, ukuxhasa izixhobo ezinzima kunye noomatshini.

Iiprojekthi zeziseko zophuhliso: Imiqadi ebanzi yeflange ibalulekile ekwakhiweni kweeprojekthi zeziseko zophuhliso ezifana neetonela, izikhululo zeenqwelo-moya, kunye namabala emidlalo, inika inkxaso yesakhiwo kwiindawo ezinkulu kunye nemithwalo enzima.

Izakhiwo zenkxaso: Iibhanti zeflange ezibanzi zisetyenziswa njengeentsika zenkxaso kunye neebhanti kwizicelo ezahlukeneyo zesakhiwo, zibonelela ngamandla kunye nozinzo kwisakhiwo siphela.

Ngokubanzi, imiqadi yeflange ebanzi zizinto ezinokuguquguquka ezisetyenziswa kwiiprojekthi ezahlukeneyo zokwakha apho amandla, uzinzo, kunye nomthamo wokuthwala umthwalo kubalulekile.

UKUPAKISHA NOKUTHUMELA

Ukupakisha:

Iinqwaba zePhepha eziQokelelweyo ngokuZinzileyo: Faka intsimbi ye-H-section kakuhle nangokuzinzileyo, uqinisekise ukuba zilungelelaniswe ukuze kuthintelwe ukungazinzi. Sebenzisa iibhanti zokubopha okanye zokupakisha ukuze uqinise iinqwaba kwaye uphephe ukufuduka ngexesha lokuthuthwa.

Ukusebenzisa Izinto Zokupakisha Ezikhuselekileyo: Songa iimfumba zamaphepha ezipakishwe ngezinto ezingangenisi manzi ezifana neplastiki okanye iphepha elingangeni manzi ukuze uzikhusele emanzini, kumswakama nakwezinye izinto ezingqongileyo. Oku kunceda ekuthinteleni umhlwa nokugqwala.

Uthutho:

Ukukhetha Iindlela Zokuthutha Ezifanelekileyo: Ngokusekelwe kubungakanani nobunzima beenqwaba zeeshiti, khetha iindlela zokuthutha ezifanelekileyo ezifana neelori ezisicaba, iikhonteyina okanye iinqanawa. Cinga ngezinto ezifana nomgama, ixesha, iindleko kunye nazo naziphi na iimfuno zomthetho zokuthutha.

Ukusebenzisa Izixhobo Zokuphakamisa Ezifanelekileyo: Sebenzisa izixhobo zokuphakamisa ezifanelekileyo ezifana neekhreyini, iiforklift okanye iiloja ukulayisha nokukhupha iinqwaba zentsimbi zohlobo lwe-U. Qinisekisa ukuba izixhobo ezisetyenzisiweyo zinamandla aneleyo okuthwala umthwalo ukuphakamisa ngokukhuselekileyo ubunzima beenqwaba zephepha.

Ukukhusela Iimpahla: Sebenzisa imitya, izixhasi okanye ezinye iindlela ezifanelekileyo zokubopha ngokuqinileyo iimfumba zephepha ezipakishiweyo kwizithuthi zothutho, ukuthintela ukushelela, ukutyibilika okanye ukuwa ngexesha lokuthuthwa.

AMANDLA ENKAMPANI

Yenziwe eTshayina, inkonzo yodidi oluphezulu, umgangatho ophezulu, idume kwihlabathi liphela

1. Isiphumo sesikali: Inkampani yethu inekhonkco elikhulu lokubonelela ngempahla kunye nomzi-mveliso omkhulu wentsimbi, ifikelela kwiziphumo zesikali kwezothutho kunye nokuthengwa kwempahla, kwaye iba yinkampani yentsimbi edibanisa imveliso kunye neenkonzo.

2. Ukwahluka kwemveliso: Ukwahluka kwemveliso, nayiphi na intsimbi oyifunayo ingathengwa kuthi, ikakhulu ibandakanya izakhiwo zentsimbi, iireyile zentsimbi, iipali zeshiti zentsimbi, izibiyeli ze-photovoltaic, intsimbi yetshaneli, iikhoyili zesinyithi zesilicon kunye nezinye iimveliso, nto leyo eyenza ukuba iguquguquke ngakumbi Khetha uhlobo lwemveliso oyifunayo ukuhlangabezana neemfuno ezahlukeneyo.

3. Ubonelelo oluzinzileyo: Ukuba nomgca wemveliso ozinzileyo kunye nochungechunge lobonelelo kunokubonelela ngobonelelo oluthembekileyo ngakumbi. Oku kubaluleke kakhulu kubathengi abafuna intsimbi eninzi.

4. Impembelelo yophawu: Banempembelelo ephezulu yophawu kunye nemarike enkulu

5. Inkonzo: Inkampani enkulu yentsimbi edibanisa ukwenziwa ngokwezifiso, uthutho kunye nemveliso

6. Ukhuphiswano lwamaxabiso: ixabiso elifanelekileyo

*Thumela i-imeyile ku[i-imeyile ikhuselwe]ukuze ufumane ikowuteshini yeeprojekthi zakho