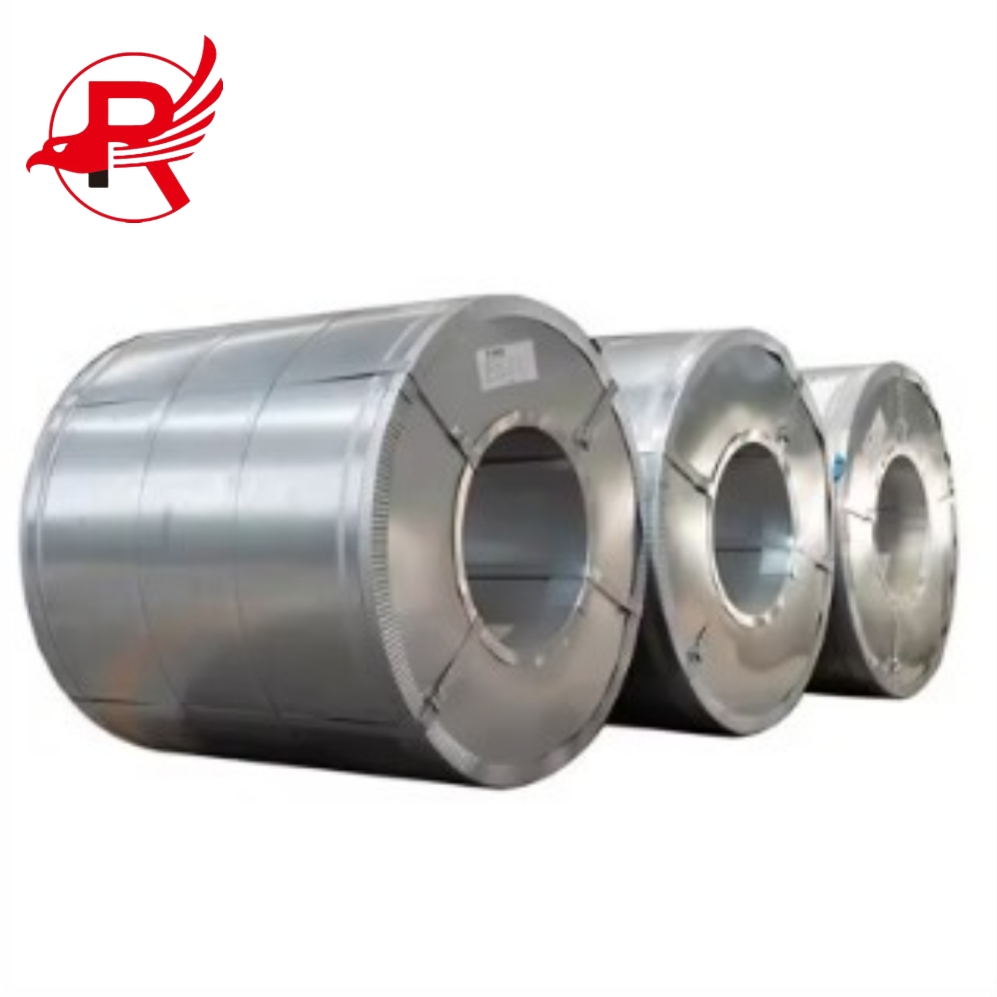

I-GB Standard Silicon Lamination Steel Coil/Strip/Sheet, Relay Steel kunye neTransformer Steel

Iinkcukacha zeMveliso

I-silicon steel coil, njengenye yezinto eziphambili kushishino lwanamhlanje, isetyenziswa kakhulu kwicandelo leenkqubo zamandla kunye neemoto, idlala indima ebalulekileyo. Eyona nto isetyenziswa kakhulu kukwenza iitransformers, iijenereyitha, iimoto kunye nezinye iintlobo zezinto eziphambili zezixhobo zombane ezisebenzayo, ukuphucula ngokufanelekileyo ukusebenza kwe-electromagnetic yezixhobo kunye nokusebenza kakuhle kokuguqulwa kwamandla.

Iimbonakalo

Intsimbi ye-silicon alloy enomxholo we-silicon oyi-1.0 ~ 4.5% kunye nomxholo wekhabhoni ongaphantsi kwe-0.08% ibizwa ngokuba yi-silicon steel. Ineempawu zokungena okuphezulu, ukunyanzeliswa okuphantsi kunye nokumelana okukhulu, ngoko ke ukulahleka kwe-hysteresis kunye nokulahleka komsinga we-eddy kuncinci. Isetyenziswa kakhulu njengezinto zemagnethi kwiimoto, ii-transformers, izixhobo zombane kunye nezixhobo zombane. Ukuze kuhlangatyezwane neemfuno zokucubungula ukubhoboza kunye nokucheba xa kusenziwa izixhobo zombane, kufuneka kwakhona ukuba ne-plasticity ethile. Ukuze kuphuculwe ukuthambekela kwemagnethi kunye nokunciphisa ukulahleka kwe-hysteresis, umxholo wokungcola onobungozi kufuneka ube phantsi kangangoko, kwaye imo yeplate kufuneka ibe tyaba kwaye umgangatho womphezulu ulungile.

| Uphawu lwentengiso | Ubukhulu obuqhelekileyo (mm) | 密度(kg/dm³) | Uxinano(kg/dm³)) | Ubuncinci bokufakelwa kwemagnethi i-B50(T) | I-coefficient encinci yokubeka i-stacking (%) |

| B35AH230 | 0.35 | 7.65 | 2.30 | 1.66 | 95.0 |

| B35AH250 | 7.65 | 2.50 | 1.67 | 95.0 | |

| B35AH300 | 7.70 | 3.00 | 1.69 | 95.0 | |

| B50AH300 | 0.50 | 7.65 | 3.00 | 1.67 | 96.0 |

| B50AH350 | 7.70 | 3.50 | 1.70 | 96.0 | |

| B50AH470 | 7.75 | 4.70 | 1.72 | 96.0 | |

| B50AH600 | 7.75 | 6.00 | 1.72 | 96.0 | |

| B50AH800 | 7.80 | 8.00 | 1.74 | 96.0 | |

| B50AH1000 | 7.85 | 10.00 | 1.75 | 96.0 | |

| B35AR300 | 0.35 | 7.80 | 2.30 | 1.66 | 95.0 |

| B50AR300 | 0.50 | 7.75 | 2.50 | 1.67 | 95.0 |

| B50AR350 | 7.80 | 3.00 | 1.69 | 95.0 |

Isicelo

Intsimbi yesilicon ine-induction ephezulu yemagnethi, kwaye umsinga wokukhupha umoya wentsimbi uyancitshiswa, nto leyo ekwagcina amandla. I-induction ephezulu yemagnethi yentsimbi yesilicon inokwenza uyilo lwe-induction ephezulu yemagnethi (Bm) lube phezulu, ubungakanani bentsimbi buncinci, bubunzima obuphantsi, oko konga intsimbi yesilicon, iingcingo, izixhobo zokufaka ubushushu kunye nezixhobo zokwakha, zombini iindleko zokulahleka kwemoto kunye ne-transformer kunye nokuvelisa ziyancitshiswa, kodwa kulula ukuyihlanganisa nokuyithutha. Imoto, equlathe i-punch ejikelezayo enamazinyo eyenza intsimbi, isebenza kwimeko yokusebenza. Ipleyiti yentsimbi yesilicon kufuneka ibe yi-isotropic yemagnethi kwaye yenziwe ngentsimbi yesilicon engajoliswanga. Ii-transformers ezenziwe ngamaqhekeza afakwe kwintsimbi yesinyithi okanye amaqhekeza ajikelezileyo kwintsimbi yesinyithi asebenza ngexesha lokuphumla kwaye zenziwe ngentsimbi yesilicon ejikelezileyo ebandayo ene-anisotropy ephezulu yemagnethi. Ukongeza, intsimbi yesilicon kufuneka ibe nepropathi elungileyo yokubhoboza, umphezulu ogudileyo kunye nobukhulu obufanayo, ifilimu elungileyo yokugquma kunye nokuguga okuncinci kwemagnethi.

Ukupakishwa kunye nokuthunyelwa

1. Ngexesha lenkqubo yokupakisha, iikona ezibukhali okanye imiphetho ebukhali kufuneka kuthintelwe kwiindawo ezinxibelelanayo zemveliso kunye nezixhobo zokupakisha ukuze kuthintelwe ukukrwela okanye ukonakalisa imveliso.

2. Xa kukhethwa indlela yokuthutha, indlela yokuthutha efanelekileyo kufuneka ikhethwe ngokwezinto ezinje ngobungakanani bemveliso, ubunzima kunye nomgama wokuthutha.

3. Kwinkqubo yokuthutha, kufuneka kuqiniswe ukubekwa esweni nokukhuselwa kweemveliso zesinyithi sesilicon ukuqinisekisa ukuba iimveliso zinokuthunyelwa ngokukhuselekileyo kwindawo eziya kuyo, kunye nokujongana neengxaki ezinokubakho ekuthuthweni ngexesha elifanelekileyo.

Ngokubanzi, inkqubo yokupakisha iimveliso zesinyithi sesilicon kufuneka ilandele imigangatho kunye neemfuno zesizwe ezifanelekileyo ukuqinisekisa ukukhethwa kunye nokuphathwa ngokufanelekileyo kwezinto zokupakisha kunye nezinye iinkcukacha, ukuqinisekisa ukhuseleko kunye nokuthembeka kwemveliso kuyo yonke inkqubo yokuthutha izinto.

FAQ

Umbuzo 1. Iphi ifektri yakho?

A1: Iziko lokucubungula lenkampani yethu likwiTianjin, eTshayina. Elixhotyiswe kakuhle ziintlobo ngeentlobo zoomatshini, njengomatshini wokusika nge-laser, umatshini wokupolisha isipili njalo njalo. Singabonelela ngeenkonzo ezahlukeneyo ezenzelwe wena ngokweemfuno zabathengi.

Umbuzo 2. Zeziphi iimveliso eziphambili zenkampani yakho?

A2: Iimveliso zethu eziphambili zipleyiti/iphepha lesinyithi esingenasici, ikhoyili, umbhobho ojikelezileyo/osikwere, ibha, itshaneli, inqwaba yephepha lesinyithi, i-strut yesinyithi, njl.njl.

Umbuzo 3. Uwulawula njani umgangatho?

A3: Isiqinisekiso sovavanyo lweMill sinikezelwa kunye nokuthunyelwa, Uhlolo lweQela lesithathu luyafumaneka.

Umbuzo 4. Zithini iingenelo zenkampani yakho?

A4: Sinabasebenzi abaninzi abaziingcali, abasebenzi bezobugcisa, amaxabiso angcono kwaye

inkonzo engcono kakhulu emva kokwenza ii-dales kunezinye iinkampani zentsimbi engagqwaliyo.

Umbuzo 5. Zingaphi iidolophu osele uzithumele kwamanye amazwe?

A5: Ithunyelwa kumazwe angaphezu kwama-50 ikakhulu evela eMelika, eRashiya, e-UK, eKuwait,

IYiputa, iTurkey, iJordan, iIndiya, njl.

Umbuzo 6. Ngaba ungasinika isampuli?

A6: Iisampuli ezincinci zisevenkileni kwaye zingabonelela ngeesampuli simahla. Iisampuli ezenziwe ngokwezifiso ziya kuthatha malunga neentsuku ezi-5-7.