Inkonzo Yokwenziwa Kwesinyithi Ngokwesiko Ukwenziwa Kwesinyithi Ukunyathela Ukusikwa KweLaser Inxalenye Yokusika Iphepha Lesinyithi Ukwenziwa Kwesinyithi

Iinkcukacha zeMveliso

Izixhobo zentsimbi ziimveliso zoshishino okanye zabathengi ezineemilo, ubungakanani, kunye nemisebenzi ethile, ezenziwe ngentsimbi (njengentsimbi yekhabhoni, intsimbi engatyiwayo, kunye nentsimbi ye-alloy) ngeendlela ezahlukeneyo zokucubungula, kubandakanya ukubumba, ukunyathela, ukusika, ukuwelda, ukugoba, kunye nonyango lomphezulu. Zisetyenziswa kakhulu kwimveliso yoomatshini, ubunjineli bokwakha, iimoto kunye nokwakha iinqanawa, kunye nezixhobo zasekhaya.

Iimpawu eziphambili zeendawo zentsimbi kukuqina okuphezulu kunye nokumelana nempembelelo kwentsimbi, kudityaniswe nokucubungula okwenziwe ngokwezifiso ukuhlangabezana neemfuno zeemeko ezahlukeneyo. Iindidi eziqhelekileyo ziquka iindawo zoomatshini (iigiya, izihlalo zeebheringi), izinto zokwakha (izibiyeli zesakhiwo sentsimbi), iibhokisi zezixhobo, kunye nezixhobo zehardware.

iindawo ezitshisiweyo, iimveliso ezineembobo, iindawo ezigqunyiweyo, iindawo ezigobileyo, iindawo zokusika

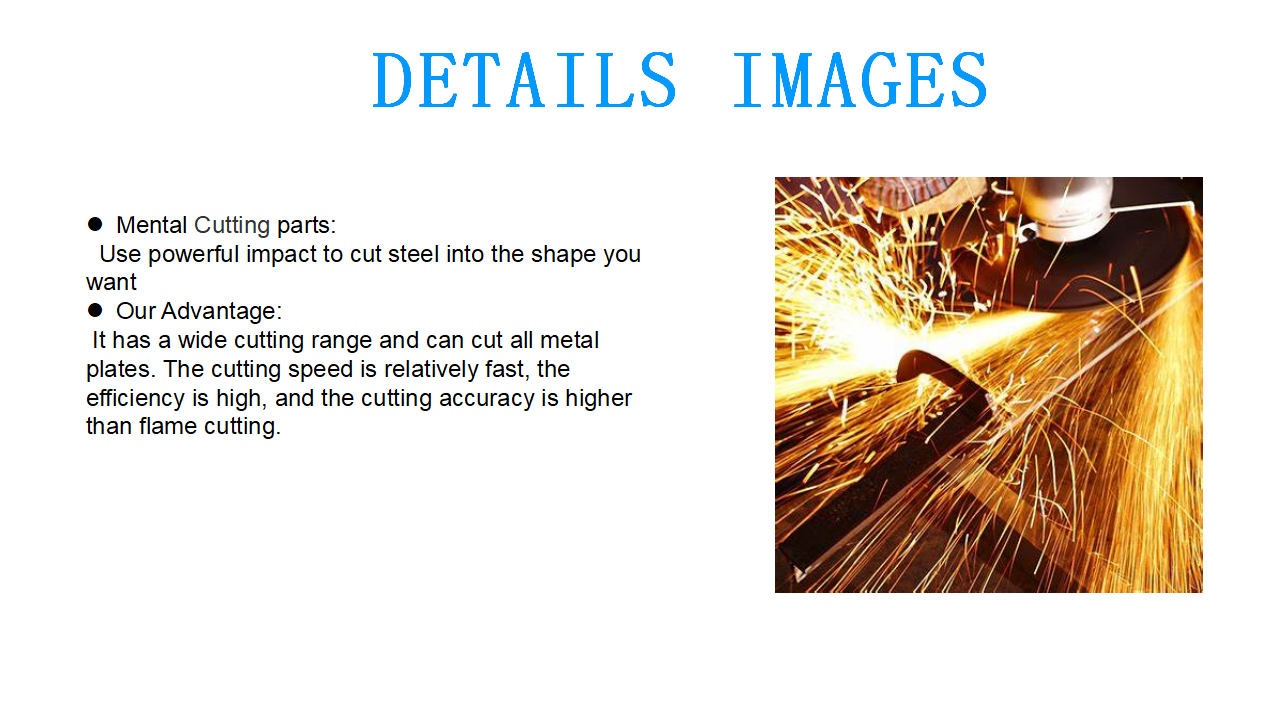

Kwishishini lokuvelisa, ukuchaneka nokusebenza kakuhle zezona zinto ziphambili ekufuneka zenziwe ukuze kuveliswe iimveliso ezikumgangatho ophezulu. Itekhnoloji yokusika isinyithi selaser iyahlangabezana ngokugqibeleleyo nale mfuno, izisa impembelelo enkulu kumacandelo ahlukeneyo afana neemoto, i-aerospace, i-elektroniki, kunye nolwakhiwo, nto leyo eguqula indlela esetyenziswa ngayo isinyithi selaphu.

Le teknoloji isebenzisa iilaser ezinamandla aphezulu ukufezekisa ukusika isinyithi ngokuchanekileyo. Ayihambelani kuphela nezinto ezahlukeneyo zesinyithi ezifana nentsimbi, i-aluminium, kunye nobhedu, kodwa ikwavumela ukucutshungulwa ngokuchanekileyo koyilo oluntsonkothileyo kunye nezakhiwo ezinemilo ekhethekileyo ngelixa inciphisa inkunkuma yezinto, nto leyo eyenza ukuba ibe sisisombululo esisebenzisekayo kwiimfuno ezahlukeneyo zokuvelisa.

Ukuchaneka okuphezulu yenye yeenzuzo zayo eziphambili: ukusika nge-laser kwenza ulawulo oluqinileyo kunye nokucutshungulwa kweenkcukacha ezincinci, kuqinisekisa ukuhlanganiswa okungenamthungo kwamacandelo. Oku kubalulekile kumashishini achanekileyo afana ne-aerospace kunye ne-elektroniki, apho nokuba ukuphambuka okuncinci kunokukhokelela ekungasebenzi kakuhle kwemveliso.

Ikwabonelela ngokusebenza kakuhle kuneendlela zemveli zokucubungula: Ngokusebenzisa itekhnoloji ye-CNC, uyilo lunokuhlelwa ngokukhawuleza kwaye luphunyezwe, lunciphise kakhulu ixesha lokufaka izixhobo, ngaloo ndlela lunciphise amaxesha okuguqula imveliso kwaye luphucule imveliso, okwenza ukuba lufaneleke ngakumbi kwiimeko zemveliso ezinomthamo omkhulu. Ngokwembono yeendleko, ukusika isinyithi nge-laser kunokufezekisa ukunciphisa iindleko zexesha elide. Okokuqala, inkunkuma yezinto ezisetyenzisiweyo encitshisiweyo inciphisa ngokuthe ngqo iindleko zezinto eziluhlaza. Okwesibini, isusa isidingo sezixhobo ezenziwe ngokwezifiso ukuvelisa izakhiwo ezintsonkothileyo, inciphisa iindleko zezixhobo kunye neenkqubo kwaye ekugqibeleni iphucule iindleko zemveliso iyonke.

Ukuguquguquka kukwaluncedo oluphambili: kuyakhululeka kwimida yezixhobo zemveli kwaye kwenza kube lula ukuvelisa kunye nokubhala iiprototypes eziguquguqukayo. Abavelisi banokuphendula ngokukhawuleza kutshintsho loyilo kwaye bavelise iibhetshi ezincinci zezinto ezenziwe ngokwezifiso ngaphandle kokufaka iindleko eziphezulu zokugunyazisa izixhobo.

Ngamafutshane, iingenelo zokusikwa kwesinyithi nge-laser kwishishini lokuvelisa zibalulekile kwaye azinakutshintshwa. Ukusebenza kwayo okubanzi ngokuchanekileyo, ukusebenza kakuhle, ulawulo lweendleko, kunye nokuguquguquka kwenza ukuba ibe sisixhobo esiphambili kumashishini alandela iindawo zesinyithi ezenziwe ngokwezifiso ezikumgangatho ophezulu. Ngokuqhubeka nokuqhubela phambili kwetekhnoloji, amandla okusikwa kwe-laser kwishishini lokuvelisa aya kukhululwa ngakumbi, anike inkxaso enkulu kwimveliso entsha kunye nophuhliso.

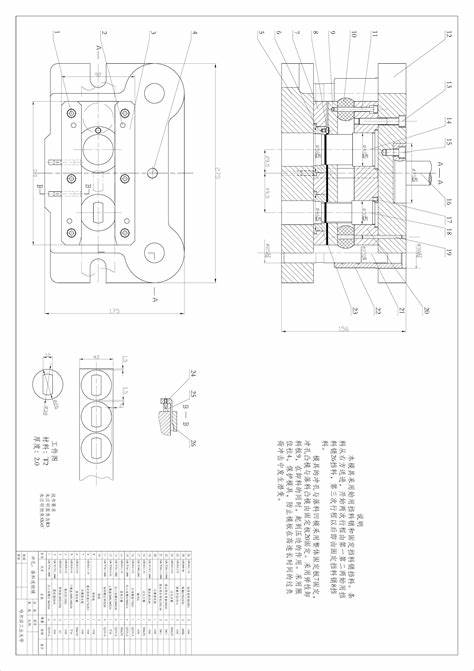

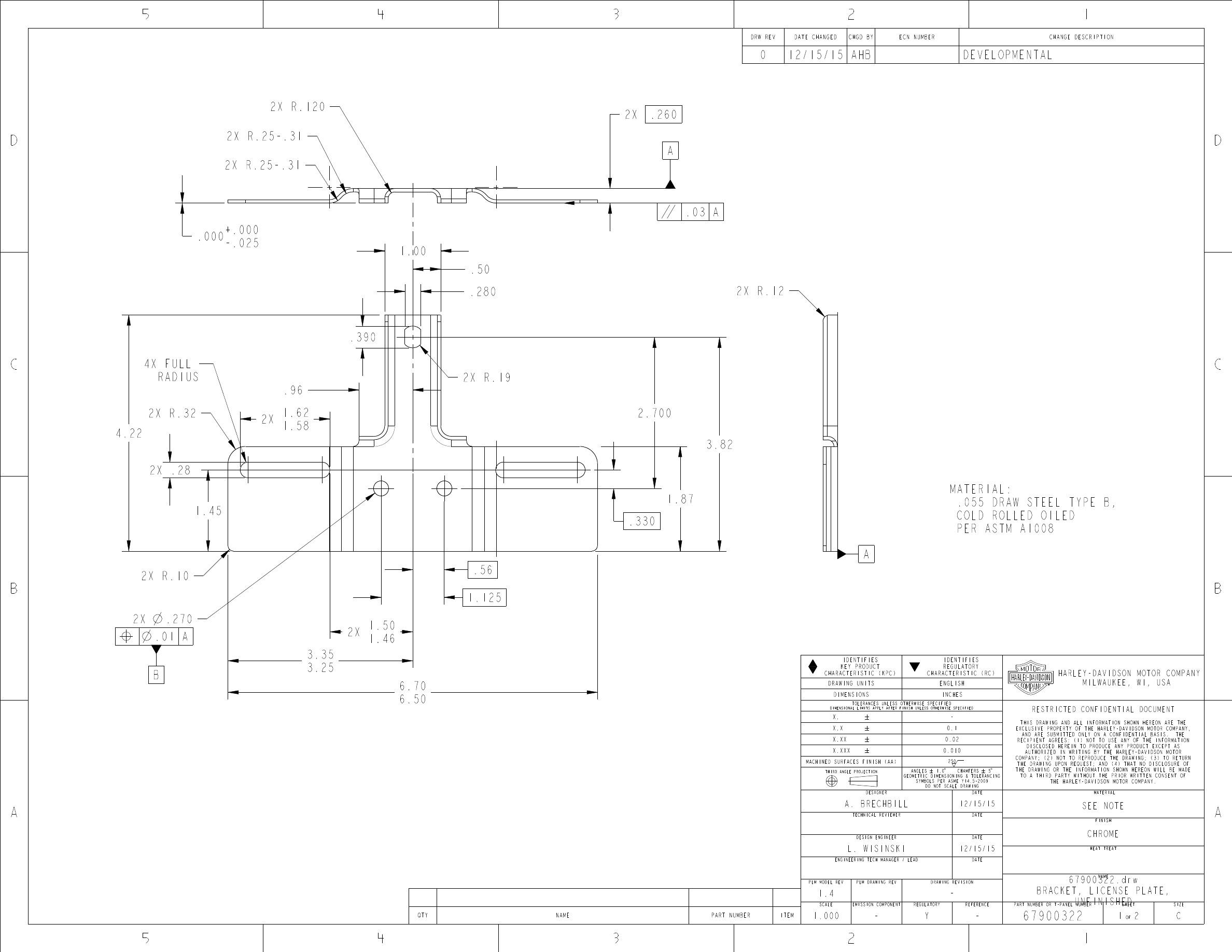

| Iinxalenye Zokwenziwa Kwesinyithi Esichanekileyo Ngokwesiko | ||||

| Isicatshulwa | Ngokwendlela odwebe ngayo (ubungakanani, izinto, ubukhulu, umxholo wokucubungula, kunye netekhnoloji efunekayo, njl.njl.) | |||

| Izinto eziphathekayo | Intsimbi yekhabhoni, intsimbi engatyiwayo, i-SPCc, i-SGCc, umbhobho, i-galvanized | |||

| Ukucutshungulwa | Ukusika nge-laser, ukugoba, ukuqhobosha, ukubhola, ukuwelda, ukwenza isinyithi, ukuhlanganisa, njl. | |||

| Unyango Lomphezulu | Ukubrasha, ukupolisha, ukufunxa, ukugquma ngepowder, ukuplata, | |||

| Ukunyamezelana | '+/-0.2mm, uhlolo lomgangatho we-QC oluyi-100% ngaphambi kokuba uhanjiswe, lunokubonelela ngefomu lokuhlolwa komgangatho | |||

| Ilogo | Ushicilelo lwesilika, uphawu lwelaser | |||

| Ubungakanani/Umbala | Yamkela ubungakanani/imibala eyenziwe ngokwezifiso | |||

| Ifomathi yoMzobo | .DWG/.DXF/.STEP/.IGS/.3DS/.STL/.SKP/.AI/.PDF/.JPG/.Draft | |||

| Isampuli yeXesha lokuFunda | Thetha ngexesha lokuhanjiswa ngokweemfuno zakho | |||

| Ukupakisha | Ngebhokisi/ibhokisi okanye ngokweemfuno zakho | |||

| Isatifikethi | I-ISO9001:SGS/TUV/ROHS | |||

Umzekelo

| Iinxalenye ezenziwe ngomatshini ezenziwe ngokwezifiso | |

| 1. Ubungakanani | Yenzelwe wena |

| 2. Umgangatho: | Eyenzelwe wena okanye i-GB |

| 3. Izinto eziphathekayo | Yenzelwe wena |

| 4. Indawo yefektri yethu | eTianjin, eTshayina |

| 5. Ukusetyenziswa: | Ukuhlangabezana neemfuno zabathengi |

| 6. Ukwaleka: | Yenzelwe wena |

| 7. Indlela yokusebenza: | Yenzelwe wena |

| 8. Uhlobo: | Yenzelwe wena |

| 9. Imilo yeCandelo: | Yenzelwe wena |

| 10. Uhlolo: | Ukuhlolwa okanye ukuhlolwa komthengi ngumntu wesithathu. |

| 11. Ukuhanjiswa: | Isitya, Isitya Esininzi. |

| 12. Malunga noMgangatho wethu: | 1) Akukho monakalo, akukho kugoba 2) Ubukhulu obuchanekileyo 3) Zonke iimpahla zingajongwa ngokuhlolwa ngumntu wesithathu ngaphambi kokuba zithunyelwe |

Umboniso weMveliso ogqityiweyo

Ukupakishwa kunye nokuthunyelwa

Ukupakishwa kunye nokuthuthwa kweendawo ezisikiweyo ngeplasma kubalulekile ukuqinisekisa umgangatho wemveliso kunye nokuhanjiswa okukhuselekileyo. Okokuqala, ngenxa yokuchaneka okuphezulu kunye nomgangatho weendawo ezisikiweyo ngeplasma, izixhobo zokupakisha ezifanelekileyo kunye neendlela zibalulekile ukuthintela umonakalo ngexesha lokuthuthwa. Iindawo ezincinci ezisikiweyo ngeplasma zinokupakishwa kwiibhokisi zefoam okanye kwiibhokisi. Iindawo ezinkulu ezisikiweyo ngeplasma zihlala zipakishwa kwiikreyithi zomthi ukuze zikhuseleke ekonakaleni ngexesha lokuthuthwa.

Ngexesha lenkqubo yokupakisha, iindawo kufuneka ziqiniswe kakuhle kwaye zigqunywe ngokweempawu zazo ukuthintela umonakalo kwimpembelelo kunye nokungcangcazela ngexesha lokuthuthwa. Kwiindawo ezisikiweyo ngeplasma ezineemilo ezingaqhelekanga, izisombululo zokupakisha ezenzelwe wena ziyafuneka ukuqinisekisa uzinzo lwazo ngexesha lokuthuthwa.

Ngexesha lokuthuthwa, kubalulekile ukukhetha iqabane elithembekileyo lezothutho ukuqinisekisa ukuhanjiswa ngokukhuselekileyo nangexesha elifanelekileyo kwezixhobo ezisikiweyo ngeplasma. Kwizinto ezithunyelwa kwamanye amazwe, kubalulekile ukuqonda imigaqo efanelekileyo yokungenisa impahla kunye nemigangatho yokuthutha yelizwe ekuyiwa kulo ukuqinisekisa ukuhanjiswa kwempahla ngendlela ethe tye kunye nokuhanjiswa kwayo.

Ngaphezu koko, kwiindawo ezisikiweyo ngeplasma ezenziwe ngezinto ezikhethekileyo okanye ezineemilo ezintsonkothileyo, iimfuno ezikhethekileyo ezifana nokufuma kunye nokukhuselwa kokugqwala kufuneka ziqwalaselwe ngexesha lokupakisha kunye nokuthuthwa ukuqinisekisa ukuba umgangatho wemveliso awuchaphazeleki.

Ngamafutshane, ukupakishwa kunye nokuthuthwa kwezinto ezisikiweyo ngeplasma zizinto ezibalulekileyo ukuqinisekisa umgangatho wemveliso kunye nokwaneliseka kwabathengi. Ucwangciso olufanelekileyo kunye nokusebenza kuyafuneka ngokubhekiselele ekukhetheni izinto zokupakisha, ukuzaliswa okusisigxina, kunye nokukhetha indlela yokuthutha ukuqinisekisa ukuba iimveliso zisiwa kubathengi ngokukhuselekileyo nangokupheleleyo.

AMANDLA ENKAMPANI

Yenziwe eTshayina, inkonzo yodidi oluphezulu, umgangatho ophezulu, idume kwihlabathi liphela

1. Isiphumo sesikali: Inkampani yethu inekhonkco elikhulu lokubonelela ngempahla kunye nomzi-mveliso omkhulu wentsimbi, ifikelela kwiziphumo zesikali kwezothutho kunye nokuthengwa kwempahla, kwaye iba yinkampani yentsimbi edibanisa imveliso kunye neenkonzo.

2. Ukwahluka kwemveliso: Ukwahluka kwemveliso, nayiphi na intsimbi oyifunayo ingathengwa kuthi, ikakhulu ibandakanya izakhiwo zentsimbi, iireyile zentsimbi, iipali zeshiti zentsimbi, izibiyeli ze-photovoltaic, intsimbi yetshaneli, iikhoyili zesinyithi zesilicon kunye nezinye iimveliso, nto leyo eyenza ukuba iguquguquke ngakumbi Khetha uhlobo lwemveliso oyifunayo ukuhlangabezana neemfuno ezahlukeneyo.

3. Ubonelelo oluzinzileyo: Ukuba nomgca wemveliso ozinzileyo kunye nochungechunge lobonelelo kunokubonelela ngobonelelo oluthembekileyo ngakumbi. Oku kubaluleke kakhulu kubathengi abafuna intsimbi eninzi.

4. Impembelelo yophawu: Banempembelelo ephezulu yophawu kunye nemarike enkulu

5. Inkonzo: Inkampani enkulu yentsimbi edibanisa ukwenziwa ngokwezifiso, uthutho kunye nemveliso

6. Ukhuphiswano lwamaxabiso: ixabiso elifanelekileyo

UKUTYELELA KWABATHENGI

FAQ

1. Ndingayifumana njani ikowuteshini kuwe?

Ungasishiyela umyalezo, kwaye siza kuphendula yonke imiyalezo ngexesha elifanelekileyo.

2. Ngaba uza kuzihambisa iimpahla ngexesha elifanelekileyo?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni ophezulu kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3. Ndingafumana iisampulu ngaphambi kokuba ndi-odole?

Ewe, ewe. Ngokwesiqhelo iisampulu zethu zisimahla, singazivelisa ngeesampulu zakho okanye ngemizobo yobugcisa.

4. Ithini imiqathango yakho yokuhlawula?

Ixesha lethu lokuhlawula eliqhelekileyo yidiphozithi ye-30%, kwaye intsalela imele i-B/L.

5. Ngaba uyayamkela into yokuhlolwa ngumntu wesithathu?

Ewe siyamkela ngokupheleleyo.

6. Siyithemba njani inkampani yakho?

Siziingcali kwishishini lentsimbi kangangeminyaka emininzi njengomthengisi wegolide, ikomkhulu likwiphondo laseTianjin, samkelekile ukuphanda ngazo zonke iindlela, nangayiphi na indlela.