Iimveliso

-

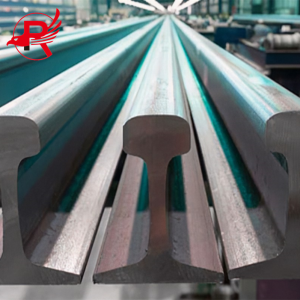

Iinxalenye zeSitimela samandla seCrane seNsimbi esiQokelelweyo esishushu esiQokelelweyo esinobunzima obuphezulu obuqhelekileyo

Isitimela sentsimbiyeyona nto iphambili kumzila kaloliwe. Umsebenzi wawo kukuqondisa amavili esitokhwe esiqengqelekayo phambili, ukumelana noxinzelelo olukhulu lwamavili, kunye nokudlulisela kwisixhobo sokulala. Umzila kufuneka unike umphezulu oqengqelekayo oqhubekayo, ogudileyo, kwaye onganyangekiyo kwivili. Kwicandelo lesitimela esinombane okanye kwicandelo leebhloko ezizenzekelayo, umzila ungasetyenziswa njengesekethe yomzila.

-

I-DIN 536 Crane Steel Rail A45 A55 A65 A75 A100 A120 A150 Standard Steel Rail Crane Rail

Izinto ezisetyenziswa kwireyile aziyozentsimbi eqhelekileyo, ngokubanzi zisebenzisa intsimbi yesakhiwo sekhabhoni ekumgangatho ophezulu kunye nentsimbi enamandla aphantsi, enamandla aphezulu, ukumelana nokuguguleka okuphezulu, ukuqina okuphezulu kunye nezinye iimpawu, yinkxaso ebalulekileyo ukuqinisekisa ukhuseleko kunye nokusebenza kakuhle kothutho lukaloliwe.

-

Uloliwe weSitimela seNsimbi esiQhelekileyo seDIN Uloliwe weSitimela seNsimbi esiQhelekileyo seCarbon

Iinkqubo zeendlela zikaloliwe beziyinxalenye ebalulekileyo yenkqubela phambili yoluntu ukususela ekuqaleni kwenkulungwane ye-19, ziguqula uthutho kunye norhwebo kwiindawo ezikude. Embindini wezi ndlela zibanzi kukho iqhawe elingadunyiswanga: iindlela zikaloliwe zentsimbi. Zidibanisa amandla, ukuqina, kunye nobunjineli obuchanekileyo, ezi ndlela zidlale indima ebalulekileyo ekubumbeni ihlabathi lethu lanamhlanje.

-

Isitimela se-DIN esiqhelekileyo seNsimbi esinzima seFektri Ixabiso eliPhezulu leeRails ezikumgangatho ophezulu zeTrack Metal Railway

I-DIN Standard Steel Rail yinxalenye ebalulekileyo yezothutho lukaloliwe ukuze ithwale ubunzima bukaloliwe, kwaye ikwayisiseko sololiwe. Yenziwe ngentsimbi enamandla kakhulu, inamandla kwaye iyamelana nokuguguleka, kwaye inokumelana noxinzelelo olukhulu kunye namandla okubetha.

-

Iinkonzo zokugoba ezisetyenziswa ziimoto ezisetyenziswa ziimoto ezisemgangathweni ze-GB Silicon Electrical Steel Coil ASTM Standard.

Iikhoyili zesinyithi zesilicon zisetyenziswa kakhulu kumashishini ahlukeneyo ngenxa yeempawu zazo ezintle zemagnethi. Nangona kunjalo, ezi khoyili ziza kwiindidi ezahlukeneyo, nganye ifanelekile kwizicelo ezithile. Ngokuqonda iimpawu kunye nokusetyenziswa kwazo, ungenza izigqibo ezinolwazi xa ukhetha ikhoyili yesinyithi yesilicon efanelekileyo kwiimfuno zakho ezithile.

-

I-GB Standard Silicon Lamination Steel Coil/Strip/Sheet, Relay Steel kunye neTransformer Steel

Iikhoyili zesinyithi zesilicon esizingca ngazo zine-magnetic conductivity ephezulu kakhulu kunye neempawu zokulahleka okuphantsi. Phakathi kwazo, ulawulo oluchanekileyo lomxholo wesilicon lwenza iphepha lesinyithi lesilicon libe namandla aphezulu okungenisa amandla kunye nokulahleka okuphantsi kombane we-eddy, ngaloo ndlela kunciphisa ukulahleka kwamandla ngexesha lokusebenza kwezixhobo, kwaye isiphumo sokonga amandla kunye nokunciphisa ukukhutshwa komoya siyamangalisa. Ukongeza, ikhoyili yesinyithi yesilicon ikwabonisa ukusebenza kakuhle kwe-punching shear kunye nokusebenza kwe-welding, okwenza ukucutshungulwa kube lula kwaye kusebenze kakuhle, kufezekisa kakhulu iimfuno zoshishino lwanamhlanje lwezixhobo ezisebenza kakuhle, ezonga amandla kunye nokukhusela okusingqongileyo.

-

I-50w600 50w800 50w1300 engajoliswanga kwaye ejoliswa kwingqolowa ebandayo eqengqelekayo ye-magnetic induction GB Ikhoyili yentsimbi yesilicon yombane eqhelekileyo

Ukulahleka kwentsimbi yesilicon (okubizwa ngokuba kukulahleka kwentsimbi) kunye namandla okungenisa amandla emagnethi (okubizwa ngokuba kukungeniswa kwamandla emagnethi) njengexabiso lesiqinisekiso semagnethi yemveliso. Ukulahleka okuphantsi kwentsimbi yesilicon kunokonga umbane omninzi, kwandise ixesha lokusebenza kweemoto kunye neetransformer kwaye kube lula inkqubo yokupholisa. Ukulahleka kwamandla okubangelwa kukonakala kwentsimbi yesilicon kubalelwa kwi-2.5% ~ 4.5% yokuveliswa kwamandla ngonyaka, apho ukulahleka kwentsimbi yetransformer kubalelwa kwi-50%, i-1 ~ 100kW encinci ibalelwa kwi-30%, kwaye i-ballast yesibane se-fluorescent ibalelwa kwi-15%.

-

Iziqwenga zentsimbi zombane ze-GB eziQokelelweyo eziBandayo ezisekelwe kwiSilicon Steel Crgo zeMagnetic Transformer Ei Iron Core

I-coil yesinyithi ye-silicon yinto ekhaphukhaphu, enomsindo ophantsi, esebenza kakuhle kakhulu eyenziwe ngepleyiti yesinyithi ye-silicon yombane. Ngenxa yokwakheka okukhethekileyo kunye netekhnoloji yokucubungula i-coil yesinyithi ye-silicon, inomoya ophezulu, ilahleko yesinyithi ephantsi kunye nobunzulu obuphantsi bokufakwa kwemagnethi, nto leyo eyenza ukuba isetyenziswe kakhulu kushishino lwamandla.

-

Amaxabiso e-GB Standard Cold Rolled Grain Oriented Crgo Electrical Silicon Steel Sheet Coil

Intsimbi yesilicon ibhekisa kwi-Fe-Si soft magnetic alloy, eyaziwa ngokuba yintsimbi yombane. Ipesenti yobunzima bentsimbi yesilicon Si yi-0.4% ~ 6.5%. Inamandla aphezulu okungena kwimagnethi, ixabiso eliphantsi lokulahleka kwentsimbi, iipropati ezintle zemagnethi, ilahleko ephantsi yomongo, amandla aphezulu okungenisa imagnethi, ukusebenza kakuhle kokubhoboza, umgangatho olungileyo womphezulu wepleyiti yentsimbi, kunye nokusebenza kakuhle kwefilimu yokugquma. Njl..

-

Iintlobo ngeentlobo zesakhiwo sentsimbi zinexabiso elikhethekileyo lokwakha

Isakhiwo sentsimbi Ukongeza, kukho inkqubo yesakhiwo sentsimbi yebhulorho engatshisi ubushushu. Isakhiwo ngokwaso asisebenzisi umbane kakuhle. Le teknoloji isebenzisa izihlanganisi ezikhethekileyo ezikrelekrele ukusombulula ingxaki yeebhulorho ezibandayo nezishushu kwisakhiwo. Isakhiwo esincinci se-truss sivumela iintambo kunye nemibhobho yamanzi ukuba idlule eludongeni ukuze kwakhiwe. Ukuhombisa kulula.

-

Ukuwelda Okuqhelekileyo Okuphezulu kwe-Q235H Isakhiwo seNsimbi yentsimbi Imisebenzi yoLwakhiwo lweCandelo leGalvanized Steel

Isakhiwo sentsimbisisakhiwo sobunjineli esakhiwe ngokucubungula, ukudibanisa nokufaka iipleyiti zentsimbi, intsimbi engqukuva, iipayipi zentsimbi, iintambo zentsimbi kunye neentlobo ngeentlobo zentsimbi. Izakhiwo zentsimbi kufuneka zinyamezele iziphumo ezahlukeneyo zendalo nezendalo ezenziwe ngumntu kwaye zizakhiwo zobunjineli kunye nezakhiwo ezinokuthembeka okwaneleyo kunye neenzuzo ezilungileyo kwezentlalo nakwezoqoqosho.

-

Uloliwe osemgangathweni weSitimela seNsimbi esiqhelekileyo i-DIN HMS / HMS 1 kunye ne-2, Iindlela zikaloliwe ezikwiSitimela esikhulu

Njengesakhiwo esixhasayo esiphambili kwiuloliweuthutho, amandla okuthwala imithwalo kaloliwe abaluleke kakhulu. Kwelinye icala, i-DIN Standard Steel Rail kufuneka imelane nobunzima kunye nefuthe likaloliwe, kwaye akulula ukuyiguqula nokuqhekeka; Kwelinye icala, phantsi kololiwe ohamba ngesantya esiphezulu, kuyimfuneko ukuqinisekisa uzinzo kunye nokuthembeka kukaloliwe. Ke ngoko, uphawu oluphambili lukaloliwe ngamandla aphezulu ukuqinisekisa ukhuseleko lukaloliwe.