Inkonzo yokuWelda yeSinyithi yeNsimbi eyenziwe ngokwezifiso kunye neNkonzo yokuSika iLaser Ukunyathela iinxalenye zeSheet Metal Processing

Iinkcukacha zeMveliso

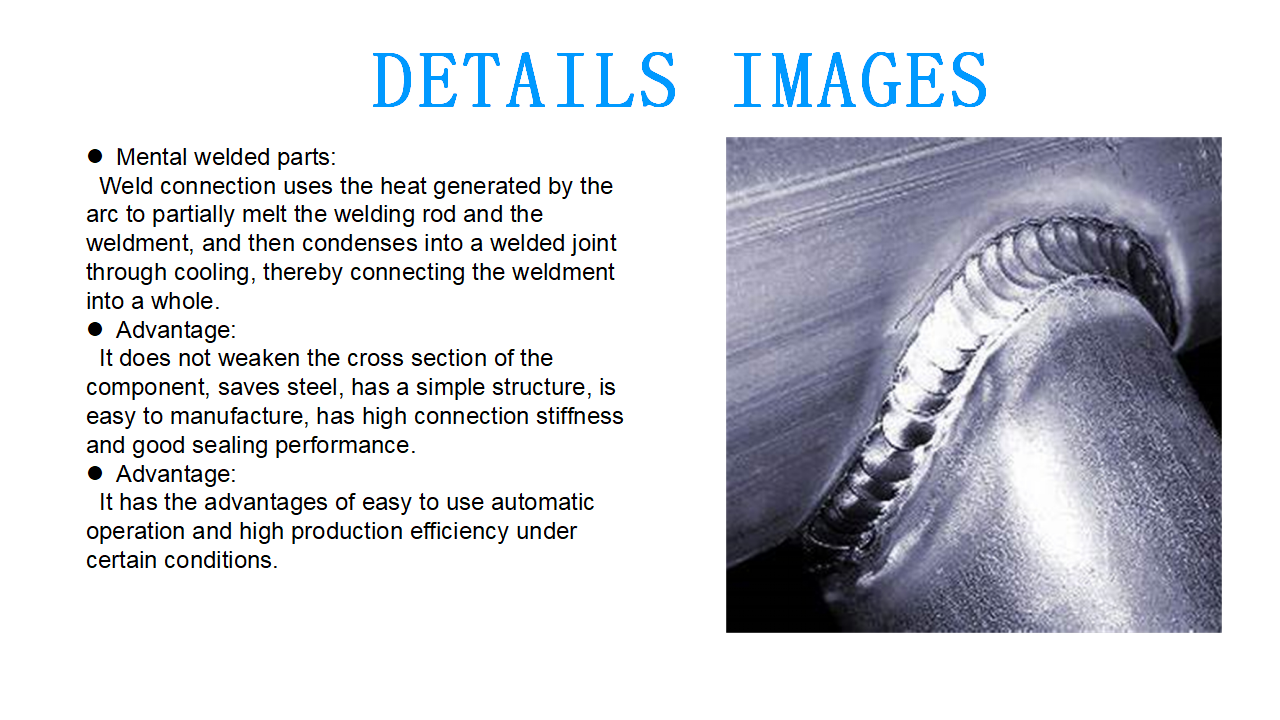

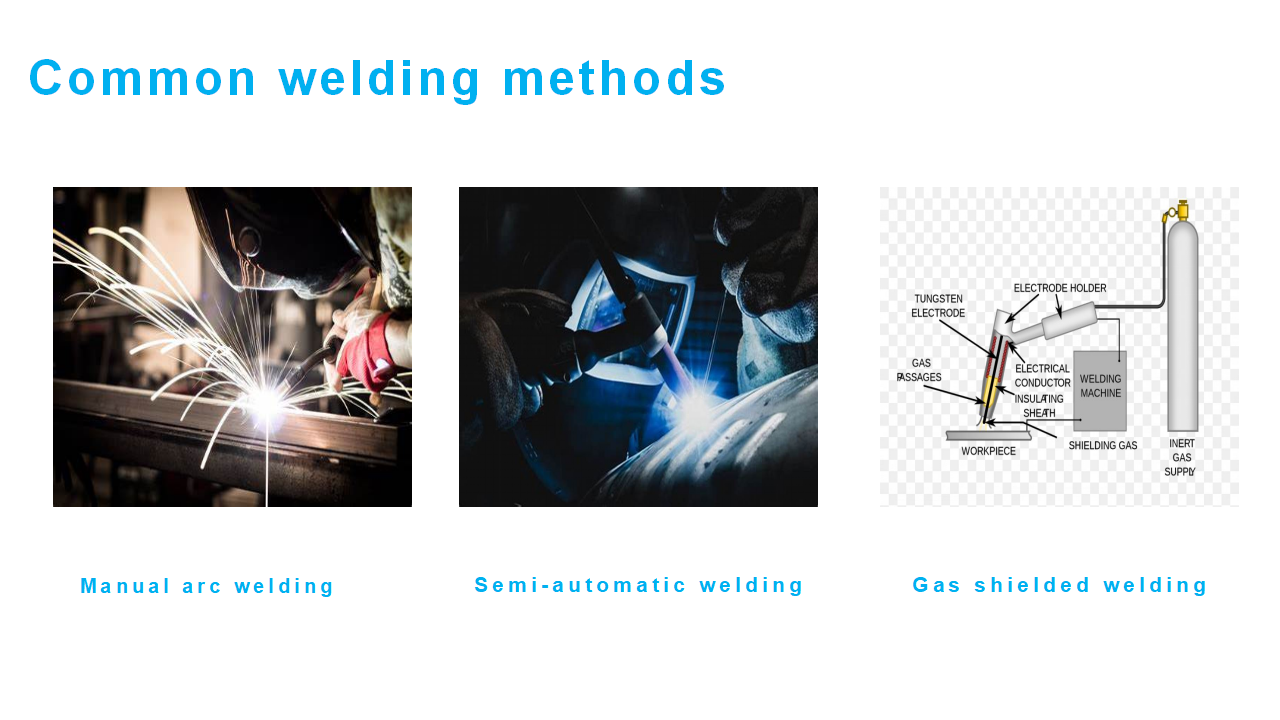

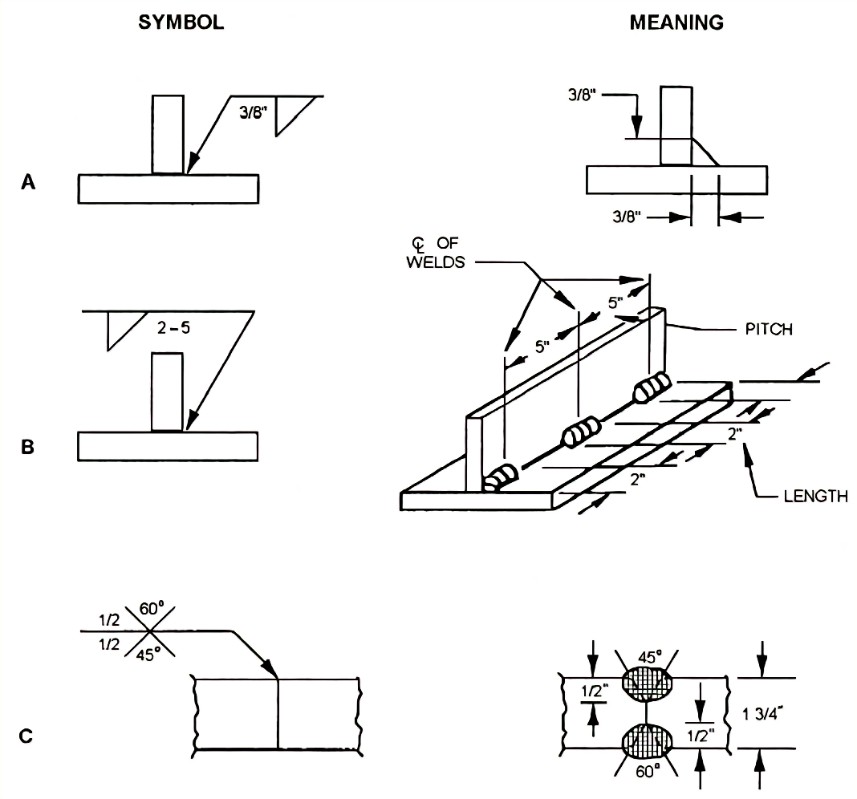

Iindlela eziqhelekileyo zokuwelda ziquka ukuwelda nge-arc, ukuwelda nge-gas shielded, ukuwelda nge-laser, njl. Ukuwelda nge-arc yenye yezona ndlela zisetyenziswa kakhulu zokuwelda. Le arc ivelisa ubushushu obuphezulu ukuze inyibilikise izinto zokuwelda. Isetyenziswa kakhulu kwizakhiwo zentsimbi, ekwakheni iinqanawa nakwezinye iindawo. Ukuwelda nge-gas shielded kusebenzisa igesi engangeniyo okanye igesi esebenzayo ukukhusela indawo yokuwelda ukuthintela i-oxidation kunye nolunye ungcoliseko. Ifanelekile ukuwelda i-aluminium alloy, intsimbi engatyiwayo kunye nezinye izinto. Ukuwelda nge-laser kusebenzisa imisebe ye-laser enamandla aphezulu ukunyibilikisa nokudibanisa izinto zokuwelda. Inezibonelelo zokuchaneka okuphezulu kunye nendawo encinci echaphazeleka bubushushu, kwaye ifanelekile ukuwelda ngokuchanekileyo kunye nemveliso ezenzekelayo.

Ukulungiswa kwe-weldingIdlala indima ebalulekileyo kushishino lokuvelisa, ivumela uqhagamshelo kunye nokulungiswa kwezinto, kwaye isetyenziswa kakhulu kwi-aerospace, kwimveliso yeemoto, kubunjineli bokwakha nakwezinye iindawo. Ngophuhliso oluqhubekayo lwetekhnoloji, ukucubungula ukuwelda kukwavelisa izinto ezintsha rhoqo. Ukusetyenziswa kwetekhnoloji ephezulu efana nokuwelda nge-laser kunye nokuwelda nge-plasma arc kunika ukhetho oluninzi kunye namathuba kwishishini lokuvelisa.

Kwihlabathi lokusebenza ngesinyithi, ukwenziwa kwe-welding sisakhono esibalulekileyo esifuna ukuchaneka, ubuchule, kunye neliso elibukhali leenkcukacha. Nokuba kukudala uyilo oluntsonkothileyo okanye ukwakha izakhiwo eziqinileyo, abenzi be-welding badlala indima ebalulekileyo ekuveliseni isinyithi. Ukusuka kwi-welding eyenziwe ngezinto zobugcisa ukuya kwi-laser welding sheet metal, ubugcisa bokwenziwa kwe-welding buquka uluhlu olubanzi lweendlela kunye neenkqubo ezibalulekileyo kumashishini ahlukeneyo.

Ukuwelda okusemgangathweni yeyona nto ibalulekileyo kulo naliphi na ishishini lokuwelda eliphumelelayo. Akubandakanyi nje kuphela iinkalo zobugcisa zokuwelda kodwa kukwabandakanya nokuzibophelela ekunikezeni iziphumo ezihlala ixesha elide nezingenasiphako. Umenzi wokuwelda onobuchule uyayiqonda into yokubaluleka kokusebenzisa izixhobo ezifanelekileyo, izixhobo, kunye neendlela zokuqinisekisa umgangatho ophezulu emsebenzini wakhe. Oku kuzinikela ekugqweseni kuhlukanisa amashishini okuwelda ahloniphekileyo kwaye kuwenza athembeke kwaye athembeke kubathengi bawo.

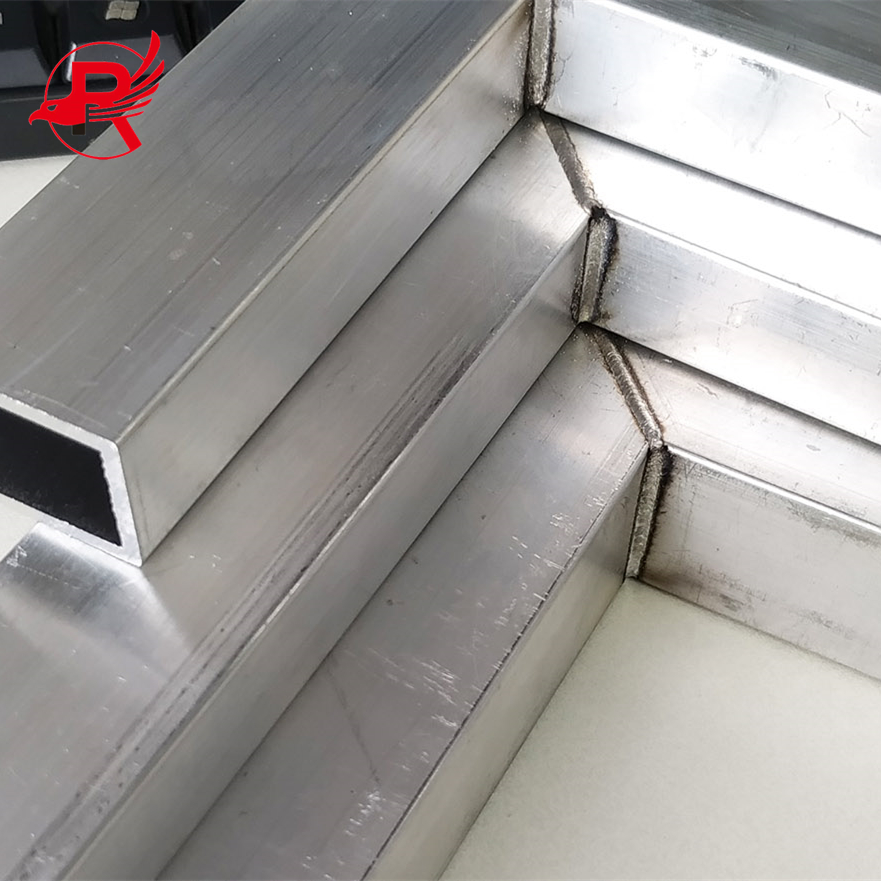

Xa kufikwa kuishiti yesinyithi yokuwelda, ukuchaneka kubalulekile. Ukukwazi ukudibanisa amaphepha esinyithi ngaphandle komthungo kufuna indibaniselwano yobuchule kunye nezixhobo ezifanelekileyo. I-laser welding sheet metal, ngakumbi, iye yathandwa kakhulu ngenxa yokukwazi kwayo ukuvelisa ii-welds ezicocekileyo nezichanekileyo ezineendawo ezincinci ezichaphazeleka bubushushu. Le ndlela iphambili iguqule inkqubo ye-sheet metal welding, ivumela ukuchaneka okukhulu kunye nokusebenza kakuhle.

Kwihlabathi leukwenziwa kwe-welding, ingqalelo kwiinkcukacha ibaluleke kakhulu. Yonke i-weld kufuneka yenziwe ngononophelo ukuqinisekisa ukuthembeka kwesakhiwo kunye nobude bayo. Nokuba kukudala ubugcisa besinyithi obukhethekileyo okanye ukwenza izinto zoshishino, isakhono kunye nobugcisa bomenzi we-welding bunokwenza umahluko omkhulu.

Njengoko iteknoloji iqhubeka ihambela phambili, ikamva lokwenziwa kweentsimbi libonakala lithembisa. Utshintsho kwizixhobo kunye neendlela zobugcisa luhlala lutyhala imida yoko kunokwenzeka kwihlabathi lokusebenza ngentsimbi. Nangona kunjalo, kukho into enye engaguqukiyo: ukubaluleka komgangatho kunye nokuchaneka kokwenziwa kweentsimbi.

Ukuqukumbela, ukwenziwa kwee-welding kukudibanisa ubugcisa nesayensi, apho ubuchule kunye nobuchule zidityaniswe khona ukuze kudalwe umsebenzi wesinyithi obalaseleyo. Ukusuka ekuwelding okugqwesileyo ukuya kwi-laserishiti yesinyithi yokuwelda, ukuzinikela kumgangatho kunye nokuchaneka kumisela umgangatho wabenzi beentsimbi kunye namashishini ngokufanayo. Njengoko eli shishini liqhubeka likhula, ubugcisa bokwenza iintsimbi buza kuqhubeka nokudlala indima ebalulekileyo ekubumbeni ihlabathi elisingqongileyo.

| Izinto eziphathekayo | Intsimbi yebhokisi/i-aluminiyamu/ithusi/intsimbi engatyiwayo/i-spcc |

| Umbala | Yenzelwe wena |

| Ukucutshungulwa | Ukusika nge-laser/Ukubetha nge-CNC/Ukugoba nge-CNC/Ukuwelda/Ukupeyinta/Ukuhlanganisa |

| Unyango lomphezulu | Ukwaleka kwamandla, i-zinc plated, i-Polishing, i-Plating, i-Brush, i-Skill-screen njl. |

| Ifomathi yoMzobo | I-CAD, i-PDF, i-SOLIDworks njl. |

| Isiqinisekiso | ISO9001:2008 CE SGS |

| Uhlolo loMgangatho | igeyiji yephini, igeyiji ye-caliper, uvavanyo lokulahla, uvavanyo lokungcangcazela, uvavanyo lomjikelo wobomi bemveliso, uvavanyo lokutshiza ngetyuwa, iprojektha, ukulinganisa okucwangcisiweyo ii-calipers zomatshini, i-micro caliper, i-thread miro caliper, i-pass meter, i-pass meter njl. |

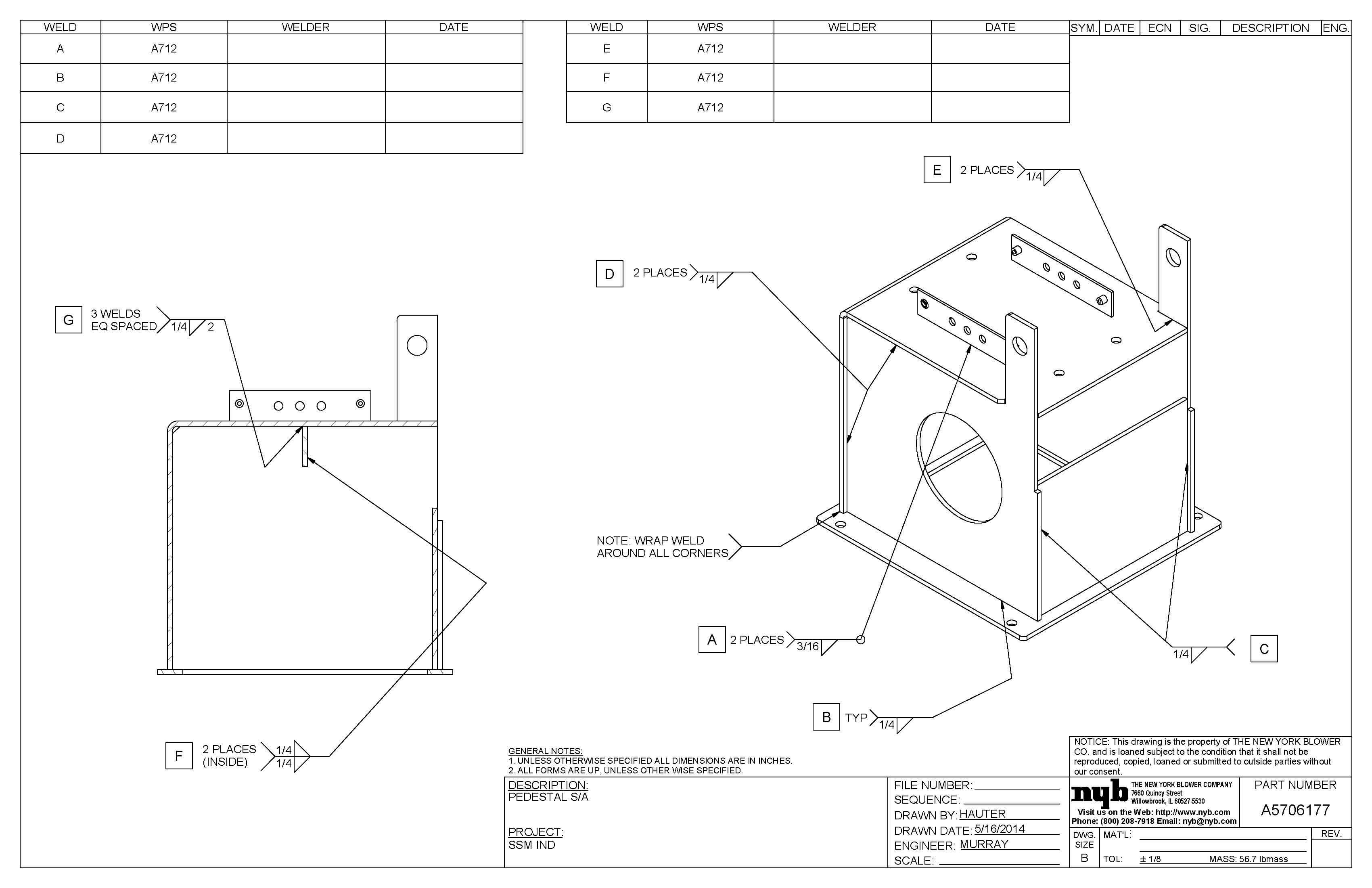

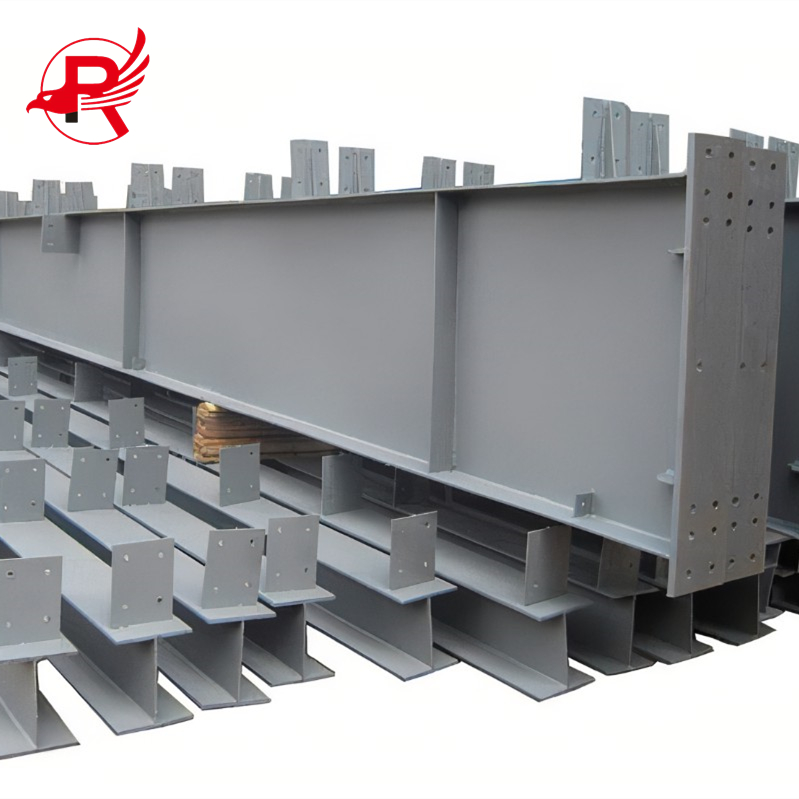

Umzekelo

Le yi-odolo esiyifumeneyo yokucubungula iinxalenye.

Siza kuvelisa ngokuchanekileyo ngokwemizobo.

| Iinxalenye ezenziwe ngomatshini ezenziwe ngokwezifiso | |

| 1. Ubungakanani | Yenzelwe wena |

| 2. Umgangatho: | Eyenzelwe wena okanye i-GB |

| 3. Izinto eziphathekayo | Yenzelwe wena |

| 4. Indawo yefektri yethu | eTianjin, eTshayina |

| 5. Ukusetyenziswa: | Ukuhlangabezana neemfuno zabathengi |

| 6. Ukwaleka: | Yenzelwe wena |

| 7. Indlela yokusebenza: | Yenzelwe wena |

| 8. Uhlobo: | Yenzelwe wena |

| 9. Imilo yeCandelo: | Yenzelwe wena |

| 10. Uhlolo: | Ukuhlolwa okanye ukuhlolwa komthengi ngumntu wesithathu. |

| 11. Ukuhanjiswa: | Isitya, Isitya Esininzi. |

| 12. Malunga noMgangatho wethu: | 1) Akukho monakalo, akukho kugoba2) Ubukhulu obuchanekileyo3) Zonke iimpahla zingajongwa ngokuhlolwa ngumntu wesithathu ngaphambi kokuba zithunyelwe |

Ukuba nje unemfuno zokulungisa imveliso yentsimbi eyenzelwe wena, singayivelisa ngokuchanekileyo ngokwemizobo. Ukuba akukho mizobo, abayili bethu baya kukwenzela uyilo oluhambelana neemfuno zakho zenkcazo yemveliso.

Umboniso wemveliso ogqityiweyo

Ukupakishwa kunye nokuthunyelwa

Iphakheji:

Siza kupakisha iimveliso ngokweemfuno zabathengi, sisebenzisa iibhokisi zomthi okanye izikhongozeli, kwaye iiprofayili ezinkulu ziya kupakisha ngqo zingenanto, kwaye iimveliso ziya kupakisha ngokweemfuno zabathengi.

Ukuhambisa ngenqanawe:

Khetha indlela efanelekileyo yokuthutha: Ngokobungakanani kunye nobunzima beemveliso ezenzelwe wena, khetha indlela efanelekileyo yokuthutha, njengelori eflethi, isitya okanye inqanawa. Cinga ngezinto ezifana nomgama, ixesha, iindleko kunye nazo naziphi na iimfuno zomthetho zokuthutha.

Sebenzisa izixhobo zokuphakamisa ezifanelekileyo: Ukuze ulayishe kwaye wothule imijelo ye-strut, sebenzisa izixhobo zokuphakamisa ezifanelekileyo ezifana ne-crane, i-forklift, okanye i-loader. Qinisekisa ukuba izixhobo ezisetyenzisiweyo zinamandla aneleyo okuphatha ngokukhuselekileyo ubunzima beenqwaba zeeshiti.

Ukukhusela Imithwalo: Zikhusele ngokufanelekileyo iimfumba zeemveliso ezenziwe ngokwezifiso kwizithuthi zokuthutha usebenzisa iintambo, izixhasi, okanye ezinye iindlela ezifanelekileyo ukuthintela ukungqubana okanye ukonakala ngexesha lokuthuthwa.

FAQ

1. Ndingayifumana njani ikowuteshini kuwe?

Ungasishiyela umyalezo, kwaye siza kuphendula yonke imiyalezo ngexesha elifanelekileyo.

2. Ngaba uza kuzihambisa iimpahla ngexesha elifanelekileyo?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni ophezulu kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3. Ndingafumana iisampulu ngaphambi kokuba ndi-odole?

Ewe, ewe. Ngokwesiqhelo iisampulu zethu zisimahla, singazivelisa ngeesampulu zakho okanye ngemizobo yobugcisa.

4. Ithini imiqathango yakho yokuhlawula?

Ixesha lethu lokuhlawula eliqhelekileyo yidiphozithi ye-30%, kwaye intsalela imele i-B/L.

5. Ngaba uyayamkela into yokuhlolwa ngumntu wesithathu?

Ewe siyamkela ngokupheleleyo.

6. Siyithemba njani inkampani yakho?

Siziingcali kwishishini lentsimbi kangangeminyaka emininzi njengomthengisi wegolide, ikomkhulu likwiphondo laseTianjin, samkelekile ukuphanda ngazo zonke iindlela, nangayiphi na indlela.