Isakhiwo seNdawo yokuGcina iNsimbi esakhiwe ngokukhawuleza esakhiwe kwangaphambili Isakhiwo seNdawo yokuGcina iNsimbi yeHangar

Nangona uxinano lwentsimbi luphezulu kunolo lwezinye izinto zokwakha, amandla alo aphezulu kakhulu. Phantsi koxinzelelo olufanayo, isakhiwo sentsimbi sinobunzima obuncinci kwaye singenziwa sibe sisakhiwo esinobubanzi obukhulu.

Ulwakhiwo lwangaphakathi lwentsimbi lufana kwaye luyi-isotropic. Ukusebenza okwenyani kwesakhiwo sentsimbi kuvumelana kakuhle neziphumo zokubala zethiyori ezisetyenzisiweyo, ngoko ke ukuthembeka kwesakhiwo kuphezulu.

*Thumela i-imeyile ku[i-imeyile ikhuselwe]ukuze ufumane ikowuteshini yeeprojekthi zakho

| Uluhlu lwezinto | |

| Iprojekthi | |

| Ubungakanani | Ngokweemfuno zoMthengi |

| Isakhelo soBume beNtsimbi esiPhambili | |

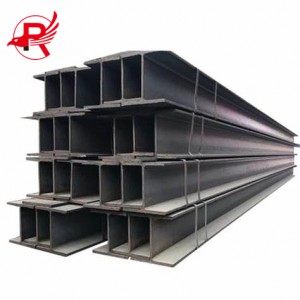

| Ikholamu | Intsimbi yeCandelo le-H eWelded ye-Q235B, Q355B |

| Umqadi | Intsimbi yeCandelo le-H eWelded ye-Q235B, Q355B |

| Isakhelo soLwakhiwo lweNsimbi yeSibini | |

| I-Purlin | Uhlobo lwentsimbi ye-Q235B C kunye ne-Z |

| Isixhasi sedolo | Uhlobo lwentsimbi ye-Q235B C kunye ne-Z |

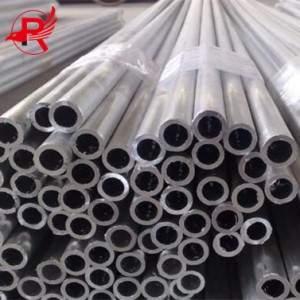

| Ityhubhu yokubopha | Umbhobho weNtsimbi ojikelezayo we-Q235B |

| I-brace | Ibha ejikelezileyo ye-Q235B |

| Inkxaso ethe nkqo nethe tye | I-Q235B Angle Steel, iRound Bar okanye iSteel Pipe |

INKQUBO YOKUVELISA IMVELISO

IINZUZO

Ziziphi iingenelo kunye neengxaki zobunjineli besakhiwo sentsimbi?

1. Le nto inamandla aphezulu kwaye inobunzima obuphantsi

Intsimbi inamandla aphezulu kunye ne-elastic modulus ephezulu. Xa ithelekiswa nekhonkrithi kunye nomthi, umlinganiselo woxinano lwayo kunye namandla okuvelisa uphantsi kakhulu. Ke ngoko, phantsi kweemeko ezifanayo zoxinzelelo, isakhiwo sentsimbi sinecandelo elincinci lezinto, ubunzima obulula, ukuthuthwa nokufakelwa lula, kwaye kufanelekile kwiindawo ezinkulu, ukuphakama okuphezulu, kunye nemithwalo enzima. Ulwakhiwo.

2. Intsimbi iqinile, iplastiki ilungile, inezinto ezifanayo, kwaye inokuthembeka okuphezulu kwesakhiwo.

Ifanelekile ukumelana nefuthe kunye nemithwalo eguqukayo, kwaye inokumelana okuhle nokushukuma komhlaba. Ulwakhiwo lwangaphakathi lwentsimbi lufana kwaye lusondele kumzimba ofana nowe-isotropic. Ukusebenza okwenyani kwesakhiwo sentsimbi kuhambelana kakhulu nethiyori yokubala. Ke ngoko, isakhiwo sentsimbi sinokuthembeka okuphezulu.

3. Ukwenziwa nokufakelwa kwesakhiwo sentsimbi kwenziwa ngoomatshini abaphezulu

Izixhobo zesakhiwo sentsimbi kulula ukuzenza kwiifektri kwaye zihlanganiswe kwiindawo zokwakha. Ukuveliswa kwezixhobo zesakhiwo sentsimbi ngoomatshini kumzi-mveliso kunobunono obuphezulu, ukusebenza kakuhle kwemveliso, ukuhlanganiswa kwendawo yokwakha ngokukhawuleza, kunye nexesha elifutshane lokwakha. Isakhiwo sentsimbi sesona sakhiwo siphucukileyo kakhulu kwimizi-mveliso.

4. Isakhiwo sentsimbi sisebenza kakuhle ekutywineni

Ekubeni isakhiwo esitshixiweyo singavalwa ngokupheleleyo, singenziwa sibe ziindawo zokufaka umoya oxinzelelweyo, amachibi amakhulu eoyile, imibhobho yoxinzelelo, njl.njl. enomoya oqinileyo nokuqina kwamanzi.

5. Ulwakhiwo lwentsimbi alunabushushu kodwa alunamlilo

Xa ubushushu bungaphantsi kwe-150°C, iimpawu zentsimbi azitshintshi kangako. Ke ngoko, isakhiwo sentsimbi sifanelekile kwiindawo zokusebenzela ezishushu, kodwa xa umphezulu wesakhiwo uphantsi kobushushu obuyi-150 degrees.°C, kufuneka ikhuselwe ziiphaneli zokuthintela ubushushu. Xa ubushushu bungama-300℃-400℃Amandla kunye ne-elastic modulus yentsimbi zombini ziyancipha kakhulu. Xa ubushushu bumalunga nama-600 degrees°C, amandla entsimbi adla ngokuba zero. Kwizakhiwo ezineemfuno ezikhethekileyo zomlilo, isakhiwo sentsimbi kufuneka sikhuselwe ngezinto ezichasene nomlilo ukuphucula umlinganiselo wokumelana nomlilo.

IDIPOZITHI

Iiphahla zihlala ziquka iileya ezingangeni manzi, iiphaneli zophahla, imiqadi, iipayipi zezixhobo, iisilingi, njl. Iiphaneli zophahla azipheleli nje ekuthwaleni umthwalo, kodwa zikwayindlela yokudibanisa eyahlula indawo ephezulu nendawo engaphandle.

Uphahla lolona phahla luphezuluIzakhiwo zeSitayileIfanele ihlangabezane neemfuno zokusebenza ezifanelekileyo kwaye ibonelele ngendawo efanelekileyo yangaphakathi yesakhiwo.

Umsebenzi kunye neemfuno zophahla: Uphahla lolona phahla luphezulu lwendlu, oluquka uphahla kunye nesakhiwo esixhasayo. Umsebenzi wokukhusela uphahla kukuthintela ukuhlaselwa yimvula yendalo, ikhephu kunye neziphepho zesanti kunye nempembelelo yemitha yelanga. Kwelinye icala, kufuneka ithwale umthwalo okwinxalenye ephezulu yophahla, kubandakanya umthwalo womoya kunye nekhephu, ubunzima bophahla, kunye nobunzima bezinto ezinokubakho kunye nabantu, kwaye iludlulisele eludongeni. Ke ngoko, iimfuno zophahla kufuneka zibe namandla kwaye zihlale ixesha elide, zibe nobunzima obulula, kwaye zibe neempawu zokuthintela amanzi, ezingatshiyo, zokuthintela ubushushu kunye nezokuthintela ubushushu. Kwangaxeshanye, izinto kufuneka zibe lula, zibe lula ukwakhiwa, kwaye zikwazi ukusebenzisana nesakhiwo siphela ukuze sibe nembonakalo entle.

UHLOLO LWEMVELISO

Izakhiwo zentsimbiUqhagamshelo lukhonkco oluphambili kubunjineli besakhiwo sentsimbi. Umgangatho woqhagamshelo uchaphazela ngokuthe ngqo ukhuseleko kunye nokuzinza kweprojekthi yonke yesakhiwo sentsimbi. Ukuhlolwa koqhagamshelo lwesakhiwo sentsimbi kubandakanya ikakhulu ezi zinto zimbini zilandelayo:

1. Ukuhlolwa komgangatho wokuwelda: kubandakanya ukuhlolwa komgangatho wokubonakala kokuwelda, iziphene zangaphakathi kunye nezinye izalathisi zokuvavanya ukuba umgangatho wokuwelda uyahlangabezana na neemfuno ezimiselweyo.

2. Ukuchonga uqhagamshelo lwebholiti enamandla aphezulu: Iibholiti ezinamandla aphezulu zezinye zeendlela zoqhagamshelo ezisetyenziswa kakhulu kuqhagamshelo lwesakhiwo sentsimbi. Ukuvavanya umgangatho woqhagamshelo kunye nenqanaba lokuqinisa kunokuqinisekisa uzinzo kunye nokhuseleko loqhagamshelo.

IPROJEKTHI

Inkampani yethu idla ngokuthumela kwamanye amazweIzakhiwo zentsimbi ezilungisiweyoiimveliso eziya eMelika nakumazwe akuMzantsi-mpuma weAsia. Sithathe inxaxheba kwenye yeeprojekthi eMelika enommandla opheleleyo omalunga ne-543,000 square metres kunye nokusetyenziswa okupheleleyo kweetoni ezingama-20,000 zentsimbi. Emva kokuba iprojekthi igqityiwe, iya kuba yisakhiwo sentsimbi esidibanisa imveliso, indawo yokuhlala, iofisi, imfundo kunye nokhenketho.

ISICELO

Intsimi yokwakha:Izakhiwo zeSitayile seNsimbizisetyenziswe kakhulu kwizakhiwo zanamhlanje, kuquka izakhiwo eziphakamileyo, izityalo zoshishino, izakhiwo zorhwebo, amabala emidlalo, iiholo zemiboniso, izikhululo, iibhulorho, njl. Izakhiwo zentsimbi zineengenelo zobunzima obulula, amandla aphezulu, isantya sokwakha esikhawulezayo, kunye nokumelana okuhle nokunyikima komhlaba. Zinokuhlangabezana neemfuno zezakhiwo zanamhlanje zokhuseleko lwesakhiwo, ukonga, kunye nokukhuselwa kokusingqongileyo.

Ubunjineli beebhulorho: Izakhiwo zentsimbi zisetyenziswe kakhulu kubunjineli beebhulorho, kuquka iibhulorho zendlela, iibhulorho zikaloliwe, iibhulorho zabahamba ngeenyawo, iibhulorho ezihlala kwiintambo, iibhulorho ezixhonyiweyo, njl. Izakhiwo zentsimbi zineengenelo zobunzima obulula, amandla aphezulu, ulwakhiwo olulula, kunye nokuqina okuhle, kwaye zinokuhlangabezana neemfuno zobunjineli beebhulorho ukuze kukhuseleke kwaye kongiwe isakhiwo.

Intsimi yokwenziwa koomatshini: Izakhiwo zentsimbi zisetyenziswe kakhulu kwicandelo lokwenziwa koomatshini, kubandakanya izixhobo ezahlukeneyo zoomatshini, oomatshini bokushicilela, ii-oven zoshishino, ii-rolling mills, ii-cranes, ii-compressors, izixhobo zokudlulisa, njl. Izakhiwo zentsimbi zineengenelo zokuqina okuphezulu, ukuqina okuhle, kunye nokucutshungulwa okulula, kwaye zinokuhlangabezana neemfuno zokuchaneka kwezixhobo kunye nokuzinza kwicandelo lokwenziwa koomatshini.

UKUPAKISHA NOKUTHUMELA

Ulwakhiwo lwentsimbi Isakhiwo sesinyithikufuneka zipakishwe ngexesha lokuthunyelwa ukuze kukhuselwe ukhuseleko kunye nokuthembeka kweempahla kunye nokuthintela ukuba iimpahla zonakale kwaye zilahleke ngexesha lokuthuthwa. Ezi zilandelayo ziimfuno ezisisiseko zokupakisha ukuthunyelwa kwesakhiwo sentsimbi:

1. Izinto zokupakisha: Izinto zokupakisha ezifanelekileyo mazisetyenziswe ekupakisheni. Kubandakanya umthi, iibhodi zomthi, iipleyiti zentsimbi, iibhokisi zentsimbi, iibhokisi zomthi, iipalethi zomthi, njl.njl., qinisekisa ukuba izinto zokupakisha zinamandla kwaye ziqinile ngokwaneleyo.

2. Ukubopha iipakethe: Ukupakisha kwezakhiwo zentsimbi kufuneka kuqiniswe kwaye komelele, ingakumbi izinto ezinkulu. Kufuneka kufakwe kwaye kuqiniswe kwiipalethi okanye kwizixhaso ukuthintela ukushukuma okanye ukushukuma ngexesha lokuthuthwa.

3. Ubuthambileyo: Inkangeleko yesakhiwo sentsimbi mayibe bushelelezi, kwaye akufuneki kubekho iikona okanye imiphetho ebukhali ukuze kuthintelwe ukonakalisa ezinye iimpahla okanye ukubeka ukhuseleko lomntu lwabasebenzi emngciphekweni.

4. Ayinakuba namanzi, ayibangeli ukungcangcazela, kwaye ayibangeli ukuguguleka: Izinto zokupakisha mazihambelane nemigaqo yokuthunyelwa kwaye zingabi namanzi, zingabangeli ukuguguleka, kwaye zingabangeli ukuguguleka. Ingakumbi ngexesha lokuthuthwa elwandle, kufuneka kunikwe ingqalelo kwiindlela zokuthintela ukuguguleka, ukususwa komswakama, iphepha elingabangeli ukufukama kunye nezinye iindlela zokuthintela isakhiwo sentsimbi ukuba singaguguleki, sibole, kwaye sibole ngamanzi olwandle.

AMANDLA ENKAMPANI

Yenziwe eTshayina, inkonzo yodidi oluphezulu, umgangatho ophezulu, idume kwihlabathi liphela

1. Isiphumo sesikali: Inkampani yethu inekhonkco elikhulu lokubonelela ngempahla kunye nomzi-mveliso omkhulu wentsimbi, ifikelela kwiziphumo zesikali kwezothutho kunye nokuthengwa kwempahla, kwaye iba yinkampani yentsimbi edibanisa imveliso kunye neenkonzo.

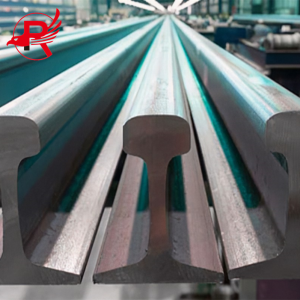

2. Ukwahluka kwemveliso: Ukwahluka kwemveliso, nayiphi na intsimbi oyifunayo ingathengwa kuthi, ikakhulu ibandakanya izakhiwo zentsimbi, iireyile zentsimbi, iipali zeshiti zentsimbi, izibiyeli ze-photovoltaic, intsimbi yetshaneli, iikhoyili zesinyithi zesilicon kunye nezinye iimveliso, nto leyo eyenza ukuba iguquguquke ngakumbi Khetha uhlobo lwemveliso oyifunayo ukuhlangabezana neemfuno ezahlukeneyo.

3. Ubonelelo oluzinzileyo: Ukuba nomgca wemveliso ozinzileyo kunye nochungechunge lobonelelo kunokubonelela ngobonelelo oluthembekileyo ngakumbi. Oku kubaluleke kakhulu kubathengi abafuna intsimbi eninzi.

4. Impembelelo yophawu: Banempembelelo ephezulu yophawu kunye nemarike enkulu

5. Inkonzo: Inkampani enkulu yentsimbi edibanisa ukwenziwa ngokwezifiso, uthutho kunye nemveliso

6. Ukhuphiswano lwamaxabiso: ixabiso elifanelekileyo

*Thumela i-imeyile ku[i-imeyile ikhuselwe]ukuze ufumane ikowuteshini yeeprojekthi zakho

UKUTYELELA KWABATHENGI