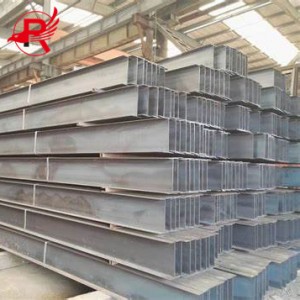

I-ASTM H-Shaped Steel H Beam | I-H-Beam Eshushu Ejikeleziweyo yeeKholamu zeNsimbi kunye namaCandelo

Umqadi we-ASTM A36 Hluhlobo lomqadi wentsimbi yolwakhiwo owenziwe ngentsimbi yekhabhoni, into esetyenziswa kakhulu neguquguqukayo eyaziwa ngamandla ayo aphezulu kunye nokuqina kwayo. Ii-H-beams zibonakaliswa ngesimo sazo esahlukileyo se-"H", esinika amandla angcono okuthwala umthwalo kunye nenkxaso kwizicelo ezahlukeneyo zokwakha kunye nobunjineli. Ngeempawu zayo eziphezulu zokwakha, i-H-beam yentsimbi yekhabhoni isetyenziswa kakhulu ekwakheni izakhiwo, iibhulorho, kunye nezinye iiprojekthi zeziseko zophuhliso. Ibonelela ngesisombululo esingabizi kakhulu nesithembekileyo sokwenza izakhelo eziqinileyo nezizinzileyo, nto leyo eyenza ukuba ibe lukhetho oludumileyo kushishino lokwakha. Amandla angaphakathi kunye nokudityaniswa kwentsimbi yekhabhoni kuphucula ngakumbi ukufaneleka kwayo kwizicelo zezakhiwo ezinzima, okwenza ii-H-beams zibe lukhetho olukhethwayo kwiinjineli kunye nabakhi abafuna izixhobo zokwakha ezithembekileyo nezisebenzayo.

Iinkcukacha ze-a yentsimbi eqengqelekayo eshushu zihlala ziquka ezi nkcukacha zilandelayo:

Ubukhulu: Ubungakanani kunye nobukhulu be-H-Beam, njengobude, ububanzi, kunye nobukhulu, buchazwe ngokweemfuno zeprojekthi.

Iimpawu ezinqamlezileyo: Iimpawu eziphambili ze-H-Beam ziquka indawo, umzuzu wokungakhathali, i-section modulus, kunye nobunzima ngobude beyunithi nganye. Ezi mpawu zibalulekile ekubaleni uyilo lwesakhiwo kunye nokuzinza kwenqwaba.

INKQUBO YOKUVELISA IMVELISO

1. Ukulungiselela kwangaphambili: kubandakanya ukuthengwa kwezinto eziluhlaza, ukuhlolwa komgangatho kunye nokulungiswa kwezinto. Izinto eziluhlaza zihlala ziyintsimbi enyibilikisiweyo eyenziwe ngokwenza isinyithi esifubeni segrafitisation esikumgangatho ophezulu okanye ukwenza isinyithi esifubeni sombane, esifakwa kwimveliso emva kokuhlolwa komgangatho.

2. Ukunyibilikisa: Galela intsimbi enyibilikisiweyo kwi-converter uze wongeze intsimbi yentsimbi okanye yehagu efanelekileyo ukuze kwenziwe intsimbi. Ngexesha lenkqubo yokwenza intsimbi, umxholo wekhabhoni kunye nobushushu bentsimbi enyibilikisiweyo kulawulwa ngokulungelelanisa umthamo we-graphitizing agent kunye nokuvuthela ioksijini kwi-oven.

3. I-billet yokuphosa eqhubekayo: I-billet yokwenza intsimbi igalelwa kumatshini wokuphosa oqhubekayo, kwaye amanzi aphuma kumatshini wokuphosa oqhubekayo afakwa kwi-crystallizer, okuvumela intsimbi enyibilikisiweyo ukuba iqine kancinci kancinci ukuze yenze i-billet.

4. Ukuqengqeleka okushushu: I-billet eqhubekayo yokuphosa iqengqeleka ngokushushu kwiyunithi yokuqengqeleka okushushu ukuze ifikelele kubungakanani obuchaziweyo kunye nemilo yejiyometri.

5. Ukuqengqeleka okugqityiweyo: I-billet eqengqelekayo eshushu igqityiwe ukuqengqeleka, kwaye ubungakanani kunye nokuma kwe-billet kwenziwa kube ngokuchanekileyo ngokulungelelanisa iiparameter ze-rolling mill kunye nokulawula amandla okuqengqeleka.

6. Ukupholisa: Intsimbi egqityiweyo iyapholiswa ukuze kuncitshiswe ubushushu kwaye kulungiswe ubukhulu kunye neempawu.

7. Ukuhlolwa komgangatho kunye nokupakishwa: Ukuhlolwa komgangatho weemveliso ezigqityiweyo kunye nokupakishwa ngokweemfuno zobungakanani kunye nobungakanani.

UBUKHULU BEMVELISO

| Iimveliso | Umqadi we-H oQokelelweyo oshushu |

| Indawo yemvelaphi | IHebei, eTshayina |

| Ibanga | Q235B/SS400/Q355B/S235JR/S355JR |

| Umgangatho | I-ASTM / AISI / JIS / EN / DIN |

| Ubungakanani | Ububanzi bewebhu:100-912mm |

| Ububanzi beFlange:50-302mm | |

| Ubukhulu bewebhu: 5-18mm | |

| Ubukhulu beFlange: 7-34mm | |

| I-alloy okanye Hayi | I-non-Alloy |

| Ezobugcisa | ebandayo okanye eshushu eqengqelekayo |

| Inkonzo Yokucubungula | Ukugoba, Ukuwelda, Ukubethela, Ukusika |

| Ixesha lokuzisa | Iintsuku ezingama-31-45 |

| Ubude | 1-12m |

| Uku-invoyisi | ngobunzima bethiyori |

| Isicelo | isakhiwo sesakhiwo kunye nolwakhiwo lobunjineli |

| Intlawulo | T/T; |

| Ubungakanani be-H Beam | ||||

| Ububanzi bewebhu (mm) | Ububanzi beFlange (mm) | Ubukhulu bewebhu (mm) | Ubukhulu beFlange (mm) | Ubunzima bethiyori (kg/m) |

| 100 | 50 | 5 | 7 | 9.54 |

| 100 | 100 | 6 | 8 | 17.2 |

| 125 | 60 | 6 | 8 | 13.3 |

| 125 | 125 | 6.5 | 9 | 23.8 |

| 150 | 75 | 5 | 7 | 14.3 |

| 148 | 100 | 6 | 9 | 21.4 |

| 150 | 150 | 7 | 10 | 31.9 |

| 175 | 90 | 5 | 8 | 18.2 |

| 175 | 175 | 7.5 | 11 | 40.4 |

| 194 | 150 | 6 | 9 | 31.2 |

| 198 | 99 | 4.5 | 7 | 18.5 |

| 200 | 100 | 5.5 | 8 | 21.7 |

| 200 | 200 | 8 | 12 | 50.5 |

| 200 | 204 | 12 | 12 | 56.7 |

| 244 | 175 | 7 | 11 | 44.1 |

| 248 | 124 | 5 | 8 | 25.8 |

| 250 | 125 | 6 | 9 | 29.7 |

| 250 | 250 | 9 | 14 | 72.4 |

| 250 | 255 | 14 | 14 | 82.2 |

| 294 | 200 | 8 | 12 | 57.3 |

| 294 | 302 | 12 | 12 | 85 |

| 298 | 149 | 5.5 | 8 | 32.6 |

| 300 | 150 | 6.5 | 9 | 37.3 |

| 300 | 300 | 10 | 15 | 94.5 |

| 300 | 305 | 15 | 15 | 106 |

| 340 | 250 | 9 | 14 | 79.7 |

| 344 | 348 | 10 | 16 | 115 |

| 346 | 174 | 6 | 9 | 41.8 |

| 350 | 175 | 7 | 11 | 50 |

| 350 | 350 | 12 | 19 | 137 |

| 388 | 402 | 15 | 15 | 141 |

| 390 | 300 | 10 | 16 | 107 |

| 394 | 398 | 11 | 18 | 147 |

| 396 | 199 | 7 | 11 | 56.7 |

| 400 | 200 | 8 | 13 | 66 |

| 400 | 400 | 13 | 21 | 172 |

| 400 | 408 | 21 | 21 | 197 |

| 414 | 405 | 18 | 28 | 233 |

| 428 | 407 | 20 | 35 | 284 |

| 440 | 300 | 11 | 18 | 124 |

| 446 | 199 | 8 | 12 | 66.7 |

| 450 | 200 | 9 | 14 | 76.5 |

| 458 | 417 | 30 | 50 | 415 |

| 482 | 300 | 11 | 15 | 115 |

| 488 | 300 | 11 | 18 | 129 |

| 496 | 199 | 9 | 14 | 79.5 |

| 498 | 432 | 45 | 70 | 605 |

| 500 | 200 | 10 | 16 | 89.6 |

| 506 | 201 | 11 | 19 | 103 |

| 582 | 300 | 12 | 17 | 137 |

| 588 | 300 | 12 | 20 | 151 |

| 594 | 302 | 14 | 23 | 175 |

| 596 | 199 | 10 | 15 | 95.1 |

| 600 | 200 | 11 | 17 | 106 |

| 606 | 201 | 12 | 20 | 120 |

| 692 | 300 | 13 | 20 | 166 |

| 700 | 300 | 12 | 24 | 185 |

| 792 | 300 | 14 | 22 | 191 |

| 800 | 300 | 14 | 26 | 210 |

| 890 | 299 | 15 | 23 | 213 |

| 900 | 300 | 16 | 28 | 243 |

| 912 | 302 | 18 | 34 | 286 |

IINZUZO

Ezinye iimpawu kunye neempawu zentsimbi yekhabhoniUmqadi we-ASTM A370 H:

- Yomelele kwaye ihlala ixesha elide: Intsimbi yekhabhoni yaziwa ngamandla ayo aphezulu kunye nokuqina kwayo, okwenza ii-H-beams zikwazi ukuxhasa imithwalo enzima kunye nokubonelela ngozinzo lwesakhiwo.

- Iyaguquguquka: Ii-H-beams ezenziwe ngentsimbi yekhabhoni zinokuguquguquka kwaye zingasetyenziswa kwiiprojekthi ezahlukeneyo zokwakha, kubandakanya izakhelo zokwakha, iibhulorho, kunye nezinye izakhiwo.

- Umthamo ofanelekileyo wokuthwala umthwalo: Imilo eyahlukileyo ye-H yomqadi inika amandla okuthwala umthwalo ngokufanelekileyo, nto leyo eyenza ukuba ifaneleke ukuxhasa iintlobo ezahlukeneyo zezakhiwo.

- Ezoqoqosho:Umqadi we-ASTM A572 Hzibonelela ngesisombululo esingabizi kakhulu kwiiprojekthi zokwakha nezokwakha ngenxa yokufumaneka kwezinto kunye nokufikeleleka kwazo.

- Iyashibilika: Intsimbi yekhabhoni inokushibilika lula, okuvumela ukwenziwa kwee-H-beams ezenzelwe wena ukuhlangabezana neemfuno ezithile zeprojekthi.

IPROJEKTHI

Inkampani yethu inamava eminyaka emininzi kurhwebo lwangaphandle lwee-H-beams. Isixa sisonke see-H-beams ezithunyelwa eKhanada ngeli xesha singaphezulu kwe-8,000,000 yeetoni. Umthengi uza kuhlola iimpahla ezikwifektri. Nje ukuba iimpahla ziphumelele uhlolo, intlawulo iya kwenziwa kwaye ithunyelwe. Ukususela oko kwaqala ukwakhiwa kwale projekthi, inkampani yethu icwangcise ngononophelo isicwangciso semveliso kwaye yaqokelela ukuhamba kwenkqubo ukuqinisekisa ukuhanjiswa ngexesha elifanelekileyo kweprojekthi yentsimbi enomfanekiso we-H. Ekubeni isetyenziswa kwizakhiwo ezinkulu zefektri, iimfuno zokusebenza kweemveliso zentsimbi enomfanekiso we-H ziphezulu kunokumelana nokugqwala kwentsimbi enomfanekiso we-H yeqonga leoyile. Ke ngoko, inkampani yethu iqala kumthombo wemveliso kwaye yonyusa ulawulo lokwenza intsimbi, ukuphoswa okuqhubekayo kunye neenkqubo ezinxulumene nokuqengqeleka. Yomeleza umgangatho weemveliso zeenkcukacha ezahlukeneyo ukuze zilawulwe ngokufanelekileyo kuzo zonke iinkalo, ukuqinisekisa izinga lokupasa le-100% leemveliso ezigqityiweyo. Ekugqibeleni, umgangatho wokucubungula wentsimbi enomfanekiso we-H waqatshelwa ngabathengi ngazwi linye, kwaye intsebenziswano yexesha elide kunye neenzuzo zamacala omabini zafezekiswa ngokusekelwe ekuthembekeni.

UHLOLO LWEMVELISO

Kwezinto eziqhelekileyoUmqadi we-ASTM A6 H, ukuba umxholo wekhabhoni uphakathi kwe-0.4% ukuya kwi-0.7%, kwaye iimfuno zepropathi yoomatshini aziphezulu kakhulu, ukulungelelanisa kungasetyenziswa njengonyango lokugqibela lobushushu. Okokuqala, kufuneka kuveliswe iintsika zentsimbi ezinemilo enqamlezileyo. Emva kokwahlulwahlulwa komsebenzi kumzi-mveliso, emva koko ziyahlanganiswa, zilinganiswe, kwaye zihlolwe ukuqinisekisa ukuba iimveliso zifanelekile kwaye emva koko zithuthwe ziye kwindawo yokwakha ukuze zifakwe ii-splicing. Ngexesha lenkqubo yokufakelwa ii-splicing, ukufakwa kwee-splicing kufuneka kwenziwe ngokuhambelana neenkqubo ezifanelekileyo. , Kuphela ngale ndlela umgangatho wemveliso unokuqinisekiswa ngokufanelekileyo. Emva kokuba ukufakwa kugqityiwe, iziphumo zokugqibela zokufakwa kufuneka zihlolwe. Emva kokuhlolwa, amaza e-ultrasonic kufuneka asetyenziswe ukwenza uvavanyo olungonakalisiyo lwangaphakathi, ukuze iziphene ezibangelwe ngexesha lokuhlanganiswa zisuswe ngokufanelekileyo. Ukongeza, ukucubungula iintsika ezinqamlezileyo nako kuyafuneka. Ngexesha lokufakwa kwesakhiwo sentsimbi, kufuneka kuqala ukhethe i-annotation eqhelekileyo, uvale inethi yokulawula, uze wenze umlinganiselo othe nkqo wokuphakama kwekholamu ephezulu. Emva koko, ukufuduka komphezulu wekholamu kunye nesakhiwo sentsimbi kufuneka kucutshungulwe ukuze kuguqulwe kakhulu, kwaye emva koko iziphumo ezithe tyaba kakhulu kunye neziphumo zokuhlolwa kwekholamu esezantsi zicutshungulwe ngokupheleleyo. Ukucutshungulwa kweenyawo ezixineneyo kufuneka kwenziwe emva kokuba indawo yekholamu yentsimbi imiselwe. Ngokuhlalutya idatha yokucubungula, ukuma kwekholamu yentsimbi kuyalungiswa kwakhona. Emva kokuba ukufakwa kugqityiwe, iirekhodi zokulinganisa kufuneka zihlolwe kwaye iingxaki zokuwelda kufuneka zihlolwe. Ukongeza, ukuvalwa kweendawo zokulawula kufuneka kuhlolwe kwakhona. Okokugqibela, umzobo wedatha yokulawula kwangaphambili kwekholamu yentsimbi esezantsi kufuneka udwetshwe.

ISICELO

Ii-H-beams zentsimbi yolwakhiwo zisetyenziswa kakhulu kwiindlela ezahlukeneyo zokwakha nezobunjineli ngenxa yamandla azo, ukuguquguquka kwazo, kunye nokukwazi kwazo ukuthwala umthwalo. Ezinye zeendlela eziqhelekileyo zokusetyenziswa kwee-H-beams zentsimbi yolwakhiwo ziquka:

1. Ulwakhiwo lwesakhiwo: Ii-H-beams zihlala zisetyenziswa njengeenkxaso zesakhiwo kulwakhiwo lwesakhiwo, kuquka neekholamu, iibhama, kunye neenkxaso zophahla. Zibonelela ngesakhelo esomeleleyo kwizakhiwo zorhwebo kunye nezokuhlala.

2. Ukwakhiwa kwebhulorho: Ii-H-beams zizinto ezibalulekileyo ekwakheni iibhulorho, apho zisetyenziselwa ukuxhasa ubunzima bedekhi yebhulorho kwaye ziququzelele ukusasazwa kwemithwalo kulo lonke ulwakhiwo.

3. Izakhiwo zemizi-mveliso: Ii-H-beams zidlala indima ebalulekileyo ekuxhaseni izixhobo ezinzima, oomatshini, kunye neziseko zophuhliso kwizakhiwo zoshishino ezifana nezityalo zokuvelisa, iindawo zokugcina impahla, kunye namaziko okuhambisa izinto.

4. Iiprojekthi zeziseko zophuhliso: Ii-H-beams zentsimbi yesakhiwo zisetyenziswa ekwakhiweni kweeprojekthi zeziseko zophuhliso ezifana neendlela ezinkulu, oololiwe, kunye neetonela, apho amandla azo okuthwala imithwalo ayimfuneko ekuxhaseni iindawo ezinkulu kunye nemithwalo enzima.

5. Ukugcina iindonga kunye nokufaka iindonga: Ii-H-beams zisetyenziswa njengezinto ezisisiseko kwiinkqubo zokugcina iindonga kunye nokufaka iindonga, zibonelela ngozinzo lwesakhiwo kunye nenkxaso yokugcina umhlaba kunye nokuzinzisa.

6. Ukusetyenziswa kwezakhiwo: Ukongeza kwiindlela ezisetyenziswa ngayo kwizakhiwo, ii-H-beams zikwasetyenziswa kwiindlela zokwakha ukwenza izinto ezibonakalayo ezikhethekileyo, ezifana nee-beams eziveziweyo kunye neempawu ezintle kwizakhiwo zanamhlanje.

UKUPAKISHA NOKUTHUMELA

Ukupakisha:

Beka iimfumba zamaphepha ngokuqinileyo: LungisaUmqadi we-ASTM A992 Hkwinqwaba ecocekileyo nezinzileyo, ukuqinisekisa ukuba zilungelelaniswe kakuhle ukuthintela naluphi na ungazinzi. Sebenzisa intambo okanye ibhandeji ukuqinisa inqwaba kwaye uthintele ukushukuma ngexesha lokuthuthwa.

Sebenzisa izinto zokukhusela ukupakisha: Songa inqwaba yeengqokelela zamaphepha ngezinto ezingangenisi manzi, ezifana neplastiki okanye iphepha elingangeni manzi, ukuze uzikhusele ekuchatshazelweni ngamanzi, ukufuma, kunye nezinye izinto ezingqongileyo. Oku kuya kunceda ukuthintela ukugqwala nokubola.

Ukuhambisa ngenqanawe:

Khetha indlela efanelekileyo yokuthutha: Ngokuxhomekeke kubungakanani kunye nobunzima beenqwaba zeeshiti, khetha indlela efanelekileyo yokuthutha, njengeelori ezisicaba, iikhonteyina, okanye iinqanawa. Cinga ngezinto ezifana nomgama, ixesha, iindleko, kunye nazo naziphi na iimfuno zomthetho zokuthutha.

Sebenzisa izixhobo zokuphakamisa ezifanelekileyo: Ukuze ulayishe kwaye ukhuphe iinqwaba zesinyithi ezimile okwe-U, sebenzisa izixhobo zokuphakamisa ezifanelekileyo ezifana neekhreyini, iifolokhwe, okanye iiloja. Qinisekisa ukuba izixhobo ezisetyenzisiweyo zinamandla aneleyo okuphatha ubunzima beenqwaba zeshiti ngokukhuselekileyo.

Qinisa umthwalo: Qinisa ngokufanelekileyo inqwaba yeeshiti ezipakishwe kwisithuthi sokuthutha usebenzisa intambo, i-bracing, okanye ezinye iindlela ezifanelekileyo zokuthintela ukushukuma, ukutyibilika, okanye ukuwa ngexesha lokuhamba.

AMANDLA ENKAMPANI

Yenziwe eTshayina, inkonzo yodidi oluphezulu, umgangatho ophezulu, idume kwihlabathi liphela

1. Isiphumo sesikali: Inkampani yethu inekhonkco elikhulu lokubonelela ngempahla kunye nomzi-mveliso omkhulu wentsimbi, ifikelela kwiziphumo zesikali kwezothutho kunye nokuthengwa kwempahla, kwaye iba yinkampani yentsimbi edibanisa imveliso kunye neenkonzo.

2. Ukwahluka kwemveliso: Ukwahluka kwemveliso, nayiphi na intsimbi oyifunayo ingathengwa kuthi, ikakhulu ibandakanya izakhiwo zentsimbi, iireyile zentsimbi, iipali zeshiti zentsimbi, izibiyeli ze-photovoltaic, intsimbi yetshaneli, iikhoyili zesinyithi zesilicon kunye nezinye iimveliso, nto leyo eyenza ukuba iguquguquke ngakumbi Khetha uhlobo lwemveliso oyifunayo ukuhlangabezana neemfuno ezahlukeneyo.

3. Ubonelelo oluzinzileyo: Ukuba nomgca wemveliso ozinzileyo kunye nochungechunge lobonelelo kunokubonelela ngobonelelo oluthembekileyo ngakumbi. Oku kubaluleke kakhulu kubathengi abafuna intsimbi eninzi.

4. Impembelelo yophawu: Banempembelelo ephezulu yophawu kunye nemarike enkulu

5. Inkonzo: Inkampani enkulu yentsimbi edibanisa ukwenziwa ngokwezifiso, uthutho kunye nemveliso

6. Ukhuphiswano lwamaxabiso: ixabiso elifanelekileyo

*Thumela i-imeyile ku[i-imeyile ikhuselwe]ukuze ufumane ikowuteshini yeeprojekthi zakho

FAQ

1. Ndingayifumana njani ikowuteshini kuwe?

Ungasishiyela umyalezo, kwaye siza kuphendula yonke imiyalezo ngexesha elifanelekileyo.

2. Ngaba uza kuzihambisa iimpahla ngexesha elifanelekileyo?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni ophezulu kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3. Ndingafumana iisampulu ngaphambi kokuba ndi-odole?

Ewe, ewe. Ngokwesiqhelo iisampulu zethu zisimahla, singazivelisa ngeesampulu zakho okanye ngemizobo yobugcisa.

4. Ithini imiqathango yakho yokuhlawula?

Ixesha lethu lokuhlawula eliqhelekileyo yidiphozithi ye-30%, kwaye intsalela imele i-B/L.

5. Ngaba uyayamkela into yokuhlolwa ngumntu wesithathu?

Ewe siyamkela ngokupheleleyo.

6. Siyithemba njani inkampani yakho?

Siziingcali kwishishini lentsimbi kangangeminyaka emininzi njengomthengisi wegolide, ikomkhulu likwiphondo laseTianjin, samkelekile ukuphanda ngazo zonke iindlela, nangayiphi na indlela.