Isinyithi Esishushu Esichasene Nokugqwala Esinomgangatho Ophezulu Esifakwe Intsimbi Egqunyiweyo Eyi-2 3 4 intshi C Intsimbi Yesiteshi

Ifanelekile kwiindawo ezahlukeneyo:Itshaneli ye-C egalelweyoziyakwazi ukuziqhelanisa neendawo ezahlukeneyo kunye neentlobo zomhlaba, kuquka umhlaba othe tyaba, iintaba, iintlango, iindawo ezimanzi, njl.

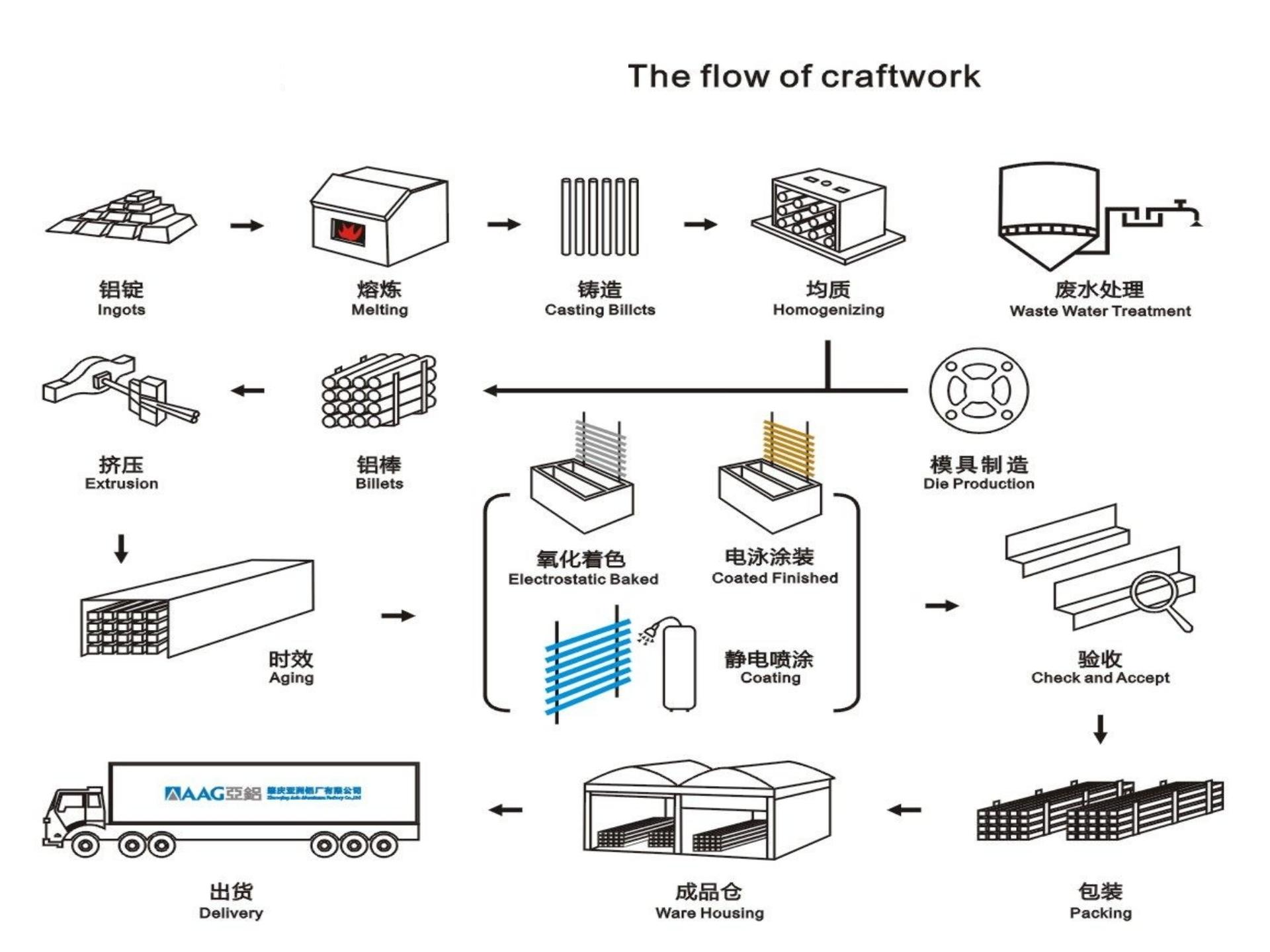

INKQUBO YOKUVELISA IMVELISO

UBUKHULU BEMVELISO

Isetyenziselwa ukuxhasa iipayipi, izixhobo kunye neenkqubo zokungenisa umoya ezivela kwiimitha kunye nezinye iinkqubo zesakhiwo.

| Igama lemveliso | Yenziwe eTshayina iHot Dip Galvanized Steel Slotted Strut Channel (Itshaneli ye-C, Unistrut, Uni Strut Channel) |

| Izinto eziphathekayo | Q195/Q235/SS304/SS316/Aluminiyam |

| Ubukhulu | 1.5mm/2.0mm/2.5mm |

| Uhlobo | 41*21,/41*41/41*62/41*82mm enemingxuma okanye engenanto |

| Ubude | 3m/3.048m/6m |

| Igqitywe tu | Igqunywe nge-galvanized/HDG/power |

| Hayi. | Ubungakanani | Ubukhulu | Uhlobo | Unyango Lomphezulu | ||

| mm | intshi | mm | Igeyiji | |||

| A | 41x21 | 1-5/8x13/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Ifakwe kwi-slot, Iqinile | GI,HDG,PC |

| B | 41x25 | 1-5/8x1" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Ifakwe kwi-slot, Iqinile | GI,HDG,PC |

| C | 41x41 | 1-5/8x1-5/8" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Ifakwe kwi-slot, Iqinile | GI,HDG,PC |

| D | 41x62 | 1-5/8x2-7/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Ifakwe kwi-slot, Iqinile | GI,HDG,PC |

| E | 41x82 | 1-5/8x3-1/4" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Ifakwe kwi-slot, Iqinile | GI,HDG,PC |

IINZUZO

Iimveliso zeSiteshi se-C ezifakwe kwi-Slottedineempawu ezintle kakhulu zoomatshini kunye nokusebenziseka lula. Ngoko ke zithini iingenelo zentsimbi enomfanekiso we-C? Makhe sazise kuwe.

1. Isakhiwo silula ngobunzima. Xa sithelekiswa nesakhiwo sekhonkrithi, esilula ngobunzima, ukunciphisa ubunzima besakhiwo kunciphisa amandla angaphakathi oyilo lwesakhiwo, nto leyo enokunciphisa imfuneko yokulungiswa okusisiseko kwesakhiwo sesakhiwo, yenze lula ulwakhiwo, kwaye inciphise iindleko.

2. Uyilo lwentsimbi olufana no-C luneempawu eziguquguqukayo nezityebileyo. Xa ukuphakama komqadi kufana, iibheyi zesakhiwo sentsimbi zinokuba nkulu ngama-50% kuneebheyi zesakhiwo sekhonkrithi, ngaloo ndlela zenza ukufakelwa kwesakhiwo kube lula ngakumbi.

3. Isakhiwo sentsimbi, ikakhulu intsimbi ejijekileyo enomfanekiso we-C, sinesakhiwo sesayensi nesifanelekileyo, iplastiki elungileyo kunye nokuguquguquka, kunye nozinzo oluphezulu lwesakhiwo. Sifanelekile kwizakhiwo zokwakha ezithwala imithwalo emikhulu yokungcangcazela kunye nefuthe. Sinokumelana okukhulu neentlekele zemvelo kwaye sifanelekile ngakumbi kwezinye izakhiwo kwiindawo ezithandwa yinyikima.

4. Yandisa indawo yokusetyenziswa ngokufanelekileyo kwesakhiwo. Xa kuthelekiswa nesakhiwo sekhonkrithi, indawo enqamlezileyo yekholamu yesakhiwo sentsimbi incinci, nto leyo enokunyusa indawo yokusetyenziswa ngokufanelekileyo kwesakhiwo. Ngokuxhomekeke kwiintlobo ezahlukeneyo zesakhiwo, indawo yokusetyenziswa ngokufanelekileyo inokwandiswa nge-4-6%.

5. Xa ithelekiswa nentsimbi ejijekileyo enomfanekiso we-C, inokonga kakhulu abasebenzi kunye nezixhobo, inciphise ukusetyenziswa kwezinto ezikrwada, amandla kunye nomsebenzi, inoxinzelelo oluphantsi olushiyekileyo, kwaye inembonakalo entle kunye nomgangatho womphezulu.

6. Ilungele ukwenziwa kwemishini, uqhagamshelo kunye nokufakelwa kwesakhiwo, kwaye kulula ukuyiqhaqha nokuphinda uyisebenzise.

Ukongeza, ukusetyenziswa kwentsimbi enomfanekiso ka-C kunokukhusela okusingqongileyo ngempumelelo, nto leyo ebonakala kwiinkalo ezintathu: okokuqala, xa kuthelekiswa nekhonkrithi, ulwakhiwo olomileyo lungasetyenziswa, oluvelisa ingxolo encinci kunye nothuli oluncinci; okwesibini, ngenxa yobunzima obuphantsi, umhlaba omncinci awufuneki kulwakhiwo olusisiseko, nto leyo ebangela umonakalo omncinci kwizixhobo zomhlaba kwaye inceda ekukhuseleni okusingqongileyo; okwesithathu, emva kokuba ixesha lokusebenza kwesakhiwo sesakhiwo liphelile, emva kokuba isakhiwo sichithiwe, ubungakanani benkunkuma eqinileyo eveliswayo buncinci, kwaye ixabiso lokurisayikilisha lezixhobo zentsimbi elahliweyo liphezulu.

UHLOLO LWEMVELISO

1. Ukwamkelwa koyilo

Ukwamkelwa koyilo linyathelo elibalulekileyo ekwamkelweniIimveliso zeStrut C Channel, ephonononga ikakhulu izicwangciso zoyilo lweebrakethi ze-photovoltaic. Ngexesha lenkqubo yokuphonononga, kufuneka uphonononge amaxwebhu oyilo kwaye ugxile kwezi zinto zilandelayo:

1. Ingaba uyilo lwe-photovoltaic bracket luyahlangabezana neemfuno zemigangatho yesizwe neyeshishini.

2. Nokuba uyilo lwebracket ye-photovoltaic luyasebenza, lungabizi, lukhuselekile kwaye luthembekile.

3. Ingaba isicwangciso soyilo lwe-photovoltaic bracket siyahlangabezana neemfuno zeprojekthi.

Ukwamkelwa kwemveliso ikakhulu kukujonga nokuhlola inkqubo yokwenziwa kweebrakethi ze-photovoltaic. Ngexesha lenkqubo yokuhlolwa, kufuneka kuqatshelwe ezi zinto zilandelayo:

1. Ukuhlolwa okungenayo kwezinto ezibalulekileyo (ezifana nentsimbi, njl.njl.).

2. Ukujonga nokuhlola inkqubo yokucubungula nokuvelisa iinxalenye.

3. Ukujonga nokuhlola inkqubo kunye nomgangatho wokuwelda.

Ukwamkelwa kofakelo kujonga ikakhulu kwiinkalo ezimbini: umgangatho wofakelo kunye nenqanaba lofakelo. Ngexesha lenkqubo yokuhlolwa, kufuneka kuqwalaselwe ezi nkalo zilandelayo:

1. Ingaba indawo yokufakela ibracket ye-photovoltaic ifanelekile kwaye iyahambelana nesicwangciso soyilo.

2. Ingaba umgangatho wofakelo lwebracket ye-photovoltaic uyahlangabezana neemfuno zoyilo.

3. Ingaba i-photovoltaic bracket izinzile kwaye ithembekile na.

4. Jonga ukuba imodyuli ye-photovoltaic ifakwe ngokuchanekileyo na, kwaye unikele ingqalelo kumgangatho woqhagamshelo phakathi kwemodyuli kunye ne-bracket.

1. Nika ingqalelo ekhethekileyo kwimo yezulu enganyangekiyo kwiibrakethi ze-photovoltaic kwaye uphephe ukugqwala.

2. Ngexesha lenkqubo yokwenziwa nokufakelwa kwezibiyeli ze-photovoltaic, kufuneka kugcinwe iirekhodi kunye neengxelo zokwakha, kwaye iisampulu mazigcinwe.

3. Idatha efanelekileyo kufuneka ihlelwe kwaye ihlolwe ngaphambi kokuba yamkelwe ukuze kuthintelwe ukuphinda kusetyenzwe kwaye kuthathe ixesha xa kufunyenwe iingxaki.

4. Ngexesha lomsebenzi wokwamkela, kufuneka kubekho unxibelelwano olupheleleyo nomnini ukuze kusonjululwe iingxaki kwaye kufunyanwe imvume.

Ngamafutshane, ukujongwa nokwamkelwa kwenkxaso ye-photovoltaic yindlela ebalulekileyo yokuqinisekisa inkqubela phambili ethe tye kwiiprojekthi zokuvelisa umbane we-photovoltaic. Kuphela ngumsebenzi wokwamkela ngokungqongqo apho umgangatho weebrakethi ze-photovoltaic ungaqinisekiswa kwaye ukusebenza kakuhle kokuvelisa umbane kuphuculwe.

IPROJEKTHI

Inkampani yethuUmthengisi weStrut C Channelithathe inxaxheba kwiprojekthi enkulu yophuhliso lwamandla elanga eMzantsi Melika, ibonelela ngeebrakethi kunye noyilo lwezisombululo. Sinikezele ngeetoni ezili-15,000 zeebrakethi ze-photovoltaic kule projekthi. Iibrakethi ze-photovoltaic zamkele ubuchwepheshe obutsha basekhaya ukunceda uphuhliso lweshishini le-photovoltaic eMzantsi Melika kunye nokuphucula abemi basekuhlaleni. Ubomi. Iprojekthi yenkxaso ye-photovoltaic ibandakanya isikhululo samandla se-photovoltaic esinomthamo ofakiweyo omalunga ne-6MW kunye nesikhululo samandla sokugcina amandla ebhetri se-5MW/2.5h. Ingavelisa malunga neeyure ezili-1,200 zee-kilowatt ngonyaka. Inkqubo inamandla okuguqula i-photoelectric kakuhle.

ISICELO

Iibrakethi ze-Photovoltaic zikwabizwa ngokuba ziibrakethi ze-solar photovoltaic. Sisixhobo sokongeza kwinkqubo yokuvelisa umbane we-solar photovoltaic. Umsebenzi wayo kukubeka, ukufaka kunye nokukhusela iiphaneli zelanga. Abavelisi beebrakethi ze-Photovoltaic badla ngokuvelisa iibrakethi ze-photovoltaic ezenziwe nge-aluminium alloy, i-carbon steel kunye ne-stainless steel. Phakathi kwazo, i-carbon steel kunye ne-stainless steel zisetyenziswa njengezixhobo ezibalulekileyo zamandla elanga.

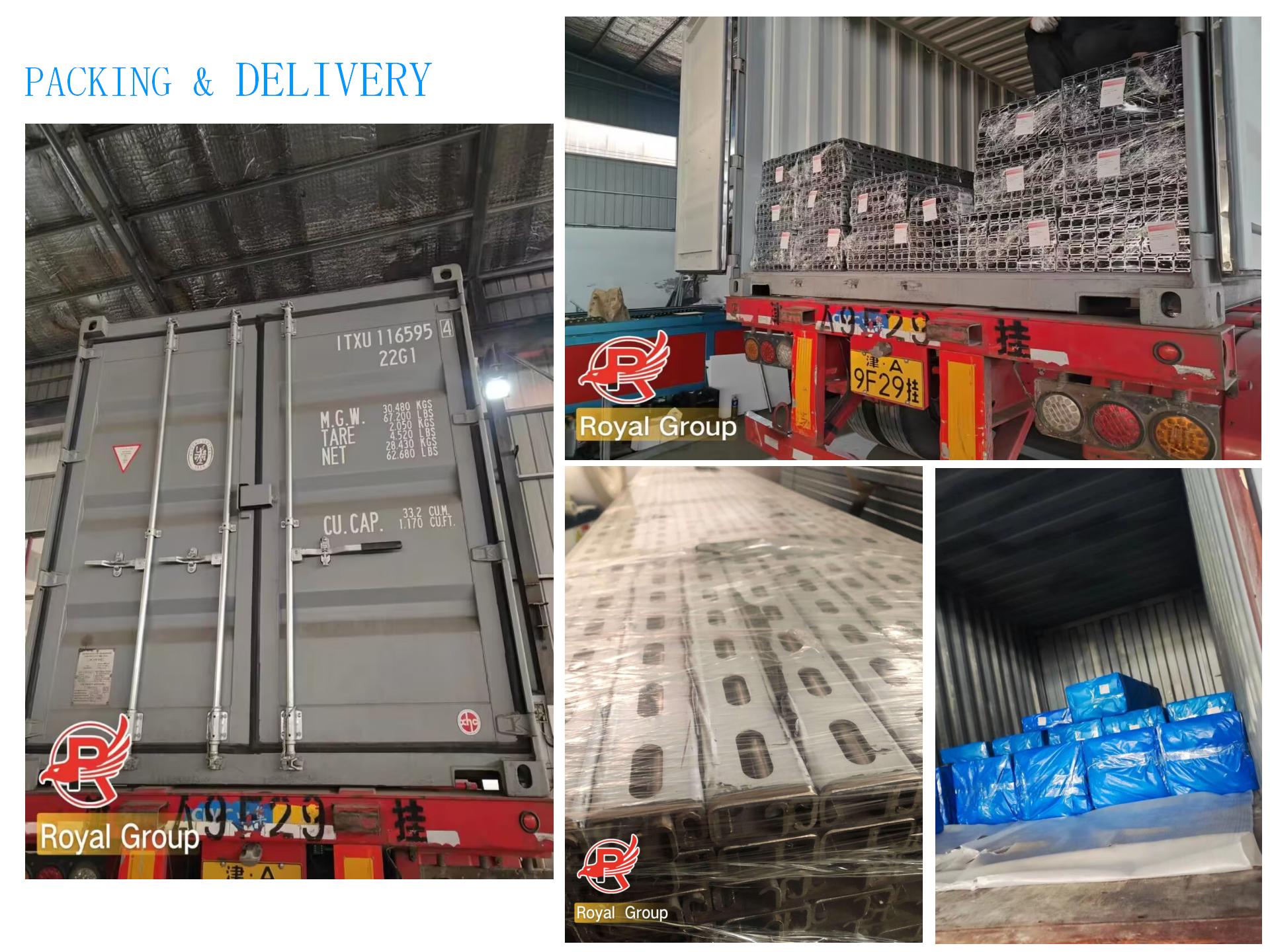

UKUPAKISHA NOKUTHUMELA

1. Ukupakisha imodyuli ye-Photovoltaic

Ukupakishwa kweemodyuli ze-photovoltaic kujoliswe kakhulu ekukhuseleni imiphezulu yazo yeglasi kunye neenkqubo zezibiyeli kunye nokuthintela ukungqubana kunye nomonakalo ngexesha lokuthuthwa. Ke ngoko, ekupakishweni kweemodyuli ze-photovoltaic, ezi zinto zilandelayo zokupakishwa zisetyenziswa rhoqo:

1. Ibhokisi yefoam: Sebenzisa ibhokisi yefoam eqinileyo xa upakisha. Ibhokisi yenziwe ngekhadibhodi enamandla aphezulu okanye ibhokisi yomthi, enokukhusela ngempumelelo iimodyuli ze-photovoltaic kwaye ilungele ngakumbi ukuthuthwa kunye nemisebenzi yokuphatha.

2. Iibhokisi zomthi: Cinga ngokupheleleyo ukuba izinto ezinzima zinokungqubana, zicinezelwe, njl.njl. ngexesha lokuthuthwa, ngoko ke ukusebenzisa iibhokisi zomthi eziqhelekileyo kuya kuba namandla ngakumbi. Nangona kunjalo, le ndlela yokupakisha ithatha indawo ethile kwaye ayilungelanga ukukhuselwa kwendalo.

3. Ipalethi: Ipakishwe kwipalethi ekhethekileyo ize ibekwe kwikhadibhodi ebotshelelweyo, enokubamba iiphaneli ze-photovoltaic ngokuzinzileyo kwaye iqinile kwaye kulula ukuyithutha.

4. I-Plywood: I-Plywood isetyenziselwa ukulungisa iimodyuli ze-photovoltaic ukuqinisekisa ukuba azinakungqubana okanye ziphume ukuze kuthintelwe umonakalo okanye ukuguquka ngexesha lokuthuthwa.

2. Ukuthuthwa kweemodyuli ze-photovoltaic

Kukho iindlela ezintathu eziphambili zothutho lweemodyuli ze-photovoltaic: uthutho lomhlaba, uthutho lwaselwandle, kunye nothutho lomoya. Indlela nganye ineempawu zayo.

1. Uthutho lomhlaba: Lusebenza kwezothutho ngaphakathi kwisixeko okanye kwiphondo elinye, umgama omnye wothutho ungadluli kwiikhilomitha ezili-1,000. Iinkampani zothutho ngokubanzi kunye neenkampani zezothutho zinokuthutha iimodyuli ze-photovoltaic ukuya kwiindawo zazo ngothutho lomhlaba. Ngexesha lothutho, qaphela ukuze uphephe ukungqubana kunye nokuphuma, kwaye ukhethe inkampani yothutho yobungcali yokusebenzisana kangangoko kunokwenzeka.

2. Uthutho lwaselwandle: lufanelekile kuthutho oluphakathi kwamaphondo, oluwela imida kunye noluhamba umgama omde. Nika ingqalelo ekupakisheni, ekukhuseleni nasekunyameni, kwaye zama ukukhetha inkampani enkulu yezothutho okanye inkampani yokuthutha enobuchule njengeqabane.

3. Uthutho ngomoya: lufanelekile kuthutho olunqumla imida okanye olude, nto leyo enokunciphisa kakhulu ixesha lokuthuthwa. Nangona kunjalo, iindleko zothutho ngomoya ziphezulu kwaye kufuneka amanyathelo okhuseleko afanelekileyo.

AMANDLA ENKAMPANI

Yenziwe eTshayina, inkonzo yodidi oluphezulu, umgangatho ophezulu, idume kwihlabathi liphela

1. Isiphumo sesikali: Inkampani yethu inekhonkco elikhulu lokubonelela ngempahla kunye nomzi-mveliso omkhulu wentsimbi, ifikelela kwiziphumo zesikali kwezothutho kunye nokuthengwa kwempahla, kwaye iba yinkampani yentsimbi edibanisa imveliso kunye neenkonzo.

2. Ukwahluka kwemveliso: Ukwahluka kwemveliso, nayiphi na intsimbi oyifunayo ingathengwa kuthi, ikakhulu ibandakanya izakhiwo zentsimbi, iireyile zentsimbi, iipali zeshiti zentsimbi, izibiyeli ze-photovoltaic, intsimbi yetshaneli, iikhoyili zesinyithi zesilicon kunye nezinye iimveliso, nto leyo eyenza ukuba iguquguquke ngakumbi Khetha uhlobo lwemveliso oyifunayo ukuhlangabezana neemfuno ezahlukeneyo.

3. Ubonelelo oluzinzileyo: Ukuba nomgca wemveliso ozinzileyo kunye nochungechunge lobonelelo kunokubonelela ngobonelelo oluthembekileyo ngakumbi. Oku kubaluleke kakhulu kubathengi abafuna intsimbi eninzi.

4. Impembelelo yophawu: Banempembelelo ephezulu yophawu kunye nemarike enkulu

5. Inkonzo: Inkampani enkulu yentsimbi edibanisa ukwenziwa ngokwezifiso, uthutho kunye nemveliso

6. Ukhuphiswano lwamaxabiso: ixabiso elifanelekileyo

*Thumela i-imeyile ku[i-imeyile ikhuselwe]ukuze ufumane ikowuteshini yeeprojekthi zakho

UKUTYELELA KWABATHENGI

FAQ

1. Ndingayifumana njani ikowuteshini kuwe?

Ungasishiyela umyalezo, kwaye siza kuphendula yonke imiyalezo ngexesha elifanelekileyo.

2. Ngaba uza kuzihambisa iimpahla ngexesha elifanelekileyo?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni ophezulu kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3. Ndingafumana iisampulu ngaphambi kokuba ndi-odole?

Ewe, ewe. Ngokwesiqhelo iisampulu zethu zisimahla, singazivelisa ngeesampulu zakho okanye ngemizobo yobugcisa.

4. Ithini imiqathango yakho yokuhlawula?

Ixesha lethu lokuhlawula eliqhelekileyo yidiphozithi ye-30%, kwaye intsalela ihambelana ne-B/L. EXW, FOB, CFR, CIF.

5. Ngaba uyayamkela into yokuhlolwa ngumntu wesithathu?

Ewe siyamkela ngokupheleleyo.

6. Siyithemba njani inkampani yakho?

Siziingcali kwishishini lentsimbi kangangeminyaka emininzi njengomthengisi wegolide, ikomkhulu likwiphondo laseTianjin, samkelekile ukuphanda ngazo zonke iindlela, nangayiphi na indlela.