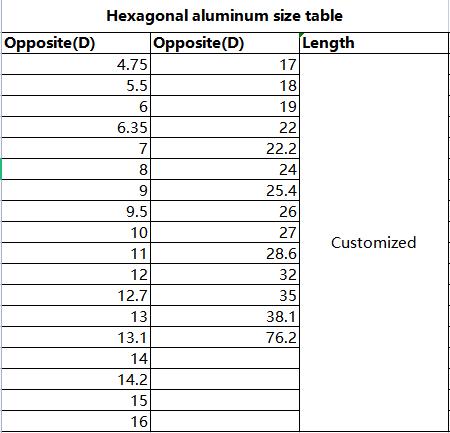

Umthengisi waseTshayina i-Extruded Hexagonal Aluminium Rod Long Hexagon Bar 12mm 2016 astm 233

Iinkcukacha zeMveliso

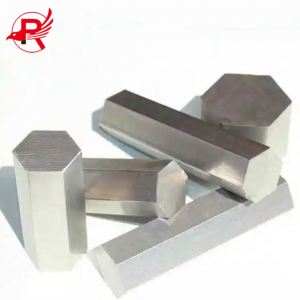

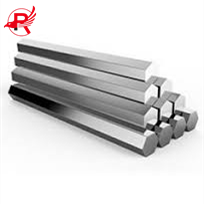

Intonga ye-aluminiyam enesiqingatha yimveliso ye-aluminiyam enesimo se-prism esinama-hexagonal, esisixhobo esisetyenziswa kakhulu kushishino.

Intonga ye-aluminiyam ene-hexagonal ineempawu zobunzima obulula, ukuqina okuhle, amandla aphezulu kunye nokuqhuba kakuhle, kwaye isetyenziswa kakhulu njengezinto zokusasaza ubushushu kunye nezinto zokwakha kwizixhobo ze-elektroniki nezombane.

Ngenxa yeempawu zesakhiwo esinamacala asibhozo, ifanelekile kakhulu ekwenzeni iindawo kunye neemolds zeemilo ezahlukeneyo.

Iinkcukacha

Kwishishini lokuvelisa oomatshini, isetyenziswa kakhulu ekwenzeni iidayi ezahlukeneyo zokunyathela; ekucubungulweni kwezixhobo zekhompyutha, isetyenziselwa ukwenza izixhobo ezahlukeneyo zesinyithi, iipayipi kunye neendawo ezahlukeneyo ezinemilo ekhethekileyo; kwishishini leemoto, ingasetyenziselwa iinkqubo zokupholisa ezifana neebhloko zeenjini kunye needrama zeebhuleki kunye nepleyiti yokungqubana ekuyo; ukongeza, ingasetyenziselwa njengesixhobo sonyango lokulwa nokugqwala kwizixhobo zeekhemikhali, njl.

Isicelo

1. Ifanelekile kwiimveliso ze-elektroniki nezombane njengezixhobo zokusasaza ubushushu okanye iindawo zesakhiwo, ezinje ngee-radiator, ii-evaporator, ii-condenser kunye nezinye izixhobo zokusasaza ubushushu.

2. Isetyenziswa kwinkqubo yokupholisa yebhloko yenjini kwishishini leemoto kunye nepleyiti yokungqubana kwidrama yebrake; ingasetyenziswa njengesixhobo sonyango lokulwa nokugqwala kwizixhobo zeshishini leekhemikhali.

3. Ingatshintsha iindawo zobhedu njenge-solder ngexesha lokuwelda, ezinje: intloko yesinyithi edibanisa ngombane, umlomo wesibhamu somoya oshushu, ucingo lwe-solder, ibhola ye-solder njl.

4. Ingasetyenziswa endaweni yokucima intsimbi kwiindawo zentsimbi.

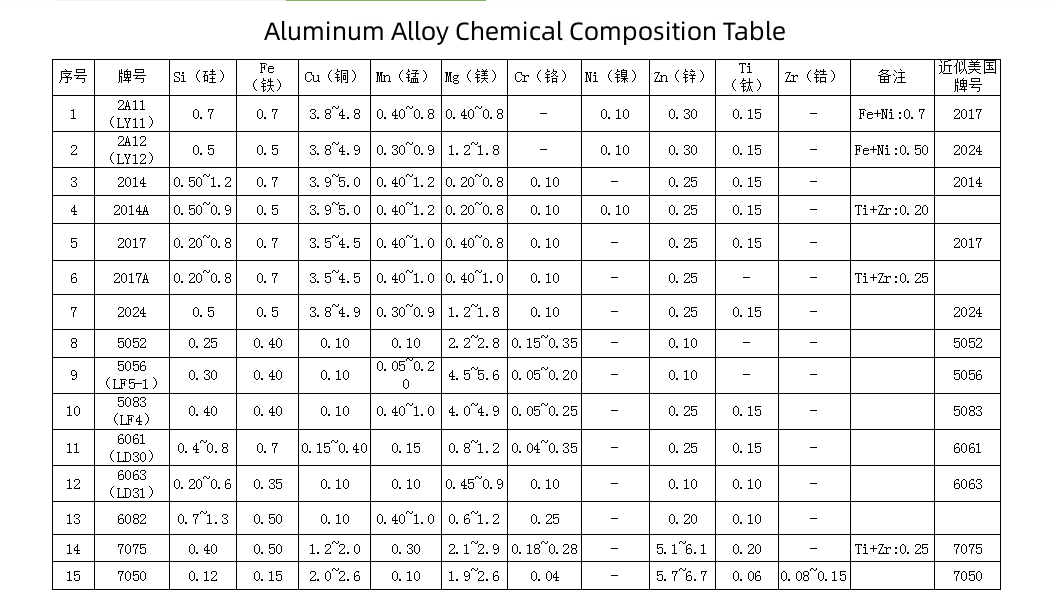

Izinto ze-aluminium. Ezi zilandelayo zisebenzisa ikakhulu i-aluminium alloy ye-6061 njengomzekelo wokwazisa:

I-aluminium Alloy ye-6061

I-aluminium alloy ye-6061 yi-alloy enyangwa ngobushushu enokwakheka kakuhle, ukudityaniswa, ukusebenza kakuhle, kunye namandla aphakathi, kwaye isenokuhlala isebenza kakuhle emva kokutsalwa.

Ulwakhiwo lweekhemikhali ze-aluminium alloy ezingama-6061 (%):

Cu: 0.15~0.4 Mn:0.15 Mg:0.8~1.2Zn: 0.25 Cr: 0.04~0.35 Ti: 0.15 Si:0.4~0.8 Fe: 0.7 Al: ibhalansi

Eyona njongo iphambili: Isetyenziswa kakhulu kwiindawo ezahlukeneyo zesakhiwo semizi-mveliso ezifuna amandla athile kunye nokumelana nokugqwala okuphezulu, njengeelori zokwenza izinto, izakhiwo zeenqaba, iinqanawa, iitram, kunye nezithuthi zikaloliwe. Iimpawu ze-aluminium alloy ezingama-6061:

Amandla okutsalwa kwe-aluminium alloy ye-6061 yi-124MPa, amandla okutsalwa kwe-aluminium yi-5.2MPa, izinga lokunwebeka yi-25.0%, i-modulus yokuthamba yi-68.9 GPa, kwaye amandla okugoba aphezulu yi-28MPa.

I-6061 isetyenziswa kakhulu kwizixhobo zeenqwelo-moya, iilori, izakhiwo zeenqaba, iipayipi, iinqanawa, iinqwelo-moya, izindiza, ukhuselo kunye nezinye izixhobo zokwakha ezifuna amandla, ukudityaniswa kunye nokumelana nokugqwala.

I-aluminium alloy ye-6061 inezi nzuzo zilandelayo: 1. I-alloy enamandla aphezulu enyangwa bubushushu. 2. Iipropati ezilungileyo zoomatshini. 3. Isebenziseka kakuhle. 4. Kulula ukuyicubungula, iyamelana nokuguguleka kakuhle. 5. Iyamelana nokugqwala kakuhle kunye nokumelana nokubola

I-aluminium alloy ye-6061 isetyenziswa kakhulu kwizixhobo zeenqwelo-moya, iilori, izakhiwo zeenqaba, iipayipi, iinqanawa, iinqwelo-moya, iindiza, ukhuselo kunye nezinye izixhobo zokwakha ezifuna amandla, ukudityaniswa kunye nokumelana nokugqwala. Ezifana: iindawo zeenqwelo-moya, iigiya kunye neeshafti, iindawo zefuse, iishafti zezixhobo kunye neegiya, iindawo zokhuseleko zevalvu yokutsiba, iiturbine, izitshixo, njl.njl.

Yi-alloy ye-A-Mg-Si enamandla aphakathi, i-plasticity elungileyo kunye nokumelana nokugqwala okugqwesileyo. Ngokukodwa, akukho mkhwa wokuqhekeka kokugqwala koxinzelelo, ukudityaniswa kwayo kugqwesileyo, ukumelana nokugqwala kunye nokusebenza ngokubanda kulungile, luhlobo lokusetyenziswa okubanzi. I-alloy ethembisayo kakhulu. Ingafakwa i-anodized kwaye ipeyintwe ngemibala, kwaye ingapeyintwa nge-enamel, efanelekileyo kwizixhobo zokuhombisa zokwakha. Iqulethe inani elincinci le-Cu, ngoko ke amandla ayo aphezulu kune-6063, kodwa inovelwano ekucimeni.

3, Iimpawu kunye neendlela zokuphucula iiCandelo zeSitimela:

Ikwangaphezulu kune-6063. Ukucima umoya akunakufezekiswa emva kokukhupha umoya, kwaye kufuneka kulungiswe kwakhona kwaye kucinywe ukuze kufunyanwe amandla aphezulu.

Izinto eziphambili zokudibanisa igolide yaseTaiwan eyi-6061 yi-magnesium kunye ne-silicon, kwaye zenza isigaba se-Mg2Si. Ukuba iqulethe inani elithile le-manganese kunye ne-chromium, inokuphelisa isiphumo esibi sesinyithi; ngamanye amaxesha inani elincinci le-copper okanye i-zinc longezwa ukuphucula ubulukhuni be-alloy.

Amandla ngaphandle kokunciphisa kakhulu ukumelana nokugqwala kwayo; kukho inani elincinci lobhedu kwizinto eziqhubayo ukuze kuthintelwe imiphumo emibi ye-titanium kunye nesinyithi ekuqhubeni; i-aluminium okanye i-titanium inokucokisa iinkozo kwaye ilawule isakhiwo se-recrystallization;

Ukuze kuphuculwe ukusebenza kakuhle kwe-machinability, i-lead kunye ne-bismuth zingongezwa. Isisombululo esiqinileyo se-Mg2Si kwi-aluminium senza i-alloy ibe nomsebenzi wokuqinisa ukuguga okwenziweyo.

I-6061-T651 yeyona ngxubevange iphambili ye-6061 alloy. Yimveliso ye-aluminium alloy esemgangathweni ophezulu eyenziwe ngonyango lobushushu kunye nenkqubo yokusolula kwangaphambili. Nangona amandla ayo engenakuthelekiswa nothotho lwe-2XXX okanye uthotho lwe-7XXX, i-magnesium kunye ne-silicon alloys zayo zikhethekile.

Ineempawu ezininzi, ukusebenza kakuhle kokucubungula, iimpawu ezibalaseleyo zokuwelda kunye neempawu ze-electroplating, ukumelana nokugqwala okuhle, ukuqina okuphezulu kunye nokungabi nanguquko emva kokucubungula, izinto ezixineneyo ezingenaziphene kwaye kulula ukuzipolisha, kulula ukuyifaka ifilimu yombala, isiphumo esihle kakhulu se-oxidation kunye nezinye iimpawu ezibalaseleyo.

4, Itshathi yokuhamba kwemveliso kaloliwe:

Ukunyibilikisa → ukuphosa → iintonga zokusarha → iintonga zealuminiyam ezihomogenizing → ukupholisa, ukuhlamba iintonga → iintonga zealuminiyam zingene kwindawo yokugcina impahla.

FAQ

1. Ndingayifumana njani ikowuteshini kuwe?

Ungasishiyela umyalezo, kwaye siza kuphendula yonke imiyalezo ngexesha elifanelekileyo.

2. Ngaba uza kuzihambisa iimpahla ngexesha elifanelekileyo?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni ophezulu kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3. Ndingafumana iisampulu ngaphambi kokuba ndi-odole?

Ewe, ewe. Ngokwesiqhelo iisampulu zethu zisimahla, singazivelisa ngeesampulu zakho okanye ngemizobo yobugcisa.

4. Ithini imiqathango yakho yokuhlawula?

Ixesha lethu lokuhlawula eliqhelekileyo yidiphozithi ye-30%, kwaye intsalela ihambelana ne-B/L. EXW, FOB, CFR, CIF.

5. Ngaba uyayamkela into yokuhlolwa ngumntu wesithathu?

Ewe siyamkela ngokupheleleyo.

6. Siyithemba njani inkampani yakho?

Siziingcali kwishishini lentsimbi kangangeminyaka emininzi njengomthengisi wegolide, ikomkhulu likwiphondo laseTianjin, samkelekile ukuphanda ngazo zonke iindlela, nangayiphi na indlela.