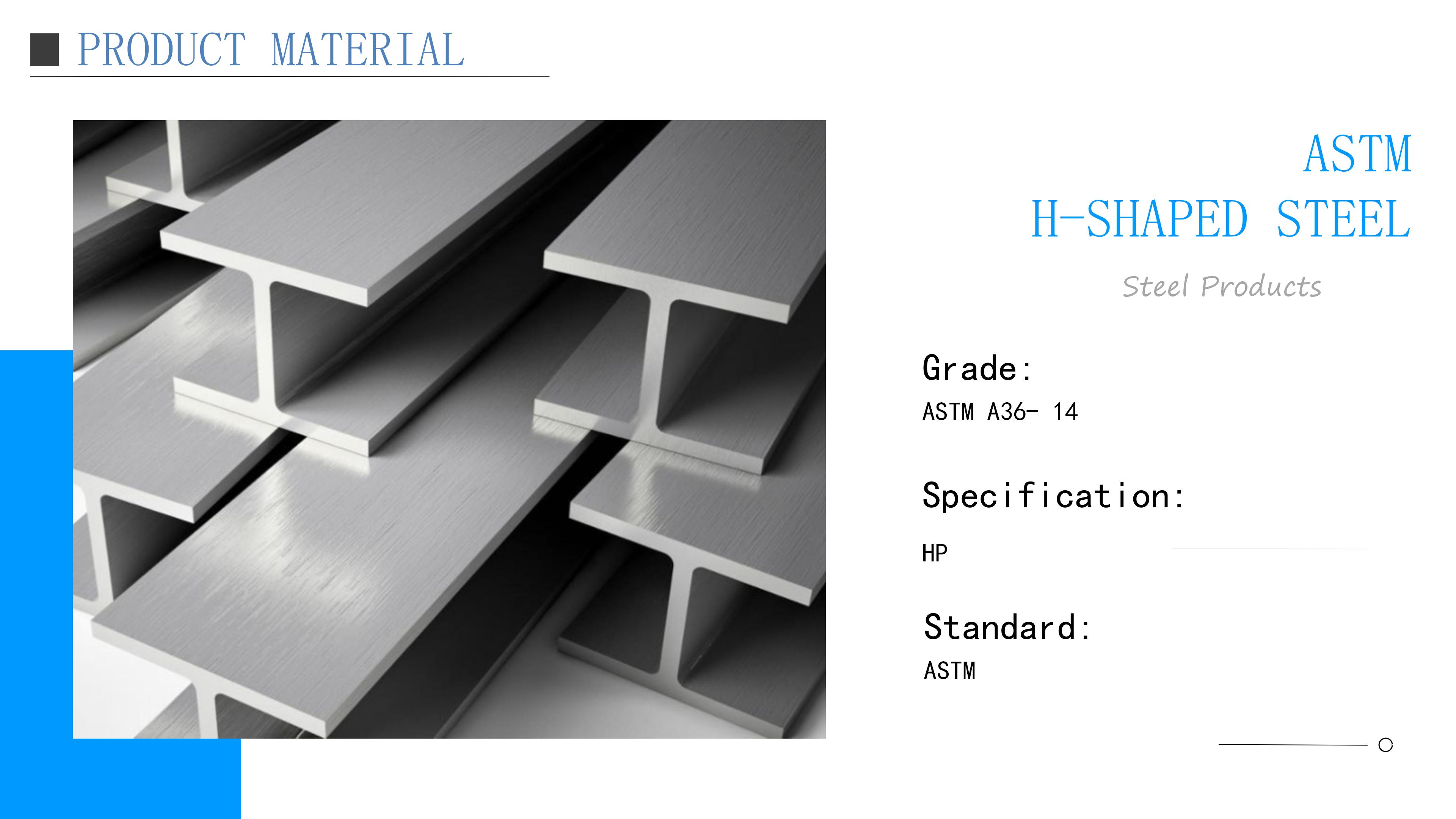

I-ASTM i-H-Shaped Steel Structural Beams

Ubunzima besakhiwo sokukhanya: Xa kuthelekiswa nezakhiwo ezilula, kunciphisa ubunzima besakhiwo sezakhiwo zekhonkrithi, kunciphisa ukuyila kwamandla angaphakathi angaphakathi, kwaye kusetyenziselwa ukwakha iziseko zesakhiwo kunye neemfuno eziphantsi zokucwangcisa, isakhiwo esilula kunye neendleko eziphantsi.

INKQUBO YOKUVELISWA KWEMVELISO

- Ukufudumeza kweMathiriyeli ekrwada: I-billet ye-rectangular yondliwa kwisithando somlilo kwaye ishushu kwi-1200-1250 ° C ide ifike kwi-plastic state.

- Ukuqengqeleka okurhabaxa: Ukuqengqeleka kokuqala kwenziwa kwi-roll-roll roughing Mill, ilandelwa yi-universal roughing mill ukuvelisa i-milo yokuqala ethi "I", kunye nobubanzi be-flange buhlengahlengiswa ngaxeshanye.

- Ukugqiba ukuqengqeleka: I-universal finishing mill isebenzisa iipaseji ezininzi ze-precision rolling ukumisela imilinganiselo ye-cross-sectional dimensions, kwaye i-edge roller inquma iiphelo ze-flange.

- Ukupholisa kunye nokuLungisa: Icandelo lensimbi eshushu lipholile kwiqondo lokushisa kwigumbi kwibhedi yokupholisa, emva koko lilungiswe ukugoba kunye nokujija usebenzisa i-universal straightener.

- Ukugqiba Ukuhlola: Sawed ubude, amacandelo ahlolwe umgangatho womphezulu, ukunyamezela kwe-dimensional, kunye neempawu zoomatshini. Amacandelo amkelekileyo ayaphawulwa kwaye agcinwe.

UBUKHULU BEMVELISO

| INGCACISO YEH-BEAM | |

| 1. Ubungakanani | 1) Ukutyebas:5-34mmokanye yenziwe ngokwezifiso |

| 2)Ubude:6-12m okanye ngokwezifiso | |

| 3) Ukutyeba kwewebhu:6mm-16mm okanye ngokwezifiso | |

| 2. Umgangatho: | JIS ASTM DIN EN GB |

| 3.Izinto eziphathekayo | Q195 Q235 Q345 A36 S235JR S335JR S275JR |

| 4. Indawo yomzi-mveliso wethu | eTianjin, eTshayina |

| 5. Ukusetyenziswa: | 1)isakhiwo esiphakamileyo samashishini |

| 2) Izakhiwo kwiiNdawo eziChasene nenyikima | |

| 3) iibhulorho ezinkulu ezinexesha elide | |

| 6. Ukwaleka: | 1) Ibared2) Ipeyintiwe emnyama (ingubo yevarnish) 3) igalvanized |

| 7. Ubuchule: | ishushu iqengqeleke |

| 8. Uhlobo: | Imfumba yohlobo lwe-H |

| 9. Ubume beCandelo: | H |

| 10. Ukuhlolwa: | Ukuhlolwa komthengi okanye ukuhlolwa ngumntu wesithathu. |

| 11. Ukuhanjiswa: | Isikhongozelo, Isikhephe esikhulu. |

| 12. Malunga noMgangatho Wethu: | 1) Akukho monakalo, akukho bent2) Isimahla kwi-oiled&marking 3) Zonke iimpahla zinokujongwa ngokuhlolwa komntu wesithathu ngaphambi kokuthunyelwa |

| Ukwahlula ibn (ubunzulu x id | Iyunithi Ubunzima kg/m) | Sandard Sectional Ubungakanani (mm) | Okwexeshana Indawo cm² | ||||

| W | H | B | 1 | 2 | r | A | |

| HP8x8 | 53.5 | 203.7 | 207.1 | 11.3 | 11.3 | 10.2 | 68.16 |

| HP10x10 | 62.6 | 246.4 | 255.9 | 10.5 | 10.7 | t2.7 | 70.77 |

| 85.3 | 253.7 | 259.7 | 14.4 | 14.4 | 127 | 108.6 | |

| HP12x12 | 78.3 | 2992 | 305.9 | 11.0 | 11.0 | 15.2 | 99.77 |

| 93.4 | 303.3 | 308.0 | 13.1 | 13.1 | 15.2 | 119.0 | |

| 111 | 308.1 | 310.3 | 15.4 | 15.5 | 15.2 | 140.8 | |

| 125 | 311.9 | 312.3 | 17.4 | 17.4 | 15.2 | 158.9 | |

| HP14x14% | 108.0 | 345.7 | 370.5 | 12.8 | t2.8 | 15.2 | 137.8 |

| 132.0 | 351.3 | 373.3 | 15.6 | 15.6 | 15.2 | 168.4 | |

| 152.0 | 355.9 | 375.5 | 17.9 | 17.9 | 15.2 | 193.7 | |

| 174.0 | 360.9 | 378.1 | 20.4 | 20.4 | 15.2 | 221.5 | |

I-ADVANTAGE

II-Structural Steel H Beamibonisa iimpawu zamandla amangalisayo, iyenza ibe lolona khetho lufanelekileyo kwiiprojekthi apho umthamo wokuthwala umthwalo ubaluleke kakhulu. Ukongezelela, ukusetyenziswa kwentsimbi eshushu eqengqelekayo kwinkqubo yokuvelisa kwandisa ukuqina kunye nokomelela kwale miqadi, nto leyo eyenza ukuba imelane kakhulu ne-warping, twist, and corrosion.

IPROJEKTHI

Inkampani yethu ineminyaka emininzi yamava kurhwebo lwangaphandleIntsimbi eshushu eqengqelekayo yeH. Umthamo opheleleyo we-H-beams othunyelwe eCanada ngeli xesha ufikelele kwi-8 yezigidi zeetoni. Abathengi bahlole iimveliso kwifektri yethu, kwaye emva kokuhlolwa ngempumelelo, intlawulo yenziwa ngaphambi kokuthunyelwa. Ukusukela oko iprojekthi iqalile, inkampani yethu icwangcise ngokucokisekileyo izicwangciso zemveliso kwaye yaqulunqa ukuhamba kwenkqubo ukuqinisekisa ukuhanjiswa kwangexesha kwee-H-beams. Ngenxa yokuba ii-H-beams zisetyenziswa kwiifektri ezinkulu, iimfuno zokusebenza ziphezulu kunokumelana nokubola kwe-H-beams esetyenziswa kwiiplatifti zeoli. Ke ngoko, inkampani yethu ibeke phambili imveliso kwasekuqaleni, ukomeleza ulawulo lokwenza intsimbi, ukuphosa okuqhubekayo, kunye neenkqubo zokuqengqeleka. Oku komelezile ulawulo lomgangatho olusebenzayo kuzo zonke iinkcukacha zemveliso, ukuqinisekisa i-100% yezinga lemveliso egqibeleleyo. Ekugqibeleni, umgangatho we-H-beams uzuze ukuvunywa ngamxhelo mnye kubathengi bethu, ukukhuthaza ubuhlakani bexesha elide, obuluncedo ngokulinganayo olusekwe ekuthembaneni.

UKUHLOLWA KWEMVELISO

Iimfuno zeH Intsimbi emileUkuhlola ikakhulu kubandakanya le miba ilandelayo:

Umgangatho wokubonakala: Umgangatho wembonakalo yentsimbi ye-H kufuneka ihambelane nemigangatho efanelekileyo kunye neemfuno zokuyalela. Umphezulu kufuneka ube bushelelezi kwaye ube tyaba, ngaphandle kwezibonda ezicacileyo, imikrwelo, umhlwa kunye nezinye iziphene.

Imilinganiselo yejometri: Ubude, ububanzi, ukuphakama, ubukhulu bewebhu, ubukhulu be-flange kunye nobunye ubungakanani bentsimbi efana ne-H kufuneka ihambelane nemigangatho efanelekileyo kunye neemfuno zokuodola.

Igophe: Ukugoba kweH Icandelo Beamkufuneka ihambelane nemigangatho efanelekileyo kunye neemfuno zokuodola. Inokubonwa ngokulinganisa ukuba iindiza kuzo zombini iziphelo zentsimbi efana ne-H zihambelana okanye zisebenzisa imitha yokugoba.

I-twist: I-twist yentsimbi e-H kufuneka ihambelane nemigangatho efanelekileyo kunye neemfuno zokuyalela. Inokubonwa ngokulinganisa ukuba icala lentsimbi emise okwe-H lithe nkqo okanye ngemitha ye-twist.

Ukutenxa ubunzima: Ubunzima beH Beam Pilekufuneka ihambelane nemigangatho efanelekileyo kunye neemfuno zokuodola. Ukuphambuka kobunzima kunokubonwa ngobunzima.

Ukubunjwa kweMichiza: Ukuba ii-H-beams zifuna i-welding okanye enye inkqubo, ukubunjwa kweekhemikhali kufuneka kuhambelane nemigangatho efanelekileyo kunye neenkcukacha zomyalelo.

IiPropati zoomatshini: Iipropati zomatshini zemiqadi ye-H kufuneka zihambelane nemigangatho efanelekileyo kunye neenkcukacha zolandelelwano, kubandakanywa amandla okuqina, indawo yesivuno, kunye nobude.

Uvavanyo olungonakalisiyo: Ukuba ii-H-beams zifuna uvavanyo olungonakalisi, kufuneka luqhutywe ngokuhambelana nemigangatho efanelekileyo kunye neenkcukacha zomyalelo wokuqinisekisa umgangatho wazo wendalo.

Ukupakishwa kunye nokuMakisha: Ukupakishwa kunye nokumakishwa kwe-H-beams kufuneka kuhambelane nemigangatho efanelekileyo kunye neenkcukacha ze-odolo ukwenzela ukuba kube lula ukuthuthwa nokugcinwa.

Isishwankathelo, ezi mfuno zingentla kufuneka ziqwalaselwe ngokupheleleyo xa kuhlolwa ii-H-beams ukuqinisekisa ukuba umgangatho wabo uhlangabezana nemigangatho efanelekileyo kunye neenkcukacha zomyalelo, ukubonelela abasebenzisi ngemveliso ephezulu ye-H-beam.

ISICELO

Izakhiwo zokwakha: Zisebenza njengemiqadi kunye neentsika kwimizi-mveliso, izakhiwo eziphakamileyo, namabala emidlalo, zithwala imithwalo emi nkqo nethe tyaba.

Ubunjineli beebhulorho: Ukukhonza njengemiqadi ephambili kunye nemiqadi enqamlezileyo yohola wendlela kunye neebhulorho zikaloliwe, ezifanelekileyo kwiimfuno zokuthwala umthwalo omkhulu.

Ukwenziwa koomatshini: Ukuvelisa iziseko kunye nezakhelo zezixhobo ezinzima, ukubonelela ngenkxaso ezinzileyo.

Iziseko zophuhliso zikamasipala: Yakha izakhiwo ezixhasayo kwiindlela ezihamba phantsi komhlaba kunye neetonela, kunye namathambo eebhilibhodi kunye neepali zezibane zesitrato.

Ugcino kunye nolungiselelo: Ukwenza iintsika ezinkulu zokurhangqa kunye nemiqadi enqamlezileyo ukuxhasa ubunzima bemigangatho emininzi yomthwalo.

Amandla: Ukukhonza njengemiqadi ephambili yeenqaba ze-injini yomoya kunye neeracks ze-photovoltaic, ezifanelekileyo kwiindawo zangaphandle ezinzima.

UKUPAKISHA NOKUTHUMELA

Ngaphambi kokuthunyelwa, qinisekisa ukuba ii-H-beams zipakishwe ngokufanelekileyo kwaye zikhuselekile ukukhusela ukunyakaza okanye ukungqubana ngexesha lokuthutha. Sebenzisa izinto ezifanelekileyo zokupakisha kunye nezixhobo zokukhusela, ezifana neentambo zetsimbi kunye ne-skids zokhuni, ukuqinisekisa ukuzinza kunye nokukhuseleka kwee-H-beams.

Khetha indlela yothutho efanelekileyo ngokusekwe kubungakanani, ubunzima, kunye nomgama we-H-beams. Kwizithuthi ezihamba umgama omfutshane, kucetyiswa ukuba kuthuthwe ezindleleni kusetyenziswa iilori okanye ezinye izithuthi ezindleleni. Ukuthutha umgama omde, ukuthuthwa kukaloliwe kunokufaneleka ngakumbi, njengoko kunokuthwala umthamo omkhulu we-H-beams kwaye unikeze ukuzinza okukhulu. Kurhwebo lwamazwe ngamazwe okanye ukuthutha elwandle umgama omde, ukuthuthwa kwamanzi kunokuba lukhetho olulungileyo. Kwiimeko ezingxamisekileyo okanye xa ixesha liyinto ebalulekileyo, ukuthuthwa kweenqwelo moya kunokhetho.

AMANDLA ENKAMPANI

Yenziwe eTshayina, inkonzo yodidi lokuqala, umgangatho wokusika, owaziwa kwihlabathi jikelele

1. Isiphumo sesikali: Inkampani yethu inokubonelela ngempahla enkulu kunye nefektri enkulu yensimbi, ifezekisa iziphumo zesikali ekuthuthweni nasekuthengeni, kwaye ibe yinkampani yentsimbi edibanisa imveliso kunye neenkonzo.

2. Ukwahluka kwemveliso: Ukwahluka kwemveliso, nayiphi na insimbi oyifunayo ingathengwa kuthi, ngokuyininzi ibandakanyeka kwizakhiwo zetsimbi, iileyili zensimbi, iipali zentsimbi, iibrakethi ze-photovoltaic, i-channel steel, iikhoyili zensimbi ze-silicon kunye nezinye iimveliso, okwenza kube lula ngakumbi Khetha uhlobo lwemveliso olufunwayo ukuhlangabezana neemfuno ezahlukeneyo.

3. Unikezelo oluzinzileyo: Ukuba nomgca wemveliso ozinzile kunye nekhonkco lokubonelela kunokubonelela ngokubonelela okuthembekileyo. Oku kubaluleke ngakumbi kubathengi abafuna ubuninzi bentsimbi.

4. Impembelelo yeBrand: Yiba nempembelelo ephezulu yophawu kunye nemarike enkulu

5. Inkonzo: Inkampani enkulu yensimbi edibanisa ukulungelelanisa, ukuthutha kunye nemveliso

6. Ukukhuphisana kwexabiso: ixabiso elifanelekileyo

*Thumela i-imeyile kuyo[i-imeyile ekhuselweyo]ukufumana ikowuti yeeprojekthi zakho

FAQ

1. Ndingasifumana njani isicaphulo kuwe ?

Ungasishiya umyalezo, kwaye siya kuphendula yonke imiyalezo ngexesha.

2.Uza kuzisa iimpahla ngexesha?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3.Ndingakwazi ukufumana iisampulu phambi kokuodola?

Ewe kunjalo. Ngokwesiqhelo iisampulu zethu zisimahla, sinokuvelisa ngeesampulu zakho okanye imizobo yobugcisa.

4.Ithini imiqathango yakho yentlawulo?

Ixesha lethu lesiqhelo lokuhlawula yi-30% yediphozithi, kwaye siphumle kwi-B/L. EXW, FOB,CFR,CIF.

5.Ngaba uyalwamkela uhlolo lweqela lesithathu?

Ewe siyavuma ngokupheleleyo.

6.Siyithemba njani inkampani yakho?

Sisebenza ngokukhethekileyo kwishishini lentsimbi iminyaka njengomthengisi wegolide, ikomkhulu lihlala kwiphondo laseTianjin, wamkelekile ukuphanda ngazo zonke iindlela.