I-GB 1200 × 2400 Steel Grating isetyenziselwa ukwakhiwa okukhulu kunye nokwakhiwa komgangatho ophezulu

| Igama lemveliso | Igridi yentsimbi enamazinyo |

| Isitayile soyilo | Imodem |

| Izinto eziphathekayo | Ukutshisa okushushu, okwenziwe ngokwezifiso |

| Ubunzima | 7-100kg |

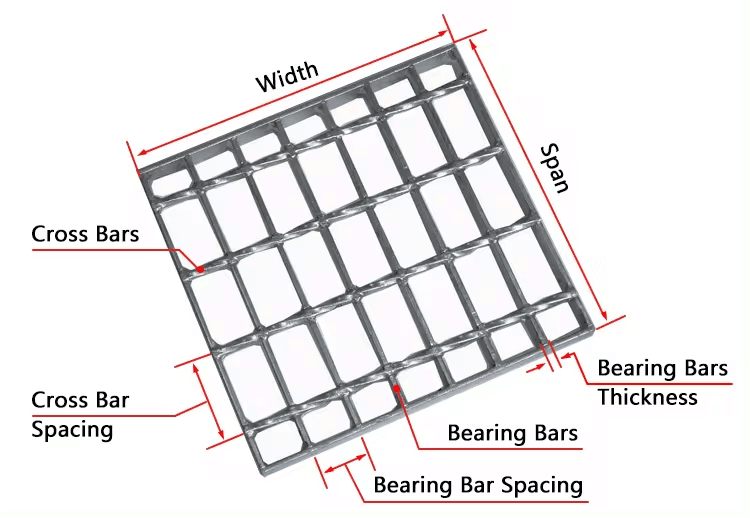

| Ibha yokuthwala | 253/ 255/303/325/ 405/553/655 |

| Ipitshi yebha yokuthwala | 30mm 50mm 100mm |

| Uphawu | Ukumelana okugqwesileyo kokulwa nokugqwala, okuchasene nokutyibilika |

| Impahla engekasilwa | Intsimbi Eshushu Edityiweyo Egqunywe Ngesinyithi Q235 |

| Umgangatho | Imigangatho yaseYurophu, GB/T13912-2002, BS729, AS1650 |

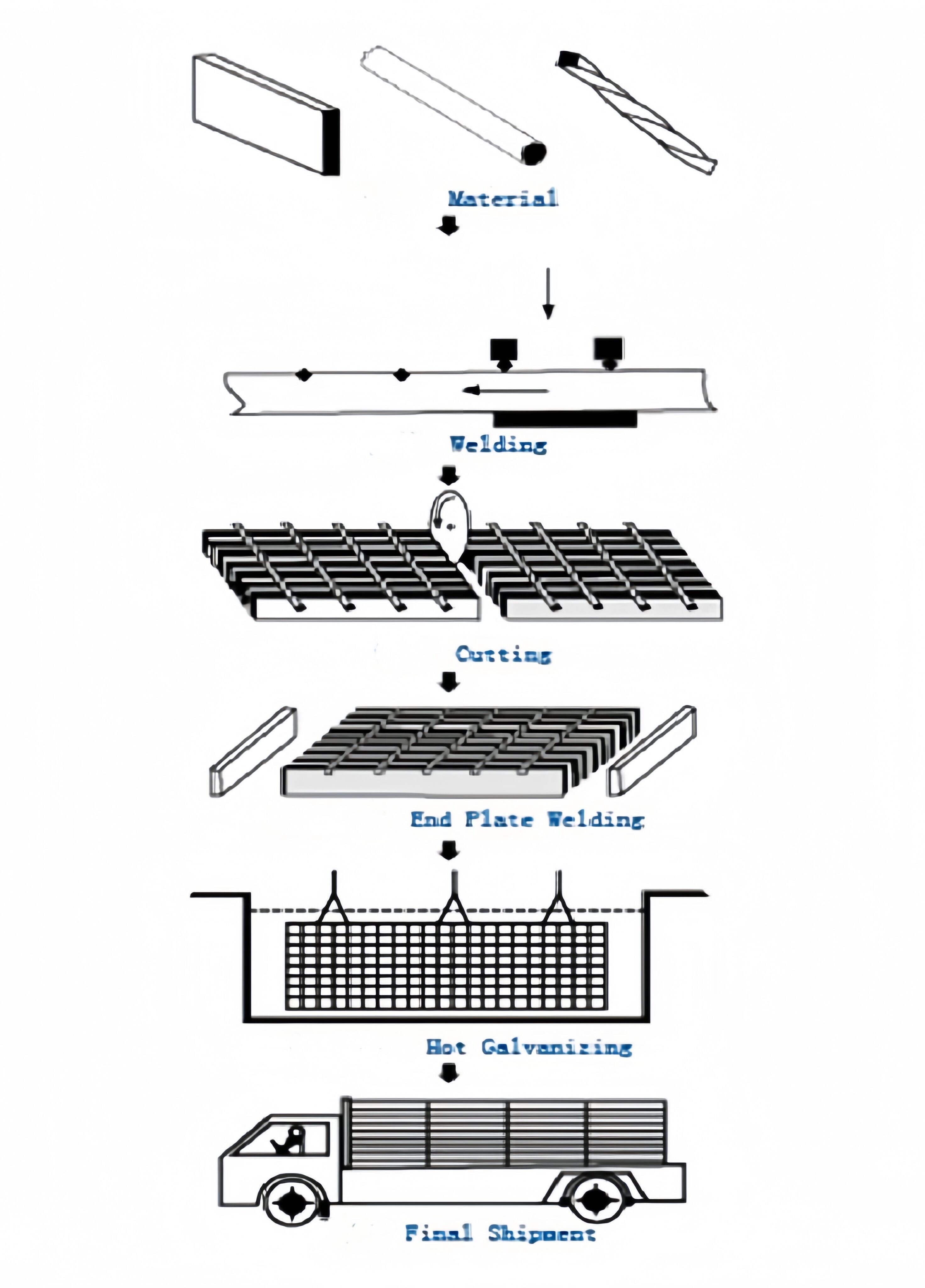

| Indlela yokuWelda | Ukuwelda kokumelana noxinzelelo oluzenzekelayo |

| Ikholamu yetshathi | ingenanto yeempahla phakathi | Indawo ephilayo | Iinkcukacha ze-Layisha i-flat mesh (ububanzi kunye nobukhulu) | |||||||

| 20x3 | 25x3 | 32x3 | 403 | 20x5 | 25x5 | |||||

| 1 | 30 | 100 | G20330100 | E25230H00 | C32380F100 | G40230100 | E205/30100 | E255/307100 | ||

| 50 | G20230/50 | C253/20/50 | C2233050 | 640340100 | C205/00/50 | C255/30/50 | ||||

| 2 | 40 | 100 | 6203/401100 | 8253/40100 | E323/401100 | 640340100 | 8205/40/100 | 5255/40/100 | ||

| 50 | G20340/50 | G250/40/50 | G223/4050 | G403140/50 | 205/4/50 | G255/4050 | ||||

| 3 | 60 | 50 | G203460/50 | C25360/50 | 5253/6050 | 3403480150 | C205/60/50 | G255/60150 | ||

| Ikholamu yetshathi | ingenanto yeempahla phakathi | Indawo ephilayo | Iinkcukacha ze-Layisha i-flat mesh (ububanzi kunye nobukhulu) | |||||||

| 32×5 | 40x5 | 45x5 | 5045 | 55×5 | 80x5 | |||||

| 1 | 30 | 100 | G325301100 | G40530H00 | C45580100 | G50530100 | G555/30100 | E805/30/100 | ||

| 50 | G325/30/50 | C405/20/50 | G455/3050 | S505/30/50 | 55500/50 | G605/8050 | ||||

| 2 | 40 | 100 | 8325401100 | 840540100 | 455/40100 | G50540100 | 8555/40/100 | 2605/40/100 | ||

| 50 | G32540/50 | C405/40/50 | G4554050 | G505/40/50 | E555/40/50 | G605/40150 | ||||

| 3 | 60 | 50 | G225.6051 | C405/6A/50 | G4556050 | G50560/50 | 6555/6050 | G6056051 | ||

Uthango lweNtsimbi lweGB

Umgangatho: GB/T 700-2006

YB/T4001.1-2007

Iimbonakalo

I-ASTM A36 grating yentsimbiYenziwe ngentsimbi enekhabhoni ephantsi enokumelana nokudityaniswa kakuhle kunye nokwakheka okuhle. Yaziwa ngamandla ayo aphezulu kunye nomthamo wayo obalaseleyo wokuthwala umthwalo. Oku kwenza i-A36 steel grating ifaneleke kakhulu kwizicelo ezinzima kwiindawo zoshishino, ezifana neendawo zokwakha, izityalo zokuvelisa, kunye nezakhiwo ze-petrochemical. Inika ukumelana okuphuculweyo nxamnye nempembelelo, ubushushu, kunye nokugqwala, okuqinisekisa ubomi obude nakwiindawo ezinzima.

I-grill yentsimbi egayiweyoyenziwe ngokugquma intsimbi ngomaleko we-zinc, enika ukhuseleko oluphezulu ekugqwaleni nasekugqwaleni. Inkqubo yokuqinisa i-galvanization iphucula ixesha elide le-grating, okwenza ifaneleke kwiindawo zangaphandle okanye kwiindawo ezichatshazelwe kukufuma kunye nezinto ezirhabaxa. I-galvanized grating isetyenziswa rhoqo kwiindawo zokuhamba ngeenyawo, kwiinkqubo zokukhupha amanzi, kunye namaqonga, apho umphezulu wayo ongatyibilikiyo wongeza umaleko owongezelelweyo wokhuseleko.

Umahluko ophambili phakathi kwe-ASTM A36 steel grating kunye ne-galvanized steel grating usekwe kwiimpawu zazo zokumelana nokugqwala. Nangona i-ASTM A36 grating inika umgangatho osisiseko wokuxhathisa ukugqwala, i-galvanized coating kwi-steel grating inika ukhuseleko oluphezulu, oluyandisa kakhulu ubomi bayo. I-galvanized steel grating iyacetyiswa xa kusetyenziswe apho ukuthintela ukugqwala kubaluleke kakhulu.

Isicelo

I-steel grating, imveliso eguquguqukayo nehlala ixesha elide, ifumene udumo olukhulu ngenxa yezicelo zayo ezininzi kumashishini ahlukeneyo. I-steel grating yenziwe ngee-bars okanye iipleyiti zentsimbi ezidibeneyo, inika amandla angaqhelekanga, uzinzo, kunye nokukwazi ukuhambisa amanzi.

1. Icandelo lezemizi-mveliso:

Icandelo lemizi-mveliso lisebenzisa kakhulu i-steel grating ngenxa yokuqina kwayo okungenakuthelekiswa nanto kunye neempawu zokhuseleko. Isetyenziswa kakhulu njengomgangatho kwiifektri nakwiindawo zokugcina impahla, inika umphezulu ozinzileyo woomatshini abanzima kwaye inika abasebenzi indawo ekhuselekileyo. I-steel grating ikwasetyenziselwa ii-catwalks, amaqonga aphakanyisiweyo, kunye nee-mezzanines, inika indlela ekhuselekileyo yabasebenzi yokufikelela kwiindawo ezahlukeneyo ngaphakathi kwesakhiwo.

2. Ishishini Lokwakha:

Kwishishini lokwakha, i-grit yentsimbi ayibalulekanga. Isetyenziswa kakhulu njengeqonga le-scaffolding, inika indawo yokusebenza eqinileyo nekhuselekileyo kubasebenzi abakwiindawo eziphakamileyo. Ngenxa yomthamo wayo ophezulu wokuthwala umthwalo, i-grit yentsimbi iqinisekisa ukhuseleko lwabasebenzi bokwakha ngexesha lezigaba ezahlukeneyo zeprojekthi. Ngaphezu koko, i-grit yentsimbi inokwenziwa ngokwezifiso ukuhlangabezana neemfuno ezithile, nto leyo eyenza ukuba ibe lukhetho olukhethwayo lokwakha iindlela zokuhamba, izitebhisi, kunye nezigqubuthelo zokukhupha amanzi ngaphakathi kwezakhiwo.

3. Icandelo lezoThutho:

Ngenxa yomlinganiselo wayo obalaseleyo wokuqina nobunzima, i-steel grating isetyenziswa kakhulu kwicandelo lezothutho. Isetyenziswa kakhulu ekudaleni iindlela zokuhamba eziqinileyo, ezingatyibilikiyo kunye neendawo zokunyathela izitebhisi kwiindawo zokulungisa izithuthi, kwizikhululo zeenqwelo-moya, kwizikhululo zikaloliwe, nakwiindawo zokulungisa iinqanawa. Ezi zisombululo ze-grating ziphucula ukhuseleko kwaye zivumela ukuhamba kakuhle, nokuba imeko yemozulu imbi.

4. Ishishini laMandla neoyile:

Ishishini lamandla neoyile lixhomekeke kakhulu kwi-grill yentsimbi ukuze ihlale ixesha elide kwaye imelane nokugqwala. I-grill yentsimbi isetyenziswa kakhulu kwiindawo zokucoca ioyile, kwizikhululo zamandla, nakwizibonelelo zokucubungula iikhemikhali. Isebenza njengesisombululo esifanelekileyo somgangatho, ngakumbi kwiindawo ezichatshazelwe lulwelo, iikhemikhali, kunye namaqondo obushushu aphezulu, ukuqinisekisa ukhuseleko lwabasebenzi kunye nokuthintela iingozi.

5. Izicelo zorhwebo nezoyilo:

I-steel grating ikwafumana indlela yayo kwiiprojekthi zorhwebo kunye nezokwakha. Ubuhle bayo obuhle, kunye neenzuzo zayo zokusebenza, kuyenza ibe lukhetho oluhle kakhulu lokwenza ii-facades ezinesitayile, i-sunshades, kunye nezikrini zokuhombisa. I-steel grating ingasetyenziswa njengezinto zobugcisa kwiindawo zasezidolophini, inika zombini ubuhle bokubonakalayo kunye nokusebenza.

UMBONISO WEMVELISO

UKUPAKISHA NOKUTHUMELA

UTYELELO LWABATHENGI

FAQ

1. Ndingayifumana njani ikowuteshini kuwe?

Ungasishiyela umyalezo, kwaye siza kuphendula yonke imiyalezo ngexesha elifanelekileyo.

2. Ngaba uza kuzihambisa iimpahla ngexesha elifanelekileyo?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni ophezulu kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3. Ndingafumana iisampulu ngaphambi kokuba ndi-odole?

Ewe, ewe. Ngokwesiqhelo iisampulu zethu zisimahla, singazivelisa ngeesampulu zakho okanye ngemizobo yobugcisa.

4. Ithini imiqathango yakho yokuhlawula?

Ixesha lethu lokuhlawula eliqhelekileyo yidiphozithi ye-30%, kwaye intsalela imele i-B/L.

5. Ngaba uyayamkela into yokuhlolwa ngumntu wesithathu?

Ewe siyamkela ngokupheleleyo.

6. Siyithemba njani inkampani yakho?

Siziingcali kwishishini lentsimbi kangangeminyaka emininzi njengomthengisi wegolide, ikomkhulu likwiphondo laseTianjin, samkelekile ukuphanda ngazo zonke iindlela, nangayiphi na indlela.