Iimveliso

-

I-ASTM A29M yesakhiwo sentsimbi esithengiswa ngexabiso eliphantsi esisandula ukuveliswa, imiqadi yentsimbi eshushu eqengqelekayo, i-H beams

Intsimbi enobume obungu-Hsisixhobo sokwakha esiguquguqukayo esiye saguqula iindlela zokwakha zanamhlanje. Ukusetyenziswa kwayo ngokubanzi kwizicelo ezahlukeneyo, ukusuka kwizakhiwo eziphakamileyo ukuya kwiibhulorho, izakhiwo zoshishino ukuya kwiindawo zokufakela ezikude nolwandle, kuye kwabonakalisa amandla ayo angaqhelekanga, uzinzo, kunye nokuqina. Ukwamkelwa ngokubanzi kwentsimbi enomfanekiso we-H akuvumelekanga kuphela ekudalweni koyilo olumangalisayo lwezakhiwo kodwa kukwaqinisekisile ukhuseleko kunye nobude bexesha lezakhiwo kwiindawo ezahlukeneyo. Njengoko ubuchwepheshe buqhubeka buhambela phambili, kuyacaca ukuba intsimbi enomfanekiso we-H iya kuqhubeka nokuba phambili ekwakheni, ibumba ikamva elikhuselekileyo nelizinzileyo ngakumbi kushishino.

-

I-Hot Sale GB Standard Round Bar Carbon Steel Round Bar

Ibha ejikelezileyo ye-GB yintonga yesinyithi eyenziwe ngentsimbi yekhabhoni, i-iron-carbon alloy. Ifumaneka kwiindidi ngeendidi zeemilo kunye nobukhulu, njengengqukuva, isikwere, isicaba, kunye ne-hexagonal, iibha zentsimbi yekhabhoni zisetyenziswa kakhulu ekwakheni, kwimveliso, nakwimizi-mveliso. Ezi bha zinamandla aphezulu okutsalwa kwaye zaziwa ngokuqina kwazo kunye nokumelana nokugqwala, nto leyo eyenza ukuba zifaneleke kwiindidi ezahlukeneyo zezicelo zesakhiwo kunye nezoomatshini.

-

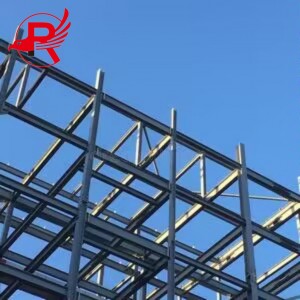

Naluphi na uhlobo lwesakhiwo sentsimbi sokwakha umgangatho omkhulu wokwakha

Iisakhiwo sentsimbi Inkqubo yecandelo lesinyithi ineenzuzo ezibanzi zobunzima obulula, ukwenziwa kwemveliso, ukufakwa ngokukhawuleza, umjikelo omfutshane wokwakha, ukusebenza kakuhle kwenyikima, ukubuyiselwa kotyalo-mali ngokukhawuleza, kunye nongcoliseko oluncinci lokusingqongileyo. Xa kuthelekiswa nezakhiwo zekhonkrithi eziqinisiweyo, ineenzuzo ezingaphezulu kwezona nkalo zintathu zophuhliso, kumhlaba jikelele, ngakumbi kumazwe aphuhlileyo nakwiindawo eziphuhlileyo, izixhobo zesinyithi zisetyenziswe ngokufanelekileyo nangokubanzi kwicandelo lobunjineli bokwakha.

-

Ulwakhiwo lwentsimbi Isakhiwo sentsimbi esingabizi kakhulu Indawo yokusebenzela Isakhiwo se-Prefab Factory Isakhiwo se-Warehouse

Iisakhiwo sentsimbiineenzuzo zokuba namandla aphezulu, ukuqina okuphezulu kunye nokusebenza okuphezulu, ukusebenza kakuhle kwemveliso kunye nokufakelwa, ukukwazi ukuphinda kusetyenziswe kunye nokukhuselwa kokusingqongileyo, ukuqina kunye nokumelana nokugqwala, ukusebenza kakuhle kwenyikima kunye nokumelana nomoya. Ezi mpawu zenza ukuba isakhiwo sentsimbi kubunjineli bokwakha banamhlanje sisetyenziswe kakhulu, kwaye sinamathuba abanzi ophuhliso.

-

Isitimela seNtsimbi esiqhelekileyo se-GB

Iireyili zentsimbiziinxalenye zendlela ezisetyenziswa kwiinkqubo zothutho lukaloliwe ezifana noololiwe, iinqanawa ezingaphantsi komhlaba, kunye neetram ukuxhasa nokukhokela izithuthi. Zenziwe ngohlobo olukhethekileyo lwentsimbi kwaye ziphantsi kwenkqubo ethile yokucubungula kunye nokulungisa. Iireli ziza kwiimodeli ezahlukeneyo kunye neenkcukacha, kwaye iimodeli kunye neenkcukacha ezifanelekileyo zinokukhethwa njengoko kufuneka ukuhlangabezana neemfuno zeenkqubo ezithile zothutho lukaloliwe.

-

Izakhiwo zeNsimbi ezilungisiweyo Izakhiwo zeFektri Intengiso ethe ngqo Yenziwe ngeNtsimbi yeSakhiwo Ipe 300 HI Beams

Iisakhiwo sentsimbiIzinto eziluhlaza zinamandla aphezulu okutsalwa, ubunzima bazo obupheleleyo bulula, amandla ebholiti aphezulu, kwaye isixhobo sokurhawuzelela esithambileyo naso siphezulu kakhulu. Xa kuthelekiswa nekhonkrithi kunye nomthi, umlinganiselo woxinano kunye namandla okucinezela uphantsi kakhulu, ngoko ke phantsi kweemeko ezifanayo zomthamo wokuthwala, isakhiwo sentsimbi sinecandelo elincinci, kwaye ubunzima baso bulula, obulungele ukuthuthwa kunye nokufakelwa, bufanelekile kwisithuba esikhulu, ukuphakama okuphezulu, kunye nesakhiwo sokuthwala esinzima *Kuxhomekeke kwisicelo sakho, sinokuyila inkqubo yesakhelo sesinyithi engabizi kakhulu kwaye ihlala ixesha elide ukukunceda wenze ixabiso eliphezulu kwiprojekthi yakho.

-

Isitimela sikaloliwe sentsimbi eqhelekileyo se-GB singasetyenziselwa ukwakha ezinkulu

Iireyili zentsimbiziinxalenye zendlela ezisetyenziswa kwiinkqubo zothutho lukaloliwe ezifana noololiwe, iinqanawa ezingaphantsi komhlaba, kunye neetram ukuxhasa nokukhokela izithuthi. Zenziwe ngohlobo olukhethekileyo lwentsimbi kwaye ziphantsi kwenkqubo ethile yokucubungula kunye nokulungisa. Iireli ziza kwiimodeli ezahlukeneyo kunye neenkcukacha, kwaye iimodeli kunye neenkcukacha ezifanelekileyo zinokukhethwa njengoko kufuneka ukuhlangabezana neemfuno zeenkqubo ezithile zothutho lukaloliwe.

-

Isakhiwo seNsimbi esingabizi kakhulu Indawo yokusebenzela / iWarehouse / iFactory Building Isakhiwo seWarehouse seNsimbi

Isakhiwo sentsimbiubunjineli buneengenelo zokuba namandla aphezulu, ukukhaphukhaphu, isantya sokwakha esikhawulezayo, ukuphindeka kwakhona, ukhuseleko kunye nokuthembeka, kunye noyilo oluguquguqukayo. Ke ngoko, isetyenziswa kakhulu kwizakhiwo, iibhulorho, iinqaba kunye nezinye iindawo. Ngophuhliso oluqhubekayo kunye nokuphuculwa kwetekhnoloji yobunjineli besakhiwo sentsimbi, kukholelwa ukuba ubunjineli besakhiwo sentsimbi buya kudlala indima ebaluleke ngakumbi kwicandelo lokwakha elizayo.

-

Umgangatho ophezulu h16 x 101 150x150x7x10 Q235 Q345b I-Hot Rolled IPE HEA HEB EN Intsimbi Emile okwe-H

I-HEA, i-HEB, kunye ne-HEM ziimpawu zamacandelo e-IPE (I-beam) aseYurophu asemgangathweni.

-

I-European Standard EN Ipe 80 Beam I Beam Ipn Beam 100 Mm 20mm S235jr A36 S275jr Ss400 I Beam

IUmqadi we-IPN, eyaziwa ngokuba yi-IPE beam, luhlobo lwe-I-beam esemgangathweni yaseYurophu ene-cross-section eyilwe ngokukodwa equka ii-flanges ezihambelanayo kunye ne-slope kwiindawo ze-flange zangaphakathi. Ezi beam zisetyenziswa rhoqo kubunjineli bokwakha kunye nolwakhiwo ngenxa yamandla azo kunye nokuguquguquka kwazo ekuxhaseni izakhiwo ezahlukeneyo ezifana nezakhiwo, iibhulorho, kunye nezakhiwo zoshishino. Zaziwa ngomthamo wazo ophezulu wokuthwala imithwalo kwaye zisetyenziswa kakhulu kwiindlela ezahlukeneyo zokusebenza ngenxa yokusebenza kwazo okuthembekileyo.

-

I-ASTM A36 Angle Bar Low Carbon Steel

Intsimbi ye-ASTM Elinganayo ye-Angleeyaziwa kakhulu ngokuba yi-engile iron, yintsimbi ende enamacala amabini angqameneyo. Kukho i-engile iron elinganayo kunye ne-engile iron engalinganiyo. Ububanzi bamacala amabini e-engile iron elinganayo bulingana. Inkcazo ichazwa nge-mm yobubanzi becala × ububanzi becala × ubukhulu becala. Njenge-“∟ 30 × 30 × 3″, oko kukuthi, i-engile iron elinganayo enobubanzi becala obuyi-30mm kunye nobukhulu becala obuyi-3mm. Ingabonakaliswa nangumodeli. Imodeli yisentimitha yobubanzi becala, njenge-∟ 3 × 3. Imodeli ayimeli ubukhulu bomphetho owahlukileyo kwimodeli efanayo, ngoko ububanzi bomphetho kunye nobukhulu bomphetho bentsimbi ye-engile kufuneka izaliswe ngokupheleleyo kwisivumelwano nakwamanye amaxwebhu ukuze kuthintelwe ukusebenzisa imodeli yodwa. Inkcazo yentsimbi ye-engile elinganayo egoqwe ngobushushu yi-2 × 3-20 × 3.

-

Intsimbi Enemilo Efana ne-H ye-EN Heb kunye ne-Hea Beam eWelded H Steel

EI-NHIntsimbi Enemilo ziimpawu zecandelo le-IPE (I-beam) yaseYurophu esemgangathweni.