I-ASTM Equal Angle Steel Galvanized Equal L Shape Angle Bar yezixhobo zokwakha

Iinkcukacha zeMveliso

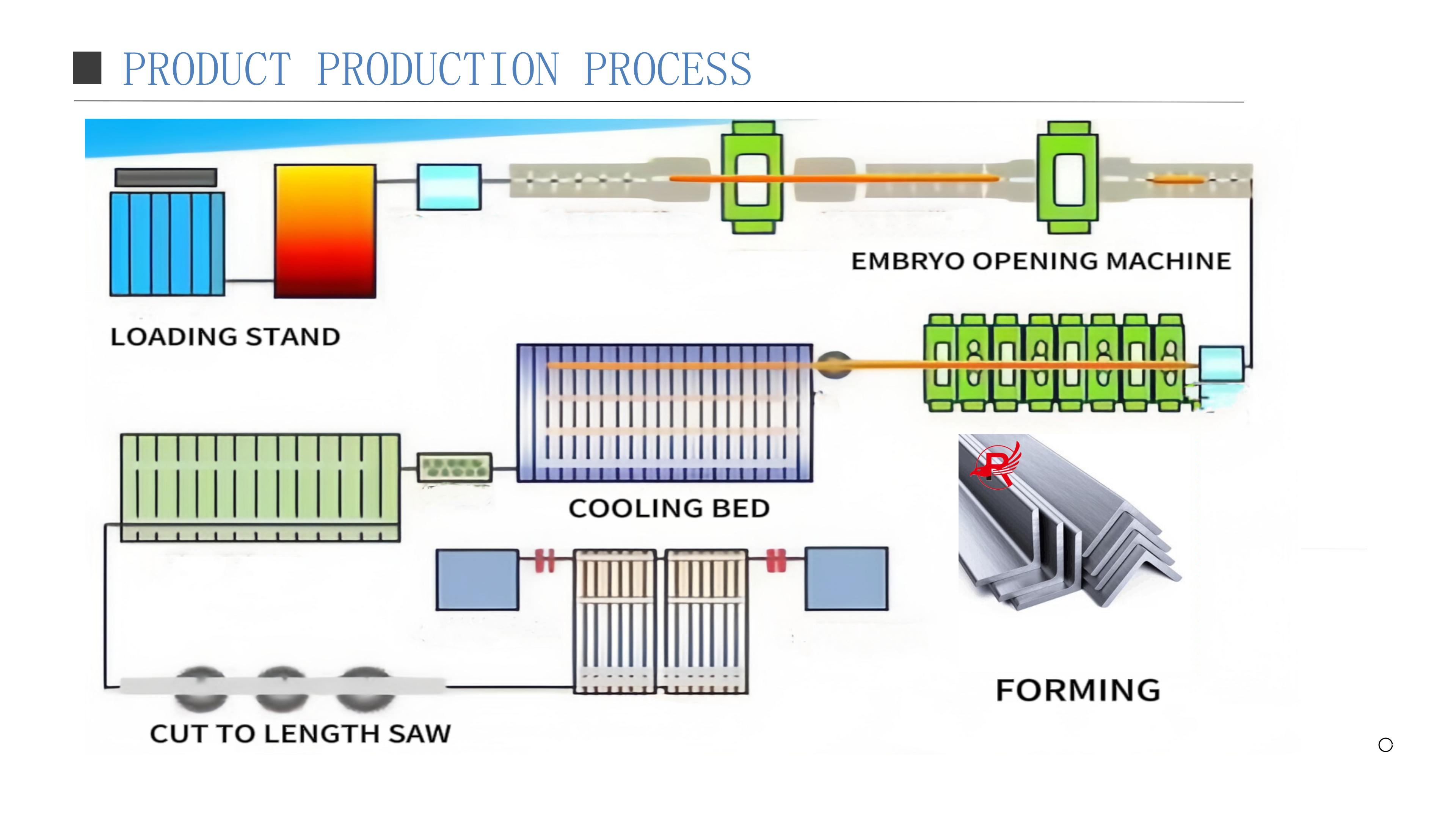

Inkqubo yemvelisointsimbi ye-engile ye-galvanizedidla ngokubandakanya la manyathelo aphambili alandelayo:

Ukulungiswa kwezinto eziluhlaza: Okokuqala, kufuneka kulungiswe izinto eziluhlaza zentsimbi ekwi-engile esemgangathweni ophezulu, ngokuqhelekileyo intsimbi yesakhiwo sekhabhoni okanye intsimbi e-alloy ephantsi njengezinto eziluhlaza.

Ukucubungula kunye nokwenziwa: Ukusika, ukugoba, ukugoba okubandayo okanye ukuqengqa intsimbi ye-engile eluhlaza ibe yimo kunye nobukhulu bentsimbi ye-engile efunekayo.

Unyango lomphezulu: Unyango lomphezulu lwenziwa kwintsimbi ye-engile eyenziweyo, kubandakanya ukususa umhlwa, ukucoca kunye nokucola ukuqinisekisa ukuba umphezulu ucocekile kwaye ugudile.

Unyango lokufudumeza: Ukufudumeza intsimbi ye-engile ukuphucula amandla okubopha phakathi komaleko we-galvanized kunye ne-matrix yentsimbi.

I-hot-dip galvanizing: I-angle steel elungisiweyo kwangaphambili ifakwa kulwelo lwe-zinc olunyibilikisiweyo ukuze lugqume umphezulu ngomaleko we-zinc ukwenza i-angle steel ehlanganisiweyo. I-hot-dip galvanizing yeyona nkqubo isetyenziswa kakhulu kwi-galvanizing, eqinisekisa ukubopha okuqinileyo phakathi komaleko we-zinc kunye ne-matrix yentsimbi.

Ukupholisa nokugqiba: Intsimbi ye-angle ye-galvanized iyapholiswa, ihlulwe kwaye ihlolwe ukuqinisekisa umgangatho kunye nembonakalo yemveliso.

Ukupakisha ngaphambi kokuba uphume efektri: Ukupakisha intsimbi ye-angle ye-galvanized, kuquka ukusebenzisa ifilimu yeplastiki, iipallet zomthi kunye nezinye izinto ukuze kube lula ukuthuthwa nokugcinwa.

Oku kungentla yinkqubo yokuvelisa ngokubanzi intsimbi ye-galvanized angle, apho inyathelo ngalinye lifuna ulawulo oluqinileyo kunye nokusebenza ukuqinisekisa umgangatho wemveliso kunye nokusebenza kakuhle kwemveliso.

Intsimbi ye-ASTM Elinganayo ye-Angle

Ibanga: A36、A709、A572

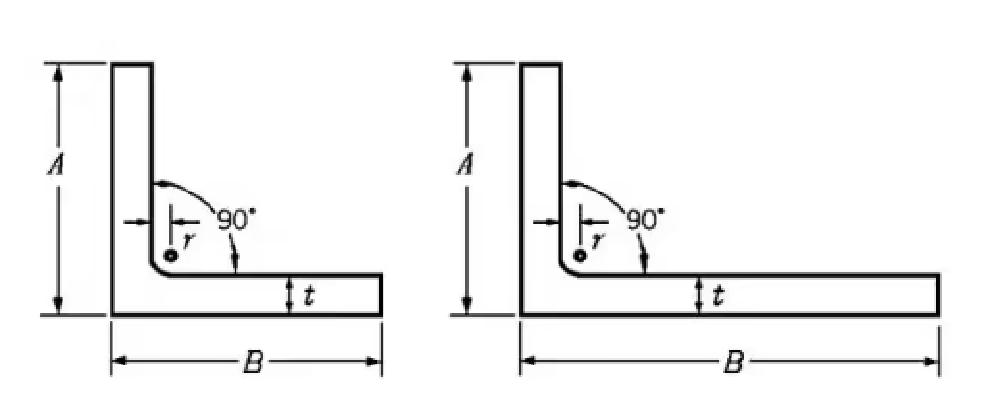

Ubungakanani: 20x20mm-250x250mm

Umgangatho:I-ASTM A36/A6M-14

| Zonke iimveliso ezichaziweyo zingenziwa ngokwezifiso ngokweemfuno zabathengi | |

| Igama lemveliso | Yenzelwe eTshayina Ms s235jr a36 angle bar |

| Umgangatho | I-ASTM, i-JIS, i-DIN EN, i-GB |

| Ibanga lezinto | 20#,45#,Q195,Q215,Q235B,Q345B, S235JR/S235/S355JR/S355/SS440/SM400A/SM400B |

| Ubukhulu | 1.5mm-25mmokanye ngokwesicelo somthengi |

| Ububanzi | 37mm-88mm okanye ngokwesicelo somthengi |

| Ubude | 1000mm-12000mm okanye ngokwesicelo somthengi |

| Ubuchule | Iqengqiwe ngobushushu/Iqengqiwe ngobushushu obubandayo |

| Unyango lomphezulu | Mnyama, Igqunyiwe ngesinyithi, igqunyiwe, ipeyintiwe okanye ngokwesicelo sakho |

| Immimiselo yokuhlawula | T/T, |

| Ixesha lokuzisa | Ngokwesiqhelo zingaphakathi kweentsuku ezisi-7, ixesha libekwa ngokwenani labathengi |

| Ukupakisha | 1. I-OD enkulu: ngobuninzi 2. I-OD encinci: ipakishwe yimicu yentsimbi 3. Ilaphu elukiweyo elineziqwenga ezisi-7, Okanye iphakheji yokuthumela ngaphandle eqhelekileyo okanye njengoko kufuneka. |

| Isatifikethi | Uvavanyo lwe-ISO, SGS, CE okanye olunye uhlobo lovavanyo oluyamkelekileyo. |

| Inzuzo | I-MOQ encinci + Umgangatho ophezulu + Ixabiso elikhuphisanayo + Ukuhanjiswa okukhawulezayo |

| Isicelo | Ushishino, uLwakhiwo, uHlobo, uLwakhiwo lweenqanawa, iiBridge, iChassis yeemoto, njl. |

UBUKHULU BEMVELISO

| Intsimbi elinganayo ye-engile | |||||||

| Ubungakanani | Ubunzima | Ubungakanani | Ubunzima | Ubungakanani | Ubunzima | Ubungakanani | Ubunzima |

| (MM) | (KG/M) | (MM) | (KG/M) | (MM) | (KG/M) | (MM) | (KG/M) |

| 20*3 | 0.889 | 56*3 | 2.648 | 80*7 | 8.525 | 12*10 | 19.133 |

| 20*4 | 1.145 | 56*4 | 3.489 | 80*8 | 9.658 | 125*12 | 22.696 |

| 25*3 | 1.124 | 56*5 | 4.337 | 80*10 | 11.874 | 12*14 | 26.193 |

| 25*4 | 1.459 | 56*6 | 5.168 | 90*6 | 8.35 | 140*10 | 21.488 |

| 30*3 | 1.373 | 63*4 | 3.907 | 90*7 | 9.656 | 140*12 | 25.522 |

| 30*4 | 1.786 | 63*5 | 4.822 | 90*8 | 10.946 | 140*14 | 29.49 |

| 36*3 | 1.656 | 63*6 | 5.721 | 90*10 | 13.476 | 140*16 | 33.393 |

| 36*4 | 2.163 | 63*8 | 7.469 | 90*12 | 15.94 | 160*10 | 24.729 |

| 36*5 | 2.654 | 63*10 | 9.151 | 100*6 | 9.366 | 160*12 | 29.391 |

| 40*2.5 | 2.306 | 70*4 | 4.372 | 100*7 | 10.83 | 160*14 | 33.987 |

| 40*3 | 1.852 | 70*5 | 5.697 | 100*8 | 12.276 | 160*16 | 38.518 |

| 40*4 | 2.422 | 70*6 | 6.406 | 100*10 | 15.12 | 180*12 | 33.159 |

| 40*5 | 2.976 | 70*7 | 7.398 | 100*12 | 17.898 | 180*14 | 38.383 |

| 45*3 | 2.088 | 70*8 | 8.373 | 100*14 | 20.611 | 180*16 | 43.542 |

| 45*4 | 2.736 | 75*5 | 5.818 | 100*16 | 23.257 | 180*18 | 48.634 |

| 45*5 | 3.369 | 75*6 | 6.905 | 110*7 | 11.928 | 200*14 | 42.894 |

| 45*6 | 3.985 | 75*7 | 7.976 | 110*8 | 13.532 | 200*16 | 48.68 |

| 50*3 | 2.332 | 75*8 | 9.03 | 110*10 | 16.69 | 200*18 | 54.401 |

| 50*4 | 3.059 | 75*10 | 11.089 | 110*12 | 19.782 | 200*20 | 60.056 |

| 50*5 | 3.77 | 80*5 | 6.211 | 110*14 | 22.809 | 200*24 | 71.168 |

| 50*6 | 4.456 | 80*6 | 7.376 | 125*8 | 15.504 | ||

Iimbonakalo

intsimbi ye-engileineempawu ezilandelayo:

Ukumelana nokugqwala: Umphezulu wentsimbi ye-galvanized angle ugqunywe ngumaleko we-zinc, onokuthintela ngempumelelo ioksijini, amanzi kunye nezinye izinto zeekhemikhali ekungcoleni intsimbi kwaye wandise ubomi benkonzo yentsimbi ye-angle.

Umphezulu ogudileyo: Umphezulu wentsimbi egobileyo ekhazimlayo uthambile kwaye ulungelelene, kwaye inkangeleko intle. Ifanelekile kwiimeko ezineemfuno eziphezulu zenkangeleko.

Kulula ukuyicubungula: Intsimbi ye-engile ye-galvanized isebenza kakuhle ekucubunguleni kwaye inokusikwa, idityaniswe, igotywe, njl.njl., kwaye ifanelekile kwiindlela ezahlukeneyo zokucubungula kunye nokwenza.

Ukhuseleko lokusingqongileyo: Inkqubo yokugaya i-hot-dip isetyenziswa kwinkqubo yokuvelisa intsimbi ye-galvanized angle, engavelisi zinto zinobungozi kwaye ihambelana neemfuno zokhuseleko lokusingqongileyo.

Ixabiso eliphantsi: Ixabiso lentsimbi egobileyo ye-galvanized angle liphantsi kakhulu, lisebenza kakuhle ngexabiso, kwaye lifanelekile kwiiprojekthi ezahlukeneyo zoqoqosho kunye nokuveliswa kweemveliso.

Iinjongo ezininzi: Intsimbi ye-engile ye-galvanized isetyenziswa kakhulu ekwakheni, ekuveliseni oomatshini, kwizixhobo zamandla, kwizixhobo zonxibelelwano nakwezinye iindawo, kwaye inokuguquguquka okukhulu nokusebenza.

Ngokubanzi, intsimbi ye-galvanized angle ineempawu zokumelana nokugqwala, umphezulu ogudileyo, ukucutshungulwa okulula, ukhuseleko lokusingqongileyo, ukonga, kunye neenjongo ezininzi. Yinto yesinyithi esetyenziswa rhoqo kwaye ifanelekile kwiinkalo ezahlukeneyo zobunjineli kunye nemveliso.

Isicelo

Ngenxa yokumelana kwayo nokugqwala, amandla aphezulu, kunye nokulula ukuyilungisa, intsimbi ye-galvanized angle isetyenziswa kakhulu kwiindawo ezahlukeneyo, kuquka kodwa kungaphelelanga apho kwezi ndawo zilandelayo:

Ubunjineli bokwakha: busetyenziselwa izixhaso, izakhelo, imiqadi kunye neekholamu zezakhiwo zokwakha, kunye nee-handrails zezitebhisi, ii-railings, njl.njl.

Ubunjineli beendlela neebhulorho: busetyenziselwa ukhuseleko lwendlela, izakhiwo ezixhasa iibhulorho, njl.njl.

Izixhobo zamandla: ezisetyenziswa kwiinqaba zamandla, iinkxaso zemigca yothumelo, njl.

Ukwenziwa koomatshini: izakhiwo zenkxaso, iifreyimu, njl.njl. zezixhobo zoomatshini.

Uthutho: Izixhobo zokwakha iinqanawa, izithuthi zikaloliwe, iimoto kunye nezinye iindlela zothutho.

Izakhiwo zezolimo: ezisetyenziswa kwiindawo zokugcina izityalo zezolimo, kwiingcingo zemfuyo, njl.

Ukwenziwa kwefenitshala: iindawo zesakhiwo, izixhaso, njl. zefenitshala.

Isakhiwo seSitayile: Izinto ezisetyenziswa kwizakhiwo zesakhiwo sentsimbi.

Ngokubanzi, intsimbi ye-galvanized angle isetyenziswa kakhulu ekwakheni, ekuveliseni oomatshini, kwizixhobo zamandla, kwezothutho nakwezinye iindawo. Yintsimbi esebenza ngeendlela ezininzi.

UKUPAKISHA NOKUTHUMELA

Intsimbi ye-engile ipakishwa ngokufanelekileyo ngokobukhulu bayo kunye nobunzima bayo ngexesha lokuthuthwa. Iindlela zokupakisha eziqhelekileyo ziquka:

Isisongelo: Intsimbi encinci ye-Angle idla ngokusongwa ngentsimbi okanye ngeteyiphu yeplastiki ukuqinisekisa ukhuseleko kunye nozinzo lwemveliso ngexesha lokuthuthwa.

Ukupakishwa kwentsimbi ye-Angle ekhandiweyo: Ukuba yintsimbi ye-Angle ekhandiweyo, izixhobo zokupakisha ezingangeni manzi nezingenamanzi, ezifana nefilimu yeplastiki engangeni manzi okanye ibhokisi engangeni manzi, zihlala zisetyenziselwa ukuthintela i-oxidation kunye nokugqwala.

Ukupakishwa komthi: Intsimbi e-engile enobukhulu okanye ubunzima obukhulu ingapakishwa ngomthi, njengeepalethi zomthi okanye iibhokisi zomthi, ukuze kubonelelwe ngenkxaso nokhuseleko olukhulu.

UKUTYELELA KWABATHENGI

FAQ

1. Ndingayifumana njani ikowuteshini kuwe?

Ungasishiyela umyalezo, kwaye siza kuphendula yonke imiyalezo ngexesha elifanelekileyo.

2. Ngaba uza kuzihambisa iimpahla ngexesha elifanelekileyo?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni ophezulu kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3. Ndingafumana iisampulu ngaphambi kokuba ndi-odole?

Ewe, ewe. Ngokwesiqhelo iisampulu zethu zisimahla, singazivelisa ngeesampulu zakho okanye ngemizobo yobugcisa.

4. Ithini imiqathango yakho yokuhlawula?

Ixesha lethu lokuhlawula eliqhelekileyo yidiphozithi ye-30%, kwaye intsalela ihambelana ne-B/L. EXW, FOB, CFR, CIF.

5. Ngaba uyayamkela into yokuhlolwa ngumntu wesithathu?

Ewe siyamkela ngokupheleleyo.

6. Siyithemba njani inkampani yakho?

Siziingcali kwishishini lentsimbi kangangeminyaka emininzi njengomthengisi wegolide, ikomkhulu likwiphondo laseTianjin, samkelekile ukuphanda ngazo zonke iindlela, nangayiphi na indlela.