Iimveliso

-

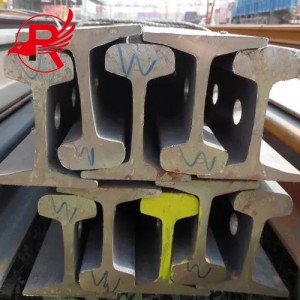

Isitimela Sentsimbi se-ISCOR Iireli Zentsimbi Iireli Ezikhanyayo Isitimela Semigodi Yamalahle Isitimela Semigodi

Isitimela seNsimbi se-ISCORzezona zinto ziphambili zemizila kaloliwe. Umsebenzi wayo kukuqondisa amavili esitokhwe esiqengqelekayo phambili, ukuthwala uxinzelelo olukhulu lwamavili, kwaye uludlulisele kwiindawo ezilalayo. Iireli kufuneka zibonelele ngomphezulu oqengqelekayo oqhubekayo, ogudileyo nongamelaniyo namavili. Kwizitimela ezisebenzisa umbane okanye iindawo ezizibloko ezizenzekelayo, iireli zinokusebenza njengeesekethe zemizila.

-

Isitimela seNsimbi se-ISCOR Isitimela seNsimbi Izibane zeNsimbi Imizila yeCrane Isitimela seNsimbi seLight_Rail

I-ISCOR Steel Rail zizinto ezibalulekileyo nezibalulekileyo ekwakhiweni nasekusebenzeni koololiwe. Zineempawu zokuba namandla okuthwala umthwalo, ukumelana nokuguguleka kunye nokumelana nokugqwala. Ngokuphucula ukusebenza kakuhle koololiwe, ukuqinisekisa ukhuseleko koololiwe, ukukhuthaza uphuhliso loqoqosho, ukonga izixhobo zamandla, njl.njl., zidlala indima ebalulekileyo kuphuhliso lwelizwe. Uphuhliso lubaluleke kakhulu kwisicwangciso-qhinga.

-

Isitimela sikaloliwe ISCOR Isitimela sentsimbi Isinyithi esinzima Isitimela esinzima

Ukusebenza kakuhle kwe-ISCOR Steel Rail: Ukusetyenziswa kwee-steel rails kunokunciphisa ukumelana nengxolo yoololiwe, kuphucule ukusebenza kakuhle koololiwe, kukhawulezise oololiwe, kunciphise ixesha lokuhamba, kwaye kuphucule umgangatho wenkonzo.

-

Isitimela sentsimbi se-ISCOR/Isitimela sentsimbi/Isitimela sesitimela/Isitimela esinobushushu

I-ISCOR Steel Rail inamandla aphezulu. Ngenxa yokuba yenziwe ngentsimbi enamandla aphezulu, ubunzima bayo buphezulu kakhulu (xa ithelekiswa neebha zentsimbi eziqhelekileyo), kwaye inokumelana noxinzelelo olukhulu kunye nemithwalo yempembelelo ngaphandle kokonakala; ikwanayo nokuqina okuhle: oko kukuthi, inamandla aphezulu okumelana neempembelelo eziphindaphindwayo. Ke ngoko, amathuba okuwa kwevili anokuncitshiswa kakhulu kwaye ukhuseleko lokuqhuba lunokuphuculwa.

-

Umenzi weSitimela seNsimbi se-ISCOR

Isitimela seNsimbi se-ISCORNjengesakhiwo sobunjineli esidibeneyo, umzila ubekwe ecaleni kwendlela, udlala indima ekhokelayo ekusebenzeni kololiwe, kwaye uthwala ngokuthe ngqo uxinzelelo olukhulu lwesitokhwe esiqengqelekayo kunye nomthwalo waso. Phantsi kwamandla okusebenza kololiwe, izinto ezahlukeneyo kufuneka zibe namandla aneleyo kunye nozinzo ukuqinisekisa ukuba uloliwe usebenza ngokukhuselekileyo, ngokutyibilikayo nangokungaphazanyiswa kwisantya esiphezulu esichaziweyo.

-

Uloliwe weSitimela seNsimbi se-ISCOR esikumgangatho ophezulu, uloliwe wesinyithi we-9kg, uloliwe wesinyithi we-9kg,

Ubude beereli ze-ISCOR Steel Rail kwilizwe lam yi-12.5m kunye ne-25m. Kwiireli ze-75kg/m, kukho ubude obunye kuphela be-25m. Kukwakho neereli ezimfutshane zemicu yangaphakathi yeegophe. Kwiireli ze-Huai ezisemgangathweni ze-12.5m, kukho iireli ezimfutshane ezintathu: 40mm, 80mm, kunye ne-120mm; kwiireli ze-25m, kukho iireli ezimfutshane ezintathu: 40mm, 80mm, kunye ne-160mm.

-

Umenzi weSitimela seNsimbi se-ISCOR

Iintlobo zeIsitimela seNsimbi se-ISCORzidla ngokwahlulwa ngobunzima. Umzekelo, i-50 rail esihlala sithi ibhekisa kwi-rail enobunzima obuyi-50kg/m, njalo njalo, kukho ii-rails ezingama-38, ii-rails ezingama-43, ii-rails ezingama-50, ii-rails ezingama-60, ii-rails ezingama-75, njl.njl. Kukwakho nee-track ezingama-24 kunye nee-track ezili-18, kodwa zonke ezo zii-almanacs ezindala. Phakathi kwazo, ii-rails ezine-rail ezingama-43 nangaphezulu zihlala zibizwa ngokuba zii-heavy rails.

-

Umzila Wesitimela Sensimbi ye-ISCOR Umzila Wesitimela Esinzima Wentsimbi Yendlela Eqhelekileyo Kaloliwe

Umsebenzi weISCOR Steel RaiI-l imele ukukhokela amavili esitokhwe esiqengqelekayo phambili, ithwale uxinzelelo olukhulu lwamavili, ize iludlulisele kwiindawo ezilalayo. Iireyile kufuneka zibonelele ngomphezulu oqengqelekayo oqhubekayo, ogudileyo nongamelaniyo namavili. Kwizitimela ezisebenzisa umbane okanye iindawo ezizibloko ezizenzekelayo, iireyile zinokuphinda zibe ziisekethe zendlela.

-

Umthengisi wesitimela seNsimbi se-ISCOR Umvelisi wesitimela seNsimbi

Isitimela seNsimbi se-ISCORinika amandla aphezulu kunye nokuqina. Ngenxa yokuba imizila kaloliwe kufuneka imelane nobunzima boololiwe kunye nefuthe lokubaleka, intsimbi yomzila kufuneka ibe namandla aneleyo kunye nokuqina.

-

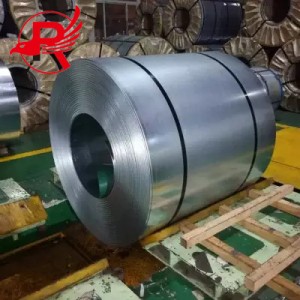

Iikhoyili/Iziqwenga zeSilikoni zeSteel eziQokelelweyo ze-GB eziQokelelweyo eziBandayo, ezikumgangatho olungileyo, ezilahlekileyo ngentsimbi ephantsi

Ngenxa yokumelana kwayo nokugqwala, ukuqina kwayo okuphezulu, kunye namandla ayo aphezulu, intsimbi yesilicon ikwasetyenziswa kakhulu ekuvelisweni kwezinto ezithile ezikhethekileyo kwiinqwelomoya, oomatshini, iimoto kunye nezinye iindawo.

Ngamafutshane, isinyithi se-silicon, njengohlobo lwepleyiti yesinyithi eqengqelekayo ebandayo eneempawu ezikhethekileyo, idlala indima ebalulekileyo kumacandelo emizi-mveliso kunye netekhnoloji, kwaye amacandelo okusetyenziswa kwayo asakhula. -

I-GB Standard DC06 B35ah300 B50A350 35W350 35W400 I-Cold Rolled Grain Oriented Non-Oriented Silicon Electrical Steel Coil

Iimfuno zokusebenza kwesinyithi se-silicon

1. Ukulahleka kwesinyithi okuphantsi, nto leyo ebaluleke kakhulu kumgangatho weeshiti zesinyithi zesilicon. Amazwe onke ahlela amanqanaba ngokwexabiso lokulahleka kwesinyithi. Okukhona ukulahleka kwesinyithi kuphantsi, kokukhona umgangatho uphezulu.

2. Ubunzulu bokufakelwa kwemagnethi (ukufakelwa kwemagnethi) buphezulu phantsi kwentsimi enamandla yemagnethi, nto leyo enciphisa umthamo kunye nobunzima bee-cores zeemoto kunye nee-transformers, nto leyo egcina amaphepha esinyithi e-silicon, iingcingo zobhedu, kunye nezinto zokukhusela. -

I-GB Standard Non-Oriented Electrical Silicon Steel Cold Rolled Silicon Steel Coil

Iimfuno zokusebenza kwentsimbi yesilicon zezi: ① Ukulahleka kwentsimbi okuphantsi, nto leyo ebonisa umgangatho weeshiti zentsimbi yesilicon. Amazwe onke ahlulahlula amanqanaba ngokwexabiso lokulahleka kwentsimbi. Okukhona ukulahleka kwentsimbi kuphantsi, kokukhona inqanaba liphezulu. ② Ubunzulu bokufakelwa kwemagnethi (ukufakelwa kwemagnethi) buphezulu phantsi kwentsimi enamandla yemagnethi, nto leyo enciphisa umthamo kunye nobunzima bee-cores zeemoto kunye nee-transformers, nto leyo egcina amaphepha entsimbi yesilicon, iingcingo zobhedu, kunye nezinto zokufaka ubushushu. ③Umphezulu uthambile, uthe tyaba kwaye ufana ngobukhulu, nto leyo enokuphucula i-filling factor ye-core. ④Iimpawu ezilungileyo zokubhoboza zibaluleke ngakumbi ekwenzeni iimoto ezincinci nezincinci. ⑤Ifilimu yokugquma umphezulu inokunamathela okuhle kunye nokudityaniswa, inokuthintela ukugqwala kwaye iphucule iipropati zokubhoboza.