Ukucutshungulwa kwesinyithi kunye nokwenza ngokwezifiso

-

Izinyuko zeSpiral zangaphandle zeZinyuko zanamhlanje zoyilo lweSteel Metal Izinyuko zangaphandle

Izitebhisi ezijikelezayo zangaphandle zanamhlanje ziluhlobo lwezitebhisi ezigcina indawo, zanamhlanje nezisebenzayo ezijikeleza phezulu zijikeleze ikholamu ephakathi. Zingasetyenziswa kwiithala, kwiidekhi, kwiibhalkhoni, kwiigadi, okanye njengekhonkco langaphandle phakathi kweendawo ezikwimigangatho eyahlukeneyo.

-

Ulwakhiwo lweNsimbi yesakhiwo se-ASTM Standard Welded H-Beam Parts for Construction & Steel Structures

Iinxalenye ze-H-Beam ziimveliso zentsimbi ye-H-beam ezicutshungulwa ngokusika, ukuwelda, ukubhola, unyango lomphezulu njalo njalo. Zisetyenziswa kakhulu kwisakhiwo sentsimbi, kwimizi-mveliso, kwindawo yokusebenzela, kwindawo yokugcina impahla, kwibhulorho nakwiziseko zophuhliso ezinemithwalo ephezulu kunye nozinzo kwisakhiwo.

-

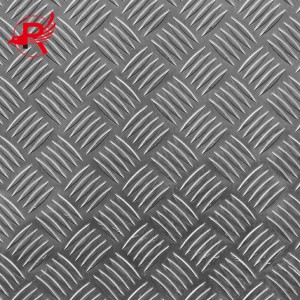

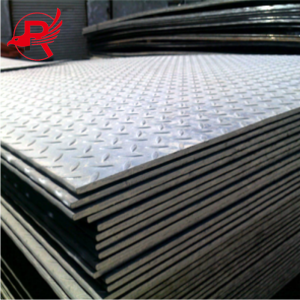

I-ASTM A36 1008 4320 SS400 S235JR Ipleyiti Eyiliweyo Eshushu Eqengqelekayo Yentsimbi Yekhabhoni Ye-MS Enezikere/Iphepha Ledayimani

Iipleyiti zentsimbi eziqinileyo nezinemiqolomba ephakanyisiweyo ukuze zibambeke kakuhle—zilungele umgangatho okhuselekileyo wemizi-mveliso, iindlela zokuhamba, kunye nezinyuko.

-

I-Hot Selling High Quality Export Oriented Diamond Pattern Anti-Slip Galvanized Checkered Steel Plate For Floor

Iipleyiti zentsimbi eziqinileyo ezineepatheni ezingatyibilikiyo—zifanelekile kakhulu kwimigangatho yemizi-mveliso ekhuselekileyo, iindlela zokuhamba, kunye nezinyuko.

-

Ipleyiti yentsimbi yekhabhoni ye-Astm A36 A252 Ipleyiti yentsimbi enomphetho ye-Q235

Intsimbi yepleyiti yedayimani luhlobo lweshiti yentsimbi enedayimani ephakanyisiweyo okanye ipateni ethe tyaba kumphezulu wayo, eyenzelwe ukomeleza ukubamba nokubambelela. Isetyenziswa kakhulu kwimigangatho yemizi-mveliso, iindlela zokuhamba, izinyuko, kunye nezinye izinto apho ukumelana nokutyibilika kubalulekile. Ezi pleyiti zentsimbi zifumaneka ngobukhulu obahlukeneyo, zinokwenziwa ngentsimbi yekhabhoni, intsimbi engatyiwayo, okanye ezinye izinyithi, zibonelela ngokuguquguquka nokuqina kwiindawo ezahlukeneyo zoshishino nezorhwebo.

-

Ipleyiti yentsimbi yekhabhoni ekumgangatho ophezulu yefektri ethengiswayo enezithende ezishushu eziqengqelekayo ipleyiti yentsimbi yekhabhoni i-S235 S275 S355 yokwakhiwa

Iipleyiti zentsimbi ezineetsheki, ezaziwa ngokuba ziipleyiti zentsimbi ezineepateni okanye iipleyiti zentsimbi ezingatyibilikiyo, ziisheyiti zentsimbi ezinepateni ephakanyisiweyo kumphezulu wazo. Iipateni eziqhelekileyo ziquka iimilo zedayimani, ezizinxantathu, nezingqukuva. Ezi pateni aziphuculi nje kuphela iipropati ezingatyibilikiyo zepleyiti yentsimbi, kodwa zikwabonelela ngobuhle obuhle kunye namandla anyukileyo. Ezi pleyiti zentsimbi zisetyenziswa kakhulu kumaqonga emizi-mveliso, kwiindawo zokunyathela izitebhisi, kwiindlela zokuhamba, kwiimigangatho yezithuthi, kwiimigangatho yokugcina impahla, nakwezinye iindawo, zibonelela ngokhuseleko kunye nokuqina.

-

Ipleyiti yesinyithi eyenziwe ngetshekhi yentsimbi yekhabhoni eyi-4 mm yesinyithi esenziwe ngekhabhoni yezixhobo zokwakha

Iipleyiti zentsimbi ezinemibala eqaqambileyo, ezaziwa ngokuba ziipleyiti zentsimbi ezineepateni okanye iipleyiti zentsimbi ezingatyibilikiyo, ziipleyiti zentsimbi ezinepateni eqhelekileyo yeenduli eziphakanyisiweyo kumphezulu wazo. Iipateni eziqhelekileyo ziquka iimilo zedayimani, ezimbhoxo, nezingqukuva. Olu lwakhiwo lomphezulu olukhethekileyo alupheleli nje ekukhuliseni ukungqubana kwaye luthintele ukutyibilika, kodwa lukwabonelela ngobuhle obuthile.

-

Ukwakhiwa kwesakhiwo seepleyiti ezineetshetshe ze-ASTM A36 Q235B Q345B S235JR S355JR Iipleyiti zentsimbi eziqengqelekayo ezishushu

Iipleyiti zentsimbi ezichekishwe ngetshekhi, ezaziwa ngokuba ziipleyiti zedayimani okanye iipleyiti zokunyathela, ziimveliso zentsimbi ezikhethekileyo eziyilwe ngeepateni zomphezulu ophakanyisiweyo—ngokuyintloko iimilo zedayimani okanye ezithe tye—ezenziwe ngokuqengqeleka okushushu, ukunyathela okubandayo, okanye ukuhombisa. Inzuzo yazo ephambili ikukusebenza okungatyibilikiyo kwezi texture ziphakanyisiweyo: ngokwandisa ukungqubana komphezulu, zinciphisa ngempumelelo umngcipheko wokutyibilika nokuba zimanzi, zinamafutha, okanye zinothuli, nto leyo ezenza zibe lukhetho olugxile kukhuseleko kwiimeko zezithuthi ezininzi okanye ezinzima.

-

Inkonzo yeemveliso zehardware ezisetyenziswa ngokwezifiso ze-Oem Ukwenziwa kwesinyithi sephepha lesinyithi sentsimbi

Izixhobo zentsimbi ezicutshungulwayo, ezaziwa ngokuba zizixhobo zentsimbi ezenziweyo, zibhekisa kwizixhobo okanye iimveliso ezigqityiweyo ezenziwe ngezinto zentsimbi (ezifana neepleyiti zentsimbi, iipayipi, kunye nemilo yesakhiwo) ngeenkqubo ezifana nokusika, ukunyathela, ukugoba, ukuwelda, ukwenza i-machining, unyango lobushushu, kunye nokugqiba umphezulu, ukuhlangabezana nemilo ethile, ubungakanani, kunye neemfuno zokusebenza. Zihlala zisetyenziswa njengezixhobo ezibalulekileyo zezixhobo, oomatshini, okanye izakhiwo zobunjineli.

-

Umatshini wokusika i-laser die umatshini wokusika i-fiber laser ishiti yesinyithi

isinyithi esisikiweyo nge-laseryindlela yokucubungula ukusika echanekileyo kakhulu nesebenza kakuhle kakhulu esetyenziswa kakhulu ekucubunguleni izinyithi, iiplastiki, iinkuni nezinye izinto. Ukusika nge-laser kusebenzisa umqadi we-laser onamandla aphezulu ukunyibilikisa okanye ukufutha izinto, okuvumela ukusika okukhawulezayo nokuchanekileyo. Le ndlela yokucubungula ineempawu ezilandelayo:

Okokuqala, ukusika nge-laser kunobunono obuphezulu kakhulu kunye nobukhulu obuphezulu, okuvumela ukusika nokukrola izinto ezincinci, kwaye kufanelekile ukwenza iindawo ezineemilo ezintsonkothileyo kunye nezakhiwo ezichanekileyo.

Okwesibini, ukusika nge-laser kuyakhawuleza kwaye kusebenza kakuhle kakhulu. Izixhobo zokusika nge-laser zinokuhamba kwaye zisike ngokukhawuleza, nto leyo eyenza ukuba zilungele imveliso ephezulu kunye nokusebenza kakuhle.

Ukongeza, ukusika nge-laser akunampembelelo ingako kwizinto kwaye indawo echaphazeleka bubushushu incinci. Xa kuthelekiswa neendlela zemveli zokusika, ukusika nge-laser kunokunciphisa ukuguquguquka kunye nemiphumo yobushushu kwaye kugcine iimpawu zokuqala zezinto.

Ukusika nge-laser kulungele izinto ezahlukeneyo, kuquka iintsimbi, iiplastiki, iglasi, iiseramikhi, njl.njl., kwaye ke ngoko kusetyenziswa kakhulu kwi-aerospace, kwimveliso yeemoto, kwizixhobo ze-elektroniki nakwamanye amashishini.

Ngamafutshane, ukusika nge-laser, njengendlela yokucubungula ukusika ngokuchanekileyo nangokufanelekileyo, kubonelela ngezisombululo zokucubungula ngokuchanekileyo kuzo zonke iinkalo zobomi kwaye kube yenye yeenkqubo ezibalulekileyo nezibalulekileyo kwimveliso yanamhlanje.

-

Inkonzo yokuWelda yeSinyithi yeNsimbi eyenziwe ngokwezifiso kunye neNkonzo yokuSika iLaser Ukunyathela iinxalenye zeSheet Metal Processing

Ukuwelda yinkqubo eqhelekileyo yokuvelisa esetyenziselwa ukudibanisa izinto zesinyithi okanye zeplastiki ngokuzinyibilikisa, ukuziqinisa okanye ukuzicinezela. Iinkqubo zokuwelda zihlala zisetyenziswa ekwenzeni iindawo zesakhiwo, imibhobho, iinqanawa kunye nezinye iimveliso, kunye nomsebenzi wokulungisa nokugcina izinto zisemgangathweni.

-

Ukusika iWaterjet engarhabaxayo OEM Custom Precision Metal Cutting Parts Carbon Steel Stainless Steel 3/4/5 Axis CNC Machining

Ukusika iWaterjet bubuchwepheshe obuphambili bokusika okubandayo obusebenzisa umjelo wamanzi oxinzelelo oluphezulu (odla ngokucinezelwa ukuya kwi-30,000–90,000 psi) — odla ngokuxutywa namasuntswana arhabaxa afana negarnet kwizinto eziqinileyo — ukusika ngokuchanekileyo, ukubumba, okanye ukukrola uluhlu olubanzi lwezinto zokusebenza. Njengenkqubo ebandayo, ithintela ukugqwetheka kobushushu, ukuqina kwezinto, okanye utshintsho lweekhemikhali kwizinto ezisikiweyo, okwenza ukuba zilungele ukusetyenziswa okunobushushu okanye okuchanekileyo. Ibonisa ukuguquguquka okukhulu, ikwazi ukuphatha izinto ezifana nesinyithi (intsimbi, i-aluminium, i-titanium), ilitye, iglasi, iiseramikhi, izinto ezidityanisiweyo, kwanokutya, kunye nokukwazi ukusika iimilo ezintsonkothileyo (umz., iipateni ezintsonkothileyo, imiphetho egobileyo) kunye nezinto zokusebenza ezixineneyo (ukuya kuthi ga kwishumi leesentimitha) ngelixa igcina imiphetho egudileyo kunye nokuchaneka okuphezulu. Isetyenziswa kakhulu kumashishini aquka i-aerospace (kwizinto zesinyithi ezichanekileyo), iimoto (kwizinto ezenziwe ngokwezifiso), uyilo (lwezinto zokuhombisa ngamatye/iglasi), kunye nokuvelisa (kwizinto ezidityanisiweyo), ukusika i-waterjet kukwahlukile ngobuhlobo bayo nokusingqongileyo - ayivelisi msi unobungozi okanye inkunkuma eninzi, ihambelana neemfuno zemveliso eluhlaza yanamhlanje.