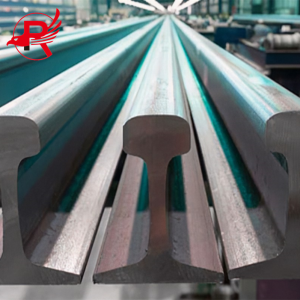

Iziqwenga zentsimbi zombane ze-GB eziQokelelweyo eziBandayo ezisekelwe kwiSilicon Steel Crgo zeMagnetic Transformer Ei Iron Core

Iinkcukacha zeMveliso

Ngokweenkalo ezahlukeneyo zokusetyenziswa kunye netekhnoloji yokucubungula, ikhoyili yentsimbi yesilicon inokwahlulwa ibe yikhoyili yentsimbi yesilicon engajoliswanga, ikhoyili yentsimbi yesilicon ejongiweyo kunye nekhoyili yentsimbi yesilicon enemilinganiselo emithathu. Ukusetyenziswa kwezi ntlobo zintathu zeekhoyili zentsimbi yesilicon kushishino lwamandla nako kwahlukile.

Iikhoyili zesinyithi zesilicon ezingajoliswanga zisetyenziswa kakhulu kwizixhobo zombane ezifana neentambo kunye neemoto ezisebenzisa i-frequency ephakathi nephezulu, kwaye iikhoyili zesinyithi zesilicon ezijoliswanga zisetyenziswa kakhulu kwizixhobo ezinkulu zokuguqula amandla ezisebenza kakuhle, ezifana nee-turbines kunye neejenereyitha. Iikhoyili zesinyithi zesilicon ezinemilinganiselo emithathu zisetyenziswa kwizixhobo zombane ezifana nee-power transformers kunye nee-high-frequency transformers.

Iimbonakalo

I-coil yesinyithi ye-silicon yenziwe nge-ferrosilicon kunye nezinye izinto ezidibanisayo. I-Ferrosilicon yeyona nto iphambili. Kwangaxeshanye, kongezwa inani elincinci le-carbon, i-silicon, i-manganese, i-aluminium kunye nezinye izinto ukuphucula amandla, ukuhanjiswa kwamandla kunye nokumelana nokugqwala kwezinto.

| Uphawu lwentengiso | Ubukhulu obuqhelekileyo (mm) | 密度(kg/dm³) | Uxinano(kg/dm³)) | Ubuncinci bokufakelwa kwemagnethi i-B50(T) | I-coefficient encinci yokubeka i-stacking (%) |

| B35AH230 | 0.35 | 7.65 | 2.30 | 1.66 | 95.0 |

| B35AH250 | 7.65 | 2.50 | 1.67 | 95.0 | |

| B35AH300 | 7.70 | 3.00 | 1.69 | 95.0 | |

| B50AH300 | 0.50 | 7.65 | 3.00 | 1.67 | 96.0 |

| B50AH350 | 7.70 | 3.50 | 1.70 | 96.0 | |

| B50AH470 | 7.75 | 4.70 | 1.72 | 96.0 | |

| B50AH600 | 7.75 | 6.00 | 1.72 | 96.0 | |

| B50AH800 | 7.80 | 8.00 | 1.74 | 96.0 | |

| B50AH1000 | 7.85 | 10.00 | 1.75 | 96.0 | |

| B35AR300 | 0.35 | 7.80 | 2.30 | 1.66 | 95.0 |

| B50AR300 | 0.50 | 7.75 | 2.50 | 1.67 | 95.0 |

| B50AR350 | 7.80 | 3.00 | 1.69 | 95.0 |

Isicelo

Ngenxa yokwakheka okukhethekileyo kunye netekhnoloji yokucubungula i-silicon steel coil, ineempawu ezininzi ezikhethekileyo:

1. Ukungena okuphezulu: Ukumelana kwekhoyili yentsimbi yesilicon kuphantsi kakhulu, ngoko ke umsinga ungadlula lula kwizinto, nto leyo ebangela amandla amakhulu emagnethi.

2. Ukulahleka kwesinyithi okuphantsi: Emva kokufakelwa kwe-silicon steel coil, nokuba emva kokufakelwa kwe-magnetization emininzi kunye ne-demagnetization, ukulahleka kwamandla kuncinci kakhulu, enye yezona nzuzo zinkulu ze-silicon steel coil.

3. Amandla okungenisa amandla emagnethi aphantsi: iipropati zemagnethi ze-silicon steel coil zilungile kakhulu, kwaye amandla okungenisa amandla emagnethi aphakamileyo anokufezekiswa, oko kuthetha ukuba ukusetyenziswa kwamandla kuncinci kakhulu kwaye ubomi bude kakhulu.

4. Ubunzima obulula, ingxolo ephantsi, ukusebenza kakuhle okuphezulu: ikhoyili yesinyithi yesilicon ubunzima obulula, ingxolo ephantsi, ngoko ke ekwenzeni izixhobo zamandla, ikhoyili yesinyithi yesilicon isetyenziswa kakhulu ukugcina ukusebenza kakuhle kunye nozinzo lwezixhobo.

Ukupakishwa kunye nokuthunyelwa

1. Ngexesha lenkqubo yokupakisha, iikona ezibukhali okanye imiphetho ebukhali kufuneka kuthintelwe kwiindawo ezinxibelelanayo zemveliso kunye nezixhobo zokupakisha ukuze kuthintelwe ukukrwela okanye ukonakalisa imveliso.

2. Xa kukhethwa indlela yokuthutha, indlela yokuthutha efanelekileyo kufuneka ikhethwe ngokwezinto ezinje ngobungakanani bemveliso, ubunzima kunye nomgama wokuthutha.

3. Kwinkqubo yokuthutha, kufuneka kuqiniswe ukubekwa esweni nokukhuselwa kweemveliso zesinyithi sesilicon ukuqinisekisa ukuba iimveliso zinokuthunyelwa ngokukhuselekileyo kwindawo eziya kuyo, kunye nokujongana neengxaki ezinokubakho ekuthuthweni ngexesha elifanelekileyo.

Ngokubanzi, inkqubo yokupakisha iimveliso zesinyithi sesilicon kufuneka ilandele imigangatho kunye neemfuno zesizwe ezifanelekileyo ukuqinisekisa ukukhethwa kunye nokuphathwa ngokufanelekileyo kwezinto zokupakisha kunye nezinye iinkcukacha, ukuqinisekisa ukhuseleko kunye nokuthembeka kwemveliso kuyo yonke inkqubo yokuthutha izinto.

FAQ

Umbuzo 1. Iphi ifektri yakho?

A1: Iziko lokucubungula lenkampani yethu likwiTianjin, eTshayina. Elixhotyiswe kakuhle ziintlobo ngeentlobo zoomatshini, njengomatshini wokusika nge-laser, umatshini wokupolisha isipili njalo njalo. Singabonelela ngeenkonzo ezahlukeneyo ezenzelwe wena ngokweemfuno zabathengi.

Umbuzo 2. Zeziphi iimveliso eziphambili zenkampani yakho?

A2: Iimveliso zethu eziphambili zipleyiti/iphepha lesinyithi esingenasici, ikhoyili, umbhobho ojikelezileyo/osikwere, ibha, itshaneli, inqwaba yephepha lesinyithi, i-strut yesinyithi, njl.njl.

Umbuzo 3. Uwulawula njani umgangatho?

A3: Isiqinisekiso sovavanyo lweMill sinikezelwa kunye nokuthunyelwa, Uhlolo lweQela lesithathu luyafumaneka.

Umbuzo 4. Zithini iingenelo zenkampani yakho?

A4: Sinabasebenzi abaninzi abaziingcali, abasebenzi bezobugcisa, amaxabiso angcono kwaye

inkonzo engcono kakhulu emva kokwenza ii-dales kunezinye iinkampani zentsimbi engagqwaliyo.

Umbuzo 5. Zingaphi iidolophu osele uzithumele kwamanye amazwe?

A5: Ithunyelwa kumazwe angaphezu kwama-50 ikakhulu evela eMelika, eRashiya, e-UK, eKuwait,

IYiputa, iTurkey, iJordan, iIndiya, njl.

Umbuzo 6. Ngaba ungasinika isampuli?

A6: Iisampuli ezincinci zisevenkileni kwaye zingabonelela ngeesampuli simahla. Iisampuli ezenziwe ngokwezifiso ziya kuthatha malunga neentsuku ezi-5-7.