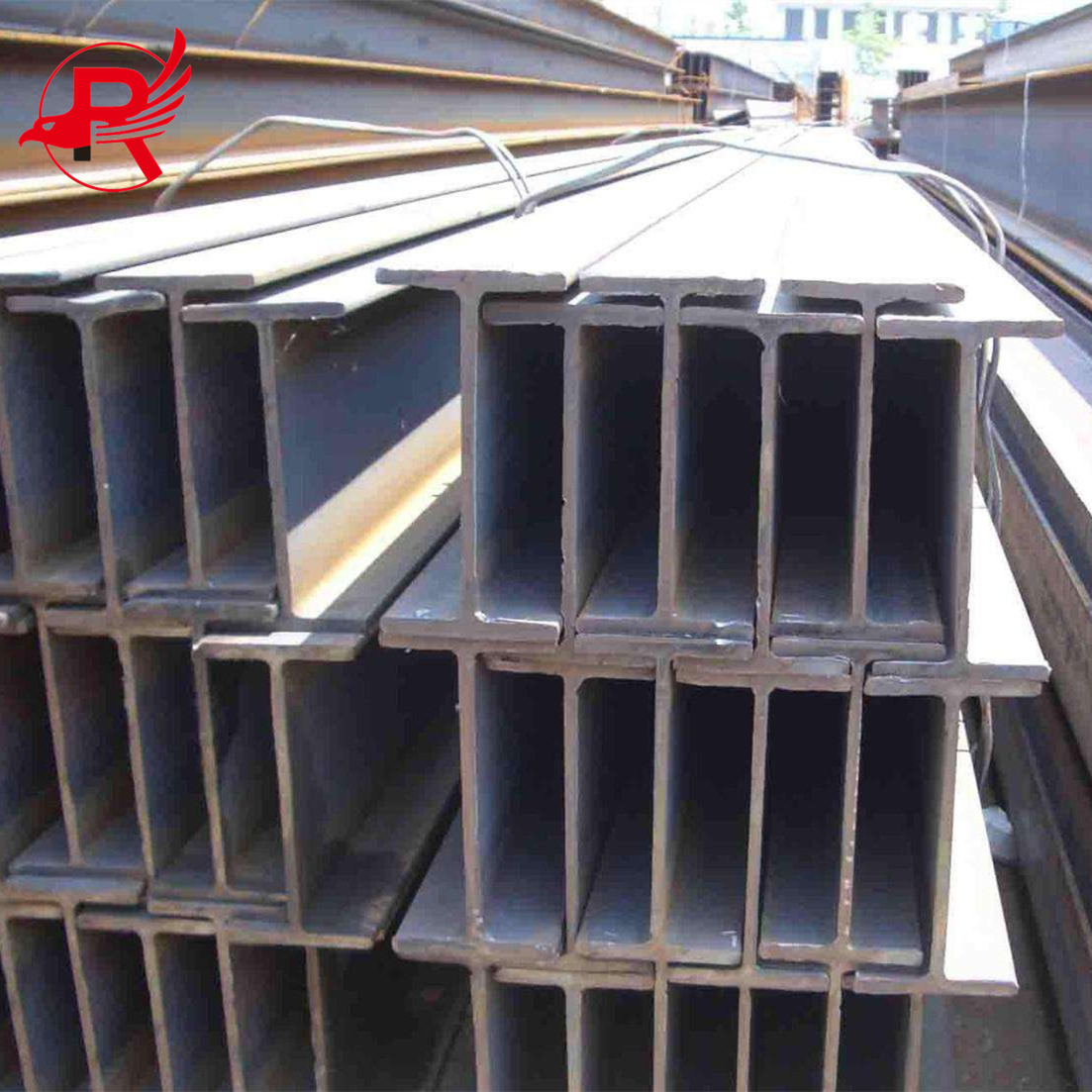

I-HEA HEB HEM H Beam I-H Beam yentsimbi emile okwe-H – Iibhanti zeFlange ezibanzi zaseYurophu

INKQUBO YOKUVELISA IMVELISO

Ezi mpawu zibonisa iintlobo ezahlukeneyo zemiqadi ye-IPE ngokusekelwe kubukhulu kunye neempawu zayo:

- Imisebe ye-HEA (IPN): Ezi ziimitha ze-IPE ezinobubanzi beflange ebanzi kakhulu kunye nobukhulu beflange, nto leyo eyenza ukuba zifaneleke ukusetyenziswa kwizicelo zesakhiwo ezinzima.

- Imisebe ye-HEB (IPB): Le yimisebe ye-IPE enobubanzi obuphakathi beflengi kunye nobukhulu beflengi, esetyenziswa rhoqo ekwakheni ngeenjongo ezahlukeneyo zesakhiwo.

- Imiqadi yeHEM: Le yimiqadi ye-IPE eneflange enzulu nemxinwa, enika amandla angakumbi kunye nomthamo wokuthwala umthwalo.

Siyakubona okoI-6m S275jr H-Beamisetyenziswa rhoqo kwizakhiwo. Ezi planga zenzelwe ukubonelela ngezakhono ezithile zokwakha, kwaye ukhetho lohlobo oluza kusetyenziswa luxhomekeke kwiimfuno zeprojekthi ethile yokwakha.

UBUKHULU BEMVELISO

| Ukutyunjwa | Unt Ubunzima kg/m) | Icandelo Eliqhelekileyo ukukhulisa mm | Icandelo UAma (cm² | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE28 | AA | 61.3 | 264.0 | 280.0 | 7.0 | 10.0 | 24.0 | 78.02 |

| A | 76.4 | 270.0 | 280.0 | 80 | 13.0 | 24.0 | 97.26 | |

| B | 103 | 280.0 | 280.0 | 10.5 | 18.0 | 24.0 | 131.4 | |

| M | 189 | 310.0 | 288.0 | 18.5 | 33.0 | 24.0 | 240.2 | |

| HE300 | AA | 69.8 | 283.0 | 300.0 | 7.5 | 10.5 | 27.0 | 88.91 |

| A | 88.3 | 200.0 | 300.0 | 85 | 14.0 | 27.0 | 112.5 | |

| B | 117 | 300.0 | 300.0 | 11.0 | 19.0 | 27.0 | 149.1 | |

| M | 238 | 340.0 | 310.0 | 21.0 | 39.0 | 27.0 | 303.1 | |

| HE320 | AA | 74.3 | 301.0 | 300.0 | 80 | 11.0 | 27.0 | 94.58 |

| A | 97.7 | 310.0 | 300.0 | 9.0 | 15.5 | 27.0 | 124.4 | |

| B | 127 | 320.0 | 300.0 | 11.5 | 20.5 | 27.0 | 161.3 | |

| M | 245 | 359.0 | 309.0 | 21.0 | 40.0 | 27.0 | 312.0 | |

| HE340 | AA | 78.9 | 320.0 | 300.0 | 85 | 11.5 | 27.0 | 100.5 |

| A | 105 | 330.0 | 300.0 | 9.5 | 16.5 | 27.0 | 133.5 | |

| B | 134 | 340.0 | 300.0 | 12.0 | 21.5 | 27.0 | 170.9 | |

| M | 248 | 377.0 | 309.0 | 21.0 | 40.0 | 27.0 | 315.8 | |

| HE360 | AA | 83.7 | 339.0 | 300.0 | 9.0 | t2.0 | 27.0 | 106.6 |

| A | 112 | 350.0 | 300.0 | 10.0 | 17.5 | 27.0 | 142.8 | |

| B | 142 | 360.0 | 300.0 | 12.5 | 22.5 | 27.0 | 180.6 | |

| M | 250 | 395.0 | 308.0 | 21.0 | 40.0 | 27.0 | 318.8 | |

| HE400 | AA | 92.4 | 3780 | 300.0 | 9.5 | 13.0 | 27.0 | 117.7 |

| A | 125 | 390.0 | 300.0 | 11.0 | 19.0 | 27.0 | 159.0 | |

| B | 155 | 400.0 | 300.0 | 13.5 | 24.0 | 27.0 | 197.8 | |

| M | 256 | 4320 | 307.0 | 21.0 | 40.0 | 27.0 | 325.8 | |

| HE450 | AA | 99.8 | 425.0 | 300.0 | 10.0 | 13.5 | 27.0 | 127.1 |

| A | 140 | 440.0 | 300.0 | 11.5 | 21.0 | 27.0 | 178.0 | |

| B | 171 | 450.0 | 300.0 | 14.0 | 26.0 | 27.0 | 218.0 | |

| M | 263 | 4780 | 307.0 | 21.0 | 40.0 | 27.0 | 335.4 | |

| Ukumisela | Iyunithi Ubunzima kg/m) | Icandelo Eliqhelekileyo Ububanzi (mm) | ICandelo Indawo (cm²) | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE50 | AA | 107 | 472.0 | 300.0 | 10.5 | 14.0 | 27.0 | 136.9 |

| A | 155 | 490.0 | 300.0 | t2.0 | 23.0 | 27.0 | 197.5 | |

| B | 187 | 500.0 | 300.0 | 14.5 | 28.0 | 27.0 | 238.6 | |

| M | 270 | 524.0 | 306.0 | 21.0 | 40.0 | 27.0 | 344.3 | |

| HE550 | AA | t20 | 522.0 | 300.0 | 11.5 | 15.0 | 27.0 | 152.8 |

| A | 166 | 540.0 | 300.0 | t2.5 | 24.0 | 27.0 | 211.8 | |

| B | 199 | 550.0 | 300.0 | 15.0 | 29.0 | 27.0 | 254.1 | |

| M | 278 | 572.0 | 306.0 | 21.0 | 40.0 | 27.0 | 354.4 | |

| HE60 | AA | t29 | 571.0 | 300.0 | t2.0 | 15.5 | 27.0 | 164.1 |

| A | 178 | 500.0 | 300.0 | 13.0 | 25.0 | 27.0 | 226.5 | |

| B | 212 | 600.0 | 300.0 | 15.5 | 30.0 | 27.0 | 270.0 | |

| M | 286 | 620.0 | 305.0 | 21.0 | 40.0 | 27.0 | 363.7 | |

| HE650 | AA | 138 | 620.0 | 300.0 | t2.5 | 16.0 | 27.0 | 175.8 |

| A | 190 | 640.0 | 300.0 | t3.5 | 26.0 | 27.0 | 241.6 | |

| B | 225 | 660.0 | 300.0 | 16.0 | 31.0 | 27.0 | 286.3 | |

| M | 293 | 668.0 | 305.0 | 21.0 | 40.0 | 27.0 | 373.7 | |

| HE700 | AA | 150 | 670.0 | 300.0 | 13.0 | 17.0 | 27.0 | 190.9 |

| A | 204 | 600.0 | 300.0 | 14.5 | 27.0 | 27.0 | 260.5 | |

| B | 241 | 700.0 | 300.0 | 17.0 | 32.0 | 27.0 | 306.4 | |

| M | 301 | 716.0 | 304.0 | 21.0 | 40.0 | 27.0 | 383.0 | |

| HE800 | AA | 172 | 770.0 | 300.0 | 14.0 | 18.0 | 30.0 | 218.5 |

| A | 224 | 790.0 | 300.0 | 15.0 | 28.0 | 30.0 | 285.8 | |

| B | 262 | 800.0 | 300.0 | 17.5 | 33.0 | 30.0 | 334.2 | |

| M | 317 | 814.0 | 303.0 | 21.0 | 40.0 | 30.0 | 404.3 | |

| HE800 | AA | 198 | 870.0 | 300.0 | 15.0 | 20.0 | 30.0 | 252.2 |

| A | 252 | 800.0 | 300.0 | 16.0 | 30.0 | 30.0 | 320.5 | |

| B | 291 | 900.0 | 300.0 | 18.5 | 35.0 | 30.0 | 371.3 | |

| M | 333 | 910.0 | 302.0 | 21.0 | 40.0 | 30.0 | 423.6 | |

| HEB1000 | AA | 222 | 970.0 | 300.0 | 16.0 | 21.0 | 30.0 | 282.2 |

| A | 272 | 0.0 | 300.0 | 16.5 | 31.0 | 30.0 | 346.8 | |

| B | 314 | 1000.0 | 300.0 | 19.0 | 36.0 | 30.0 | 400.0 | |

| M | 349 | 1008 | 302.0 | 21.0 | 40.0 | 30.0 | 444.2 | |

EI-NHIntsimbi Emile

Udidi: EN10034:1997 EN10163-3:2004

Inkcazo: I-HEA HEB kunye ne-HEM

Umgangatho: EN

IIMBONAKALO

Imiqadi ye-HEA, i-HEB, kunye ne-HEM ziinxalenye ze-IPE (I-beam) zaseYurophu ezisetyenziswa kulwakhiwo nobunjineli bezakhiwo. Nazi ezinye zeempawu eziphambili zohlobo ngalunye:

Imisebe ye-HEA (IPN):

Ububanzi beflengi ebanzi kunye nobukhulu beflengi

Ifanelekile kwizicelo zesakhiwo ezinzima

Inika amandla okuthwala umthwalo kunye nokumelana nokugoba

Imisebe ye-HEB (IPB):

Ububanzi beflengi ephakathi kunye nobukhulu beflengi

Ziyasebenziseka kwaye zisetyenziswa rhoqo ekwakheni ngeenjongo ezahlukeneyo zokwakha

Inika ibhalansi yamandla kunye nobunzima

Imisebe yeHEM:

I-flange enzulu nemxinwa ngakumbi

Inika amandla anyukileyo kunye nomthamo wokuthwala umthwalo

Yenzelwe ukusetyenziswa kwezicelo ezinzima nezixinezelekileyo

Ezi planga zenzelwe ukuhlangabezana neemfuno ezithile zesakhiwo kwaye zikhethwa ngokusekelwe kusetyenziso olucetywayo kunye neemfuno zokuthwala umthwalo wesakhiwo okanye isakhiwo.

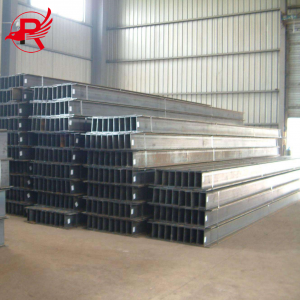

ISICELO

Imisebe ye-HEA, HEB, kunye ne-HEMZineentlobo ngeentlobo zezicelo kushishino lobunjineli bokwakha nolwakhiwo. Ezinye zeendlela ezisetyenziswa kakhulu ziquka:

- Ukwakhiwa kweZakhiwo:Imiqadi yentsimbi emile okwe-HZisetyenziswa rhoqo ekwakhiweni kwezakhiwo zorhwebo nezemizi-mveliso ukubonelela ngenkxaso yesakhiwo semigangatho, uphahla, kunye nezinye izinto ezithwala imithwalo.

- Ukwakhiwa kweBhulorho: Zisetyenziswa ekwakhiweni kweebhulorho ukuxhasa iidekhi zendlela kunye nezinye izinto ezakhiweyo.

- Izakhiwo zeMizi-mveliso: Iibhari ze-HEA, i-HEB, kunye ne-HEM zisetyenziswa kakhulu ekwakhiweni kwezakhiwo zoshishino ezifana neendawo zokugcina impahla, izityalo zokuvelisa, kunye neendawo zokugcina izinto.

- Izakhelo zoLwakhiwo: Zisetyenziselwa ukwenza izakhelo zolwakhiwo lwezakhiwo ezinkulu kunye neeprojekthi zeziseko, zibonelela ngenkxaso kwiindonga, ii-cladding, kunye nezinye izinto zesakhiwo.

- Inkxaso yeZixhobo: Ezi mitha zisetyenziselwa ukuxhasa oomatshini abanzima kunye nezixhobo kwiindawo ezahlukeneyo zoshishino.

- Iiprojekthi zeZiseko zoPhuhliso: Iibhari ze-HEA, i-HEB, kunye ne-HEM nazo zisetyenziswa ekwakhiweni kweeprojekthi zeziseko zophuhliso ezifana neetonela, izikhululo zeenqwelo-moya, kunye nezikhululo zombane.

Lilonke, le miqadi ibalulekile ekuboneleleni ngenkxaso eqinileyo nethembekileyo yesakhiwo kwiiprojekthi ezahlukeneyo zokwakha nezobunjineli. Ukuguquguquka kwazo, amandla, kunye nomthamo wazo wokuthwala umthwalo kuzenza zibe yinxalenye ebalulekileyo kuyilo lwezakhiwo zanamhlanje kunye neziseko zophuhliso.

UHLOLO LWEMVELISO

Iimfuno zokuhlolwa kwentsimbi enomfanekiso we-H ziquka ikakhulu ezi zinto zilandelayo:

Umgangatho wenkangeleko: Umgangatho wenkangeleko yentsimbi enomfanekiso we-H kufuneka uhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola. Umphezulu kufuneka ube bushelelezi kwaye uthe tyaba, ungabi nazimbobo, imikrwelo, umhlwa kunye nezinye iziphene ezicacileyo.

Ubukhulu bejometri: Ubude, ububanzi, ukuphakama, ubukhulu bewebhu, ubukhulu beflange kunye nezinye izilinganiso zentsimbi enomfanekiso we-H kufuneka zihambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola.

Ukugoba: Ukugoba kwentsimbi enomfanekiso we-H kufuneka kuhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola. Kungabonwa ngokulinganisa ukuba iiplani kuzo zombini iziphelo zentsimbi enomfanekiso we-H ziyafana okanye kusetyenziswa imitha yokugoba.

Ukujika: Ukujika kwentsimbi enomfanekiso we-H kufuneka kuhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola. Kungabonwa ngokulinganisa ukuba icala lentsimbi enomfanekiso we-H lithe nkqo okanye linemitha yokujika.

Ukuphambuka kobunzima: Ubunzima bentsimbi enomfanekiso we-H kufuneka buhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola. Ukuphambuka kobunzima kunokubonwa ngokubeka umlinganiselo.

Ukwakheka kweekhemikhali: Ukuba intsimbi enomfanekiso we-H kufuneka idityaniswe okanye icutshungulwe ngenye indlela, ukwakheka kwayo kweekhemikhali kufuneka kuhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola.

Iimpawu zoomatshini: Iimpawu zoomatshini zentsimbi enomfanekiso we-H kufuneka zihambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola, kubandakanya amandla okutsalwa, indawo yokukhupha, ukunwebeka kunye nezinye izalathisi.

Uvavanyo olungonakalisiyo: Ukuba intsimbi enomfanekiso we-H ifuna uvavanyo olungonakalisiyo, kufuneka ivavanywe ngokuhambelana nemigangatho efanelekileyo kunye neemfuno zoku-odola ukuqinisekisa ukuba umgangatho wayo wangaphakathi ulungile.

Ukupakishwa kunye nokumakishwa: Ukupakishwa kunye nokumakishwa kwentsimbi enomfanekiso we-H kufuneka kuhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola ukuze kube lula ukuthuthwa kunye nokugcinwa.

Ngamafutshane, ezi mfuno zingasentla kufuneka ziqwalaselwe ngokupheleleyo xa kuhlolwa intsimbi enomfanekiso we-H ukuqinisekisa ukuba umgangatho wayo uyahlangabezana nemigangatho efanelekileyo kunye neemfuno zoku-odola, kunye nokubonelela abasebenzisi ngeemveliso zentsimbi enomfanekiso we-H ezilungileyo.

UKUPAKISHA NOKUTHUMELA

Ukupakishwa kunye nokukhuselwa:

Ukupakishwa kudlala indima ebalulekileyo ekukhuseleni umgangatho wentsimbi ye-ASTM A36 H beam ngexesha lokuthuthwa nokugcinwa kwayo. Izinto ezisetyenzisiweyo mazibotshwe kakuhle, kusetyenziswa imitya okanye iibhendi ezinamandla aphezulu ukuthintela intshukumo kunye nomonakalo onokubakho. Ukongeza, kufuneka kuthathwe amanyathelo okukhusela intsimbi ekuchaphazelweni kukufuma, uthuli, kunye nezinye izinto ezingqongileyo. Ukusonga iibhanti ngezinto ezimelana nemozulu, ezifana neplastiki okanye ilaphu elingangeni manzi, kunceda ukukhusela ekungcoleni nasekugqwaleni.

Ukulayisha nokukhusela ukuthutha:

Ukulayisha nokubopha intsimbi epakishiweyo kwisithuthi sokuthutha kufuneka kwenziwe ngononophelo. Ukusebenzisa izixhobo zokuphakamisa ezifanelekileyo, ezifana neeforklift okanye iicrane, kuqinisekisa inkqubo ekhuselekileyo nesebenzayo. Imiqadi kufuneka isasazwe ngokulinganayo kwaye ilungelelaniswe ngokufanelekileyo ukuthintela nawuphi na umonakalo wesakhiwo ngexesha lokuthuthwa. Nje ukuba ilayishwe, ukubopha imithwalo ngemiqobo efanelekileyo, njengeentambo okanye amatyathanga, kuqinisekisa uzinzo kwaye kuthintela ukushukuma.

UKUTYELELA KWABATHENGI

FAQ

1. Ndingayifumana njani ikowuteshini kuwe?

Ungasishiyela umyalezo, kwaye siza kuphendula yonke imiyalezo ngexesha elifanelekileyo.

2. Ngaba uza kuzihambisa iimpahla ngexesha elifanelekileyo?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni ophezulu kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3. Ndingafumana iisampulu ngaphambi kokuba ndi-odole?

Ewe, ewe. Ngokwesiqhelo iisampulu zethu zisimahla, singazivelisa ngeesampulu zakho okanye ngemizobo yobugcisa.

4. Ithini imiqathango yakho yokuhlawula?

Ixesha lethu lokuhlawula eliqhelekileyo yidiphozithi ye-30%, kwaye intsalela ihambelana ne-B/L. EXW, FOB, CFR, CIF.

5. Ngaba uyayamkela into yokuhlolwa ngumntu wesithathu?

Ewe siyamkela ngokupheleleyo.

6. Siyithemba njani inkampani yakho?

Siziingcali kwishishini lentsimbi kangangeminyaka emininzi njengomthengisi wegolide, ikomkhulu likwiphondo laseTianjin, samkelekile ukuphanda ngazo zonke iindlela, nangayiphi na indlela.