Inkonzo yokusika iprofayili yesinyithi ye-meta eyenziwe ngokwezifiso

Iinkcukacha zeMveliso

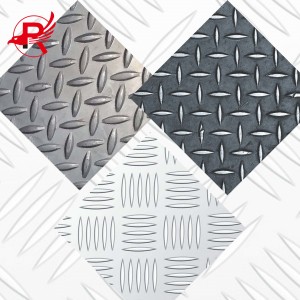

Izixhobo zentsimbi zenziwe ngentsimbi eluhlaza. Ngokusekelwe kwimizobo yabathengi, sizenzela ngokwezifiso kwaye senze iimolds ngokusekelwe kwiinkcukacha ezifunekayo, ubukhulu, izinto, kunye nonyango lomphezulu. Sinikezela ngemveliso echanekileyo, esemgangathweni ophezulu, kunye netekhnoloji ephezulu eyenzelwe iimfuno zakho. Nokuba awunayo umzobo woyilo, abayili bethu baya kuyila ngokweemfuno zakho.

Iindidi eziphambili zeenxalenye ezicutshungulwayo:

iindawo ezitshisiweyo, iimveliso ezineembobo, iindawo ezigqunyiweyo, iindawo ezigobileyo, iindawo zokusika

Ukusika i-plasma kusetyenziswa kakhulu kwimisebenzi yesinyithi, ukwenziwa koomatshini, i-aerospace, kunye neminye imimandla. Kwimisebenzi yesinyithi, ukusika i-plasma kungasetyenziselwa ukusika iindawo ezahlukeneyo zesinyithi, ezifana neepleyiti zesinyithi kunye nee-alloys ze-aluminium, ukuqinisekisa ukuchaneka kunye nomgangatho. Kwi-aerospace, ukusika i-plasma kusetyenziswa ukusika iindawo zeenqwelo-moya, ezifana nezixhobo zenjini kunye nezakhiwo ze-fuselage, ukuqinisekisa ukuchaneka kunye nokukhanya.

Ngamafutshane, njengeteknoloji yokusika esebenza kakuhle nechanekileyo, ukusika i-plasma kunamathuba amaninzi okusetyenziswa kunye nemfuno yemarike, kwaye kuya kudlala indima ebalulekileyo kwishishini lokuvelisa elizayo.

Iingenelo zeLaser Cutting Sheet Metal kwiMveliso

Kwimveliso, ukuchaneka nokusebenza kakuhle zezona zinto zibalulekileyo ekuveliseni iimveliso ezikumgangatho ophezulu. Ukusikwa kwesinyithi nge-laser kwazalelwa ukujongana nezi mfuno, okuzisa iingenelo ezibanzi kumashishini amaninzi. Ukusuka kwiimoto ukuya kwi-aerospace, ukusuka kwi-elektroniki ukuya kulwakhiwo, iteknoloji yokusika nge-laser itshintshe indlela ecutshungulwa kwaye isetyenziswa ngayo isinyithi.

Ukusikwa kwesinyithi nge-laser kufuna ukusetyenziswa kwe-laser enamandla aphezulu ukusika izinto ngokuchanekileyo okukhulu. Le nkqubo ivumela ukusikwa koyilo oluntsonkothileyo kunye neemilo ngelixa kunciphisa inkunkuma yezinto. Ukusikwa kwe-laser kunokusikwa kweentsimbi ezahlukeneyo, kubandakanya intsimbi, i-aluminium, kunye nobhedu, okwenza kube sisisombululo esinokusetyenziswa kwiimfuno ezininzi zokuvelisa.

Enye yezona nzuzo ziphambili zokusika i-laser sheet metal kukuchaneka kwayo okuphezulu. Ukuchaneka kwe-laser kwenza kube lula ukunyamezelana neenkcukacha ezintsonkothileyo, nto leyo ebangela ukuhlanganiswa okungenamthungo kweenxalenye kunye neendibano. Oku kuchaneka kubalulekile kumashishini apho nokuba kuthe tye okuncinci kunokukhokelela kwiingxaki ezibalulekileyo kwimveliso yokugqibela.

Ngaphezu koko, ukusika nge-laser kunika indlela ekhawulezayo nesebenzayo yokucubungula isinyithi sephepha kuneendlela zemveli. Ngenxa yetekhnoloji ye-CNC, uyilo lunokucwangciswa kwaye lusetyenziswe ngexesha elincinci lokuseta, ukunciphisa ixesha lokuguqula izinto kunye nokwandisa imveliso. Oku kuluncedo ngakumbi kumashishini afuna imveliso ephezulu.

Ukongeza ekuchanekeni kwayo nokusebenza kwayo kakuhle, isinyithi sokusika nge-laser sikwabonelela ngokonga iindleko zexesha elide. Ukunciphisa inkunkuma yezinto kunye nokukwazi ukuvelisa uyilo oluntsonkothileyo ngaphandle kwesidingo sokongeza izixhobo kunciphisa iindleko zemveliso kubavelisi, nto leyo ekhokelela ekongeni iyonke.

Ngaphezu koko, ukuguquguquka kwetekhnoloji yokusika nge-laser kwenza kube lula ukwenza ngokwezifiso kunye nokwenza iiprototype ngaphandle kwemida yeendlela zemveli zokusebenzisa izixhobo. Oku kuthetha ukuba abavelisi banokukhawuleza bazivumelanise notshintsho loyilo kwaye bavelise iibhetshi ezincinci zezinto ezenziwe ngokwezifiso ngaphandle kokufumana iindleko eziphezulu zokuseta.

Ngamafutshane, iingenelo zokusika isinyithi nge-laser kwishishini lokuvelisa azinakuphikiswa. Ukususela ekuchanekeni nasekusebenzeni kakuhle ukuya ekongeni iindleko kunye nokuguquguquka, iteknoloji yokusika nge-laser ibe sisixhobo esibalulekileyo kumashishini afuna iindawo zesinyithi ezikumgangatho ophezulu, ezenziwe ngokwezifiso. Njengoko iteknoloji iqhubeka ihambela phambili, amandla okusika nge-laser kwishishini lokuvelisa aya kuqhubeka ekhula, ebonelela ngezisombululo ezintsha ngakumbi kwishishini.

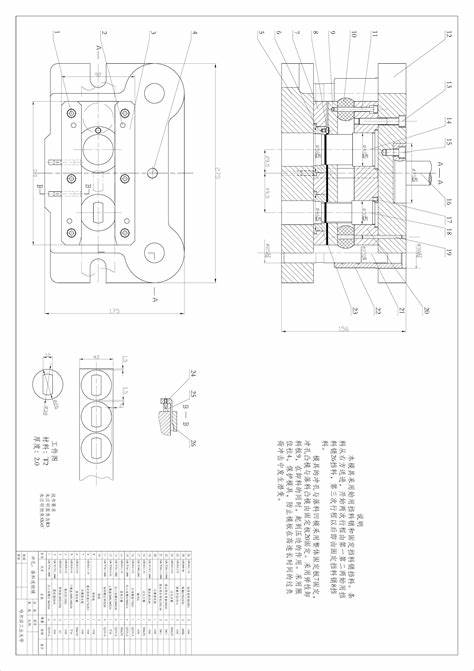

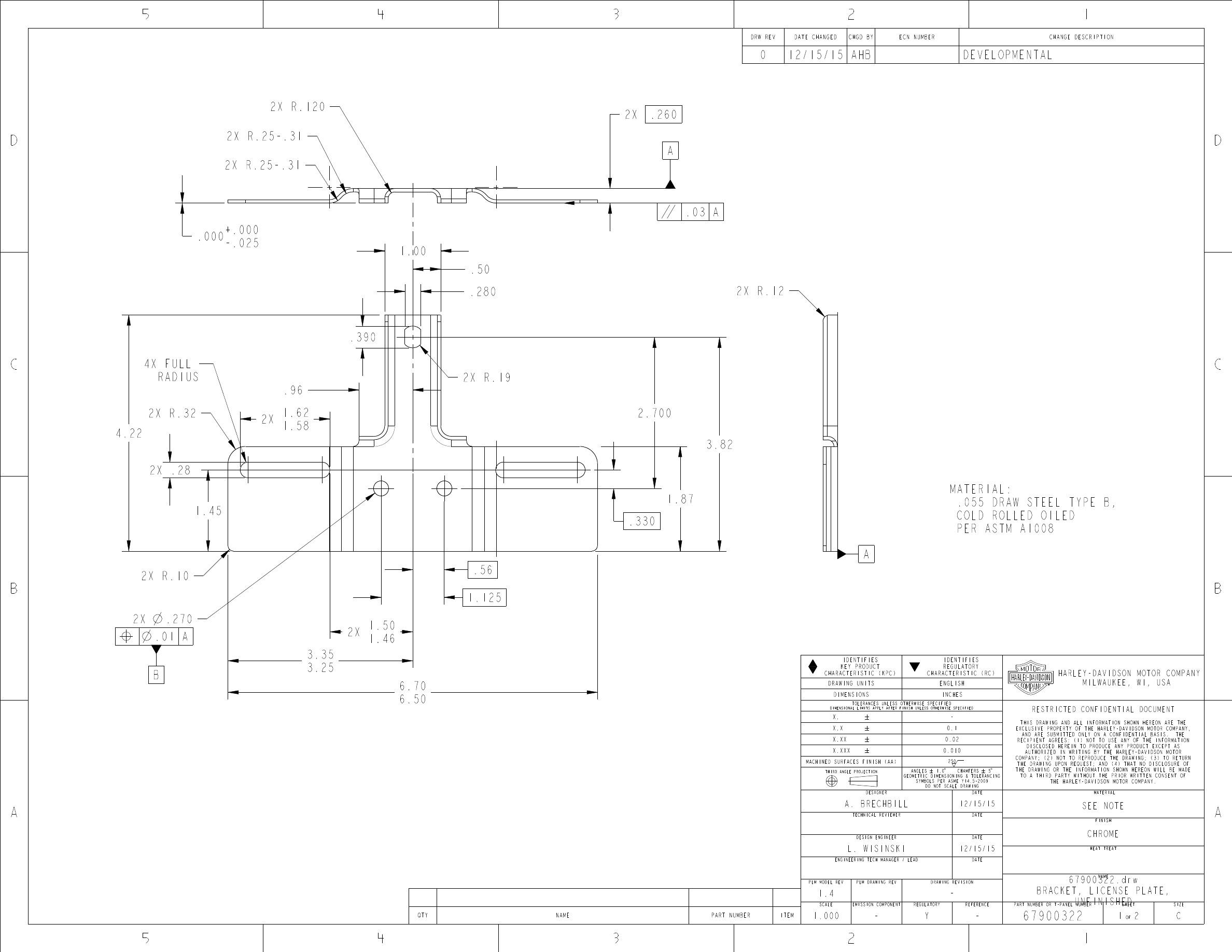

| Iinxalenye Zokwenziwa Kwesinyithi Esichanekileyo Ngokwesiko | ||||

| Isicatshulwa | Ngokwendlela odwebe ngayo (ubungakanani, izinto, ubukhulu, umxholo wokucubungula, kunye netekhnoloji efunekayo, njl.njl.) | |||

| Izinto eziphathekayo | Intsimbi yekhabhoni, intsimbi engatyiwayo, i-SPCc, i-SGCc, umbhobho, i-galvanized | |||

| Ukucutshungulwa | Ukusika nge-laser, ukugoba, ukuqhobosha, ukubhola, ukuwelda, ukwenza isinyithi, ukuhlanganisa, njl. | |||

| Unyango Lomphezulu | Ukubrasha, ukupolisha, ukufunxa, ukugquma ngepowder, ukuplata, | |||

| Ukunyamezelana | '+/-0.2mm, uhlolo lomgangatho we-QC oluyi-100% ngaphambi kokuba uhanjiswe, lunokubonelela ngefomu lokuhlolwa komgangatho | |||

| Ilogo | Ushicilelo lwesilika, uphawu lwelaser | |||

| Ubungakanani/Umbala | Yamkela ubungakanani/imibala eyenziwe ngokwezifiso | |||

| Ifomathi yoMzobo | .DWG/.DXF/.STEP/.IGS/.3DS/.STL/.SKP/.AI/.PDF/.JPG/.Draft | |||

| Isampuli yeXesha lokuFunda | Thetha ngexesha lokuhanjiswa ngokweemfuno zakho | |||

| Ukupakisha | Ngebhokisi/ibhokisi okanye ngokweemfuno zakho | |||

| Isatifikethi | I-ISO9001:SGS/TUV/ROHS | |||

Umzekelo

| Iinxalenye ezenziwe ngomatshini ezenziwe ngokwezifiso | |

| 1. Ubungakanani | Yenzelwe wena |

| 2. Umgangatho: | Eyenzelwe wena okanye i-GB |

| 3. Izinto eziphathekayo | Yenzelwe wena |

| 4. Indawo yefektri yethu | eTianjin, eTshayina |

| 5. Ukusetyenziswa: | Ukuhlangabezana neemfuno zabathengi |

| 6. Ukwaleka: | Yenzelwe wena |

| 7. Indlela yokusebenza: | Yenzelwe wena |

| 8. Uhlobo: | Yenzelwe wena |

| 9. Imilo yeCandelo: | Yenzelwe wena |

| 10. Uhlolo: | Ukuhlolwa okanye ukuhlolwa komthengi ngumntu wesithathu. |

| 11. Ukuhanjiswa: | Isitya, Isitya Esininzi. |

| 12. Malunga noMgangatho wethu: | 1) Akukho monakalo, akukho kugoba 2) Ubukhulu obuchanekileyo 3) Zonke iimpahla zingajongwa ngokuhlolwa ngumntu wesithathu ngaphambi kokuba zithunyelwe |

Umboniso weMveliso ogqityiweyo

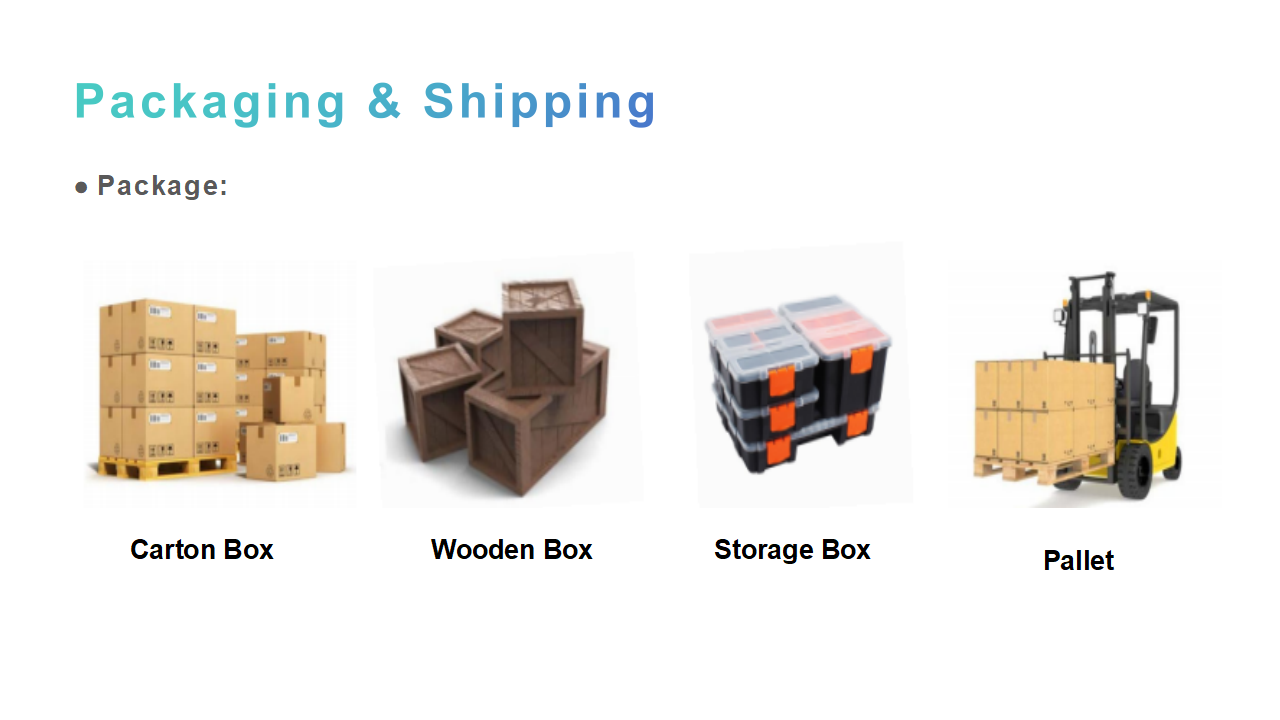

Ukupakishwa kunye nokuthunyelwa

Ukupakishwa kunye nokuthuthwa kweendawo ezisikiweyo ngeplasma kubalulekile ukuqinisekisa umgangatho wemveliso kunye nokuhanjiswa okukhuselekileyo. Okokuqala, ngenxa yokuchaneka okuphezulu kunye nomgangatho weendawo ezisikiweyo ngeplasma, izixhobo zokupakisha ezifanelekileyo kunye neendlela zibalulekile ukuthintela umonakalo ngexesha lokuthuthwa. Iindawo ezincinci ezisikiweyo ngeplasma zinokupakishwa kwiibhokisi zefoam okanye kwiibhokisi. Iindawo ezinkulu ezisikiweyo ngeplasma zihlala zipakishwa kwiikreyithi zomthi ukuze zikhuseleke ekonakaleni ngexesha lokuthuthwa.

Ngexesha lenkqubo yokupakisha, iindawo kufuneka ziqiniswe kakuhle kwaye zigqunywe ngokweempawu zazo ukuthintela umonakalo kwimpembelelo kunye nokungcangcazela ngexesha lokuthuthwa. Kwiindawo ezisikiweyo ngeplasma ezineemilo ezingaqhelekanga, izisombululo zokupakisha ezenzelwe wena ziyafuneka ukuqinisekisa uzinzo lwazo ngexesha lokuthuthwa.

Ngexesha lokuthuthwa, kubalulekile ukukhetha iqabane elithembekileyo lezothutho ukuqinisekisa ukuhanjiswa ngokukhuselekileyo nangexesha elifanelekileyo kwezixhobo ezisikiweyo ngeplasma. Kwizinto ezithunyelwa kwamanye amazwe, kubalulekile ukuqonda imigaqo efanelekileyo yokungenisa impahla kunye nemigangatho yokuthutha yelizwe ekuyiwa kulo ukuqinisekisa ukuhanjiswa kwempahla ngendlela ethe tye kunye nokuhanjiswa kwayo.

Ngaphezu koko, kwiindawo ezisikiweyo ngeplasma ezenziwe ngezinto ezikhethekileyo okanye ezineemilo ezintsonkothileyo, iimfuno ezikhethekileyo ezifana nokufuma kunye nokukhuselwa kokugqwala kufuneka ziqwalaselwe ngexesha lokupakisha kunye nokuthuthwa ukuqinisekisa ukuba umgangatho wemveliso awuchaphazeleki.

Ngamafutshane, ukupakishwa kunye nokuthuthwa kwezinto ezisikiweyo ngeplasma zizinto ezibalulekileyo ukuqinisekisa umgangatho wemveliso kunye nokwaneliseka kwabathengi. Ucwangciso olufanelekileyo kunye nokusebenza kuyafuneka ngokubhekiselele ekukhetheni izinto zokupakisha, ukuzaliswa okusisigxina, kunye nokukhetha indlela yokuthutha ukuqinisekisa ukuba iimveliso zisiwa kubathengi ngokukhuselekileyo nangokupheleleyo.

AMANDLA ENKAMPANI

Yenziwe eTshayina, inkonzo yodidi oluphezulu, umgangatho ophezulu, idume kwihlabathi liphela

1. Isiphumo sesikali: Inkampani yethu inekhonkco elikhulu lokubonelela ngempahla kunye nomzi-mveliso omkhulu wentsimbi, ifikelela kwiziphumo zesikali kwezothutho kunye nokuthengwa kwempahla, kwaye iba yinkampani yentsimbi edibanisa imveliso kunye neenkonzo.

2. Ukwahluka kwemveliso: Ukwahluka kwemveliso, nayiphi na intsimbi oyifunayo ingathengwa kuthi, ikakhulu ibandakanya izakhiwo zentsimbi, iireyile zentsimbi, iipali zeshiti zentsimbi, izibiyeli ze-photovoltaic, intsimbi yetshaneli, iikhoyili zesinyithi zesilicon kunye nezinye iimveliso, nto leyo eyenza ukuba iguquguquke ngakumbi Khetha uhlobo lwemveliso oyifunayo ukuhlangabezana neemfuno ezahlukeneyo.

3. Ubonelelo oluzinzileyo: Ukuba nomgca wemveliso ozinzileyo kunye nochungechunge lobonelelo kunokubonelela ngobonelelo oluthembekileyo ngakumbi. Oku kubaluleke kakhulu kubathengi abafuna intsimbi eninzi.

4. Impembelelo yophawu: Banempembelelo ephezulu yophawu kunye nemarike enkulu

5. Inkonzo: Inkampani enkulu yentsimbi edibanisa ukwenziwa ngokwezifiso, uthutho kunye nemveliso

6. Ukhuphiswano lwamaxabiso: ixabiso elifanelekileyo

UKUTYELELA KWABATHENGI

FAQ

1. Ndingayifumana njani ikowuteshini kuwe?

Ungasishiyela umyalezo, kwaye siza kuphendula yonke imiyalezo ngexesha elifanelekileyo.

2. Ngaba uza kuzihambisa iimpahla ngexesha elifanelekileyo?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni ophezulu kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3. Ndingafumana iisampulu ngaphambi kokuba ndi-odole?

Ewe, ewe. Ngokwesiqhelo iisampulu zethu zisimahla, singazivelisa ngeesampulu zakho okanye ngemizobo yobugcisa.

4. Ithini imiqathango yakho yokuhlawula?

Ixesha lethu lokuhlawula eliqhelekileyo yidiphozithi ye-30%, kwaye intsalela imele i-B/L.

5. Ngaba uyayamkela into yokuhlolwa ngumntu wesithathu?

Ewe siyamkela ngokupheleleyo.

6. Siyithemba njani inkampani yakho?

Siziingcali kwishishini lentsimbi kangangeminyaka emininzi njengomthengisi wegolide, ikomkhulu likwiphondo laseTianjin, samkelekile ukuphanda ngazo zonke iindlela, nangayiphi na indlela.