I-ASTM Equal Angle Steel Carbon Steel Mild Steel Corner Angle Bar

Iinkcukacha zeMveliso

I-engile yentsimbi yekhabhoniIibhari luhlobo oluqhelekileyo lwentsimbi yokwakha esetyenziselwa ukwakhiwa kunye nokwenziwa kwezinto ezahlukeneyo. Ngokwesiqhelo zenziwe ngentsimbi yekhabhoni, enika amandla kunye nokwakheka okuhle. Nazi ezinye iinkcukacha ngokubanzi malunga neebhari ze-angle zentsimbi yekhabhoni:

Izinto eziphathekayo: Iibhari ze-angle zentsimbi yekhabhoni zihlala zenziwe ngentsimbi enekhabhoni ephantsi, equlethe inani elincinci lekhabhoni, ngokuqhelekileyo iphakathi kwe-0.05% ukuya kwi-0.25%. Oku kuzenza zilungele ukuwelda, ukwenza, kunye nokulungisa.

Imilo: Iibha ze-angle zentsimbi yekhabhoni zine-cross-section emile okwe-L. Zenziwa ngokugoba iqhekeza elinye lentsimbi kwi-engile ye-90-degree, nto leyo ebangela imilenze emibini enobude obulinganayo okanye obungalinganiyo.

Ubukhulu: Iibha ze-angle zentsimbi yekhabhoni ziyafumaneka kwiindidi ezahlukeneyo zobukhulu obuqhelekileyo, kubandakanya ubude bemilenze, ubukhulu, kunye nobubanzi (obulinganiswa ukusuka kumda ongaphandle womlenze omnye ukuya kumda ongaphandle womnye).

Ukugqitywa komphezulu: Zingabonelelwa ngomphetho womatshini wokugaya, onokuba neziphene ezithile kumphezulu, okanye ngomphetho ogudileyo nocolekileyo.

Izicelo: Iibhari ze-angle zentsimbi yekhabhoni zisetyenziswa kakhulu kwizicelo zesakhiwo nezokwakha, kubandakanya izakhelo zesakhiwo, izixhobo zokuxhasa, izixhaso, kunye nokuqinisa. Zikwasetyenziswa nakwizicelo zemizi-mveliso kunye noomatshini.

Imigangatho: Iibha ze-angle zentsimbi yekhabhoni zenziwe ukuhlangabezana nemigangatho eyahlukeneyo yamazwe ngamazwe, efana ne-ASTM, JIS, EN, kunye ne-GB/T.

| Umgangatho | I-AISI, i-ASTM, i-DIN, i-GB, i-JIS, i-SUS | |||

| Ububanzi | 2mm ukuya kwi-400 mm okanye 1/8" ukuya kwi-15" okanye ngokweemfuno zomthengi | |||

| Ubude | Iimitha ezi-1 ukuya kwezi-6 okanye ngokweemfuno zomthengi | |||

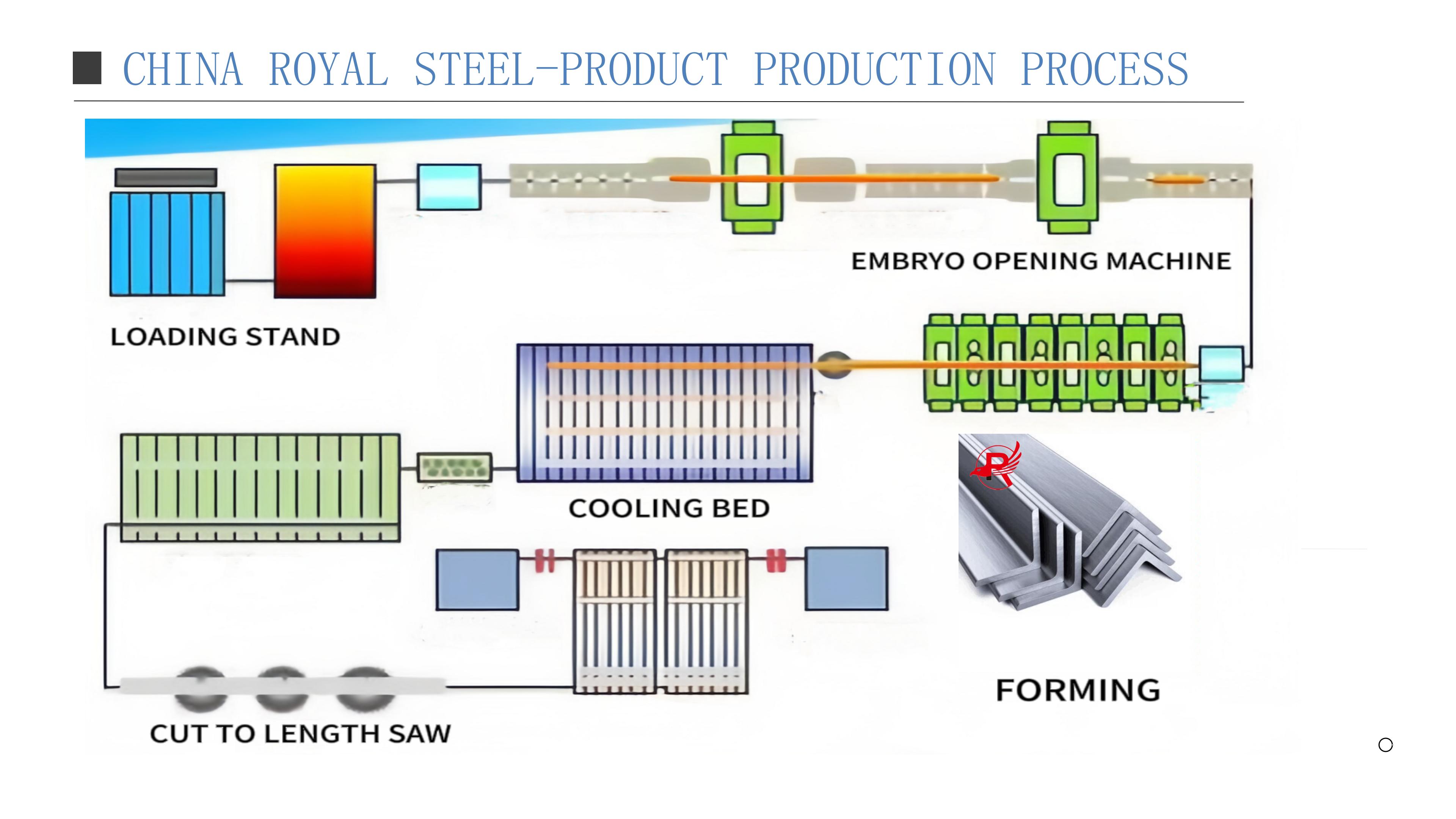

| Unyango/Indlela | Iqengqeleka ngobushushu, itsalwa kubanda, i-Annealed, i-Grinding | |||

| Umphezulu | I-Satin, 400#, 600~1000# isipilix, i-HL brushed, iBrushed Mirror (iintlobo ezimbini zokugqiba umbhobho omnye) | |||

| Izicelo | I-oyile, izixhobo ze-elektroniki, iikhemikhali, amayeza, impahla, ukutya, oomatshini, ulwakhiwo, amandla enyukliya, inqwelo-moya, ezomkhosi kunye amanye amashishini | |||

| Imigaqo yoRhwebo | I-EXW, i-FOB, i-CFR, i-CIF | |||

| Ixesha lokuzisa | Ithunyelwa kwiintsuku ezisi-7-15 emva kwentlawulo | |||

| Iphakheji | Iphakheji eqhelekileyo efanelekileyo elwandle okanye njengoko kufuneka | |||

| UKUPAKISHA OKUFANELEKILEYO KOLWANDLE | I-GP engama-20ft: 5.8m (ubude) x 2.13m (ububanzi) x 2.18m (ukuphakama) malunga ne-24-26CBM | |||

| I-GP engama-40ft: 11.8m (ubude) x 2.13m (ububanzi) x 2.18m (ukuphakama) malunga ne-54CBM 40ft HG: 11.8m (ubude) x 2.13m (ububanzi) x 2.72m (ukuphakama) malunga ne-68CBM | ||||

| Intsimbi elinganayo ye-engile | |||||||

| Ubungakanani | Ubunzima | Ubungakanani | Ubunzima | Ubungakanani | Ubunzima | Ubungakanani | Ubunzima |

| (MM) | (KG/M) | (MM) | (KG/M) | (MM) | (KG/M) | (MM) | (KG/M) |

| 20*3 | 0.889 | 56*3 | 2.648 | 80*7 | 8.525 | 12*10 | 19.133 |

| 20*4 | 1.145 | 56*4 | 3.489 | 80*8 | 9.658 | 125*12 | 22.696 |

| 25*3 | 1.124 | 56*5 | 4.337 | 80*10 | 11.874 | 12*14 | 26.193 |

| 25*4 | 1.459 | 56*6 | 5.168 | 90*6 | 8.35 | 140*10 | 21.488 |

| 30*3 | 1.373 | 63*4 | 3.907 | 90*7 | 9.656 | 140*12 | 25.522 |

| 30*4 | 1.786 | 63*5 | 4.822 | 90*8 | 10.946 | 140*14 | 29.49 |

| 36*3 | 1.656 | 63*6 | 5.721 | 90*10 | 13.476 | 140*16 | 33.393 |

| 36*4 | 2.163 | 63*8 | 7.469 | 90*12 | 15.94 | 160*10 | 24.729 |

| 36*5 | 2.654 | 63*10 | 9.151 | 100*6 | 9.366 | 160*12 | 29.391 |

| 40*2.5 | 2.306 | 70*4 | 4.372 | 100*7 | 10.83 | 160*14 | 33.987 |

| 40*3 | 1.852 | 70*5 | 5.697 | 100*8 | 12.276 | 160*16 | 38.518 |

| 40*4 | 2.422 | 70*6 | 6.406 | 100*10 | 15.12 | 180*12 | 33.159 |

| 40*5 | 2.976 | 70*7 | 7.398 | 100*12 | 17.898 | 180*14 | 38.383 |

| 45*3 | 2.088 | 70*8 | 8.373 | 100*14 | 20.611 | 180*16 | 43.542 |

| 45*4 | 2.736 | 75*5 | 5.818 | 100*16 | 23.257 | 180*18 | 48.634 |

| 45*5 | 3.369 | 75*6 | 6.905 | 110*7 | 11.928 | 200*14 | 42.894 |

| 45*6 | 3.985 | 75*7 | 7.976 | 110*8 | 13.532 | 200*16 | 48.68 |

| 50*3 | 2.332 | 75*8 | 9.03 | 110*10 | 16.69 | 200*18 | 54.401 |

| 50*4 | 3.059 | 75*10 | 11.089 | 110*12 | 19.782 | 200*20 | 60.056 |

| 50*5 | 3.77 | 80*5 | 6.211 | 110*14 | 22.809 | 200*24 | 71.168 |

| 50*6 | 4.456 | 80*6 | 7.376 | 125*8 | 15.504 | ||

Imilo: Ezi migca ye-engile zine-cross-section efana ne-L, enemilenze emibini enobude obulinganayo okanye obungalinganiyo edibana kwi-engile ye-90-degree. Le milo iyenza ifaneleke ukubonelela ngenkxaso yesakhiwo kunye nokuqiniswa kwizicelo ezahlukeneyo.

Amandla kunye nomthamo wokuthwala umthwalo: Iibha ze-carbon angle zenzelwe ukubonelela ngamandla aphezulu okutsalwa, okwenza zifaneleke ukuxhasa imithwalo enzima kunye nokubonelela ngozinzo lwesakhiwo kwizakhiwo.

Ukuguquguquka: Zifumaneka ngobukhulu obahlukeneyo nobukhulu obahlukeneyo, nto leyo evumela ukusetyenziswa ngeendlela ezahlukeneyo. Zingasetyenziselwa ukwakha iifreyimu, ukuxhasa, ukuxhasa, kunye nanjengezinto ezahlukeneyo kwizakhiwo ezahlukeneyo.

Ukumelana nokugqwala: Ngokuxhomekeke kwi-alloy ethile kunye nonyango lomphezulu, ii-carbon angle bars zinokubonelela ngamanqanaba ahlukeneyo okuxhathisa ukugqwala. Unyango olufanelekileyo lomphezulu okanye ukugquma kunokuphucula ukuqina kwazo kwiindawo ezigqwalisayo.

Ukukwazi ukusebenza kunye nokudityaniswa: Iibhari ze-carbon angle zinokucuthwa ngomatshini, zisikwe, kwaye zifakwe i-welded, nto leyo evumela ukuguquguquka kwiinkqubo zokwenza nokwakha.

Ukuthobela imigangatho: Ezi angle bars zihlala zenziwe ukuze zihlangabezane nemigangatho yoshishino neyehlabathi, efana ne-ASTM, i-AISI, i-DIN, i-EN, kunye ne-JIS, ukuqinisekisa ukuba ziyahlangabezana neemfuno ezithile zoomatshini kunye nobukhulu.

Iimbonakalo

Iibha ze-carbon angle, ezaziwa ngokuba ziibha ze-carbon steel angle, luhlobo lwenxalenye yentsimbi yesakhiwo esetyenziswa kakhulu ekwakheni, ekuveliseni, nakwimisebenzi yemizi-mveliso. Nazi ezinye zeempawu eziphambili zeebha ze-carbon angle:

Izinto eziphathekayo: Iibha ze-carbon angle zenziwe ngentsimbi yekhabhoni, eyi-iron-carbon alloy equlethe ipesenti encinci yekhabhoni (ngesiqhelo ingaphantsi kwe-2%). Le nto inika amandla amahle, ukuqina, kunye nokudityaniswa.

Imilo: Ezi migca ye-engile zine-cross-section efana ne-L, enemilenze emibini enobude obulinganayo okanye obungalinganiyo edibana kwi-engile ye-90-degree. Le milo iyenza ifaneleke ukubonelela ngenkxaso yesakhiwo kunye nokuqiniswa kwizicelo ezahlukeneyo.

Amandla kunye nomthamo wokuthwala umthwalo: Iibha ze-carbon angle zenzelwe ukubonelela ngamandla aphezulu okutsalwa, okwenza zifaneleke ukuxhasa imithwalo enzima kunye nokubonelela ngozinzo lwesakhiwo kwizakhiwo.

Ukuguquguquka: Zifumaneka ngobukhulu obahlukeneyo nobukhulu obahlukeneyo, nto leyo evumela ukusetyenziswa ngeendlela ezahlukeneyo. Zingasetyenziselwa ukwakha iifreyimu, ukuxhasa, ukuxhasa, kunye nanjengezinto ezahlukeneyo kwizakhiwo ezahlukeneyo.

Ukumelana nokugqwala: Ngokuxhomekeke kwi-alloy ethile kunye nonyango lomphezulu, ii-carbon angle bars zinokubonelela ngamanqanaba ahlukeneyo okuxhathisa ukugqwala. Unyango olufanelekileyo lomphezulu okanye ukugquma kunokuphucula ukuqina kwazo kwiindawo ezigqwalisayo.

Ukukwazi ukusebenza kunye nokudityaniswa: Iibhari ze-carbon angle zinokucuthwa ngomatshini, zisikwe, kwaye zifakwe i-welded, nto leyo evumela ukuguquguquka kwiinkqubo zokwenza nokwakha.

Ukuthobela imigangatho: Ezi angle bars zihlala zenziwe ukuze zihlangabezane nemigangatho yoshishino neyehlabathi, efana ne-ASTM, i-AISI, i-DIN, i-EN, kunye ne-JIS, ukuqinisekisa ukuba ziyahlangabezana neemfuno ezithile zoomatshini kunye nobukhulu.

Isicelo

Iibha ze-angle ze-Mild steel (MS), ezaziwa ngokuba yi-mild steel angle iron, zisetyenziswa kakhulu kwizicelo ezahlukeneyo ngenxa yokuguquguquka kwazo kunye neempawu zesakhiwo. Nazi ezinye zezicelo eziqhelekileyo zeebha ze-angle ze-MS:

Ulwakhiwo: Iibha ze-angle ze-MS zisetyenziswa kakhulu ekwakheni iifreyimu, ukuxhasa, kunye nezicelo zokuxhasa. Zihlala zisetyenziswa ukwenza iifreyimu zezakhiwo, iibhulorho, kunye neeprojekthi zeziseko.

Ukuvelisa: Ezi angle bars zisetyenziswa ekwenziweni kwezinto zokwakha oomatshini, izixhobo, kunye nezakhiwo zoshishino. Zibonelela ngenkxaso ebalulekileyo kunye nokuqinisa kwicandelo lemveliso.

Uyilo lwezakhiwo kunye nolwangaphakathi: Kwiiprojekthi zoyilo lwezakhiwo nezangaphakathi, ii-engile zentsimbi ezithambileyo zisetyenziselwa ukwenza izakhiwo zesakhelo, izixhasi zezinto ezifakelwayo, kunye nezinto zokuhombisa. Zingasetyenziselwa iinjongo zobuhle kunye nenkxaso yesakhiwo esebenzayo.

Iishelufu kunye neerakhi: Iibha ze-MS angle zisetyenziswa kakhulu ekwakhiweni kwee-shelf units, ii-storage racks, kunye nezakhiwo ze-warehouse ngenxa yamandla azo kunye nokukwazi kwazo ukuthwala umthwalo.

Ukwenziwa kwefenitshala: Kwishishini lefenitshala, ii-engile zentsimbi ezithambileyo zisetyenziselwa ukwakha iifreyimu, izakhiwo ezixhasayo, kunye nezibiyeli zeentlobo ngeentlobo zefenitshala, kubandakanya iitafile, izitulo, kunye neeyunithi zeeshelufu.

Ukwenziwa kwezithuthi nezixhobo: Ezi bha ze-engile zisetyenziswa ekwenziweni nasekuqiniseni iifreyimu zezithuthi, iitreyila, kunye nezixhobo ezixhasayo ngenxa yokuqina kwazo nokuqina kwazo.

Izicelo zezolimoKwicandelo lezolimo, ii-MS angle bars zisetyenziselwa ukwakha izakhiwo zefama, izixhobo ezixhasayo, kunye neendawo zokugcina izinto.

Iiprojekthi ze-DIY: Iibha ze-engile zentsimbi ezithambileyo zihlala zisetyenziswa kwiiprojekthi zokuzenzela (zokuzenzela), kubandakanya ukuhlaziywa kwekhaya, ukwakha izakhelo zezakhiwo ezenziwe ngokwezifiso, kunye nokudala izixhasi zezicelo ezahlukeneyo.

Ukupakishwa kunye nokuthunyelwa

Intsimbi ye-Anglengokubanzi ipakishwa ngokufanelekileyo ngokobukhulu bayo kunye nobunzima bayo ngexesha lokuthuthwa. Iindlela eziqhelekileyo zokupakisha ziquka:

Isisongelo: Intsimbi encinci ye-Angle idla ngokusongwa ngentsimbi okanye ngeteyiphu yeplastiki ukuqinisekisa ukhuseleko kunye nozinzo lwemveliso ngexesha lokuthuthwa.

Ukupakishwa kwentsimbi ye-Angle ekhandiweyo: Ukuba yintsimbi ye-Angle ekhandiweyo, izixhobo zokupakisha ezingangeni manzi nezingenamanzi, ezifana nefilimu yeplastiki engangeni manzi okanye ibhokisi engangeni manzi, zihlala zisetyenziselwa ukuthintela i-oxidation kunye nokugqwala.

Ukupakishwa komthi: Intsimbi e-engile enobukhulu okanye ubunzima obukhulu ingapakishwa ngomthi, njengeepalethi zomthi okanye iibhokisi zomthi, ukuze kubonelelwe ngenkxaso nokhuseleko olukhulu.

FAQ

1. Ndingayifumana njani ikowuteshini kuwe?

Ungasishiyela umyalezo, kwaye siza kuphendula yonke imiyalezo ngexesha elifanelekileyo.

2. Ngaba uza kuzihambisa iimpahla ngexesha elifanelekileyo?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni ophezulu kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3. Ndingafumana iisampulu ngaphambi kokuba ndi-odole?

Ewe, ewe. Ngokwesiqhelo iisampulu zethu zisimahla, singazivelisa ngeesampulu zakho okanye ngemizobo yobugcisa.

4. Ithini imiqathango yakho yokuhlawula?

Ixesha lethu lokuhlawula eliqhelekileyo yidiphozithi ye-30%, kwaye intsalela ihambelana ne-B/L. EXW, FOB, CFR, CIF.

5. Ngaba uyayamkela into yokuhlolwa ngumntu wesithathu?

Ewe siyamkela ngokupheleleyo.

6. Siyithemba njani inkampani yakho?

Siziingcali kwishishini lentsimbi kangangeminyaka emininzi njengomthengisi wegolide, ikomkhulu likwiphondo laseTianjin, samkelekile ukuphanda ngazo zonke iindlela, nangayiphi na indlela.