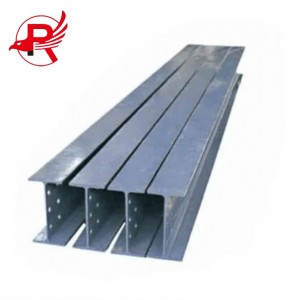

Ulwakhiwo lwentsimbi olunemilo efana ne-H lwe-EN

Umqadi we-HIntsimbi isetyenziswa kakhulu, isetyenziselwa ikakhulu: iintlobo ngeentlobo zezakhiwo zokwakha zokwakha nezokwakha; Iintlobo ngeentlobo zezityalo zoshishino ezihlala ixesha elide kunye nezakhiwo eziphakamileyo zanamhlanje, ingakumbi kwiindawo ezinomsebenzi oqhelekileyo wokunyikima kunye neemeko zokusebenza ezinobushushu obuphezulu; Iibhulorho ezinkulu ezinomthamo omkhulu wokuthwala, uzinzo oluhle lwecandelo elinqamlezileyo kunye nobubanzi obukhulu ziyafuneka; Izixhobo ezinzima; Indlela enkulu; Umqolo weenqanawa; Inkxaso yemigodi; Unyango lwesiseko kunye nobunjineli bedama; Izixhobo ezahlukeneyo zoomatshini.

INKQUBO YOKUVELISA IMVELISO

I-flange yeUmqadi we-Hiyafana okanye iphantse ifane ngaphakathi nangaphandle, kwaye isiphelo seflange sikwi-Angle esekunene, ngoko ke ibizwa ngokuba yi-parallel flange I-steel. Ubukhulu bewebhu yentsimbi enomfanekiso we-H buncinci kunobo be-I-beams eziqhelekileyo ezinokuphakama okufanayo kwewebhu, kwaye ububanzi beflange bukhulu kunobo be-I-beams eziqhelekileyo ezinokuphakama okufanayo kwewebhu, ngoko ke ikwabizwa ngokuba yi-wide-rim I-beams. Imiselwa yimo, i-section modulus, umzuzu we-inertia kunye namandla ahambelanayo e-H-beam ngokucacileyo zingcono kunobo be-I-beam eqhelekileyo enobunzima obufanayo. Isetyenziswa kwiimfuno ezahlukeneyo zesakhiwo sesinyithi, nokuba iphantsi kwe-torque egobileyo, umthwalo woxinzelelo, umthwalo ongaqhelekanga ubonisa ukusebenza kwayo okuphezulu, inokuphucula kakhulu amandla okuthwala kune-I-steel eqhelekileyo, igcina isinyithi nge-10% ~ 40%. Intsimbi enomfanekiso we-H ine-flange ebanzi, i-web encinci, iinkcukacha ezininzi, kunye nokusetyenziswa okuguquguqukayo, okunokonga i-15% ukuya kwi-20% yesinyithi kwizakhiwo ezahlukeneyo ze-truss. Ngenxa yokuba i-flange yayo ihambelana ngaphakathi nangaphandle, kwaye isiphelo somphetho sikwi-engile ekunene, kulula ukuyihlanganisa nokuyidibanisa ibe ziinxalenye ezahlukeneyo, nto leyo enokonga malunga ne-25% yomsebenzi wokuwelda kunye ne-riveting, kwaye inokukhawulezisa kakhulu isantya sokwakha seprojekthi kwaye inciphise ixesha lokwakha.

UBUKHULU BEMVELISO

| Ukutyunjwa | Unt Ubunzima kg/m) | Icandelo Eliqhelekileyo ukukhulisa mm | Icandelo UAma (cm² | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE28 | AA | 61.3 | 264.0 | 280.0 | 7.0 | 10.0 | 24.0 | 78.02 |

| A | 76.4 | 270.0 | 280.0 | 80 | 13.0 | 24.0 | 97.26 | |

| B | 103 | 280.0 | 280.0 | 10.5 | 18.0 | 24.0 | 131.4 | |

| M | 189 | 310.0 | 288.0 | 18.5 | 33.0 | 24.0 | 240.2 | |

| HE300 | AA | 69.8 | 283.0 | 300.0 | 7.5 | 10.5 | 27.0 | 88.91 |

| A | 88.3 | 200.0 | 300.0 | 85 | 14.0 | 27.0 | 112.5 | |

| B | 117 | 300.0 | 300.0 | 11.0 | 19.0 | 27.0 | 149.1 | |

| M | 238 | 340.0 | 310.0 | 21.0 | 39.0 | 27.0 | 303.1 | |

| HE320 | AA | 74.3 | 301.0 | 300.0 | 80 | 11.0 | 27.0 | 94.58 |

| A | 97.7 | 310.0 | 300.0 | 9.0 | 15.5 | 27.0 | 124.4 | |

| B | 127 | 320.0 | 300.0 | 11.5 | 20.5 | 27.0 | 161.3 | |

| M | 245 | 359.0 | 309.0 | 21.0 | 40.0 | 27.0 | 312.0 | |

| HE340 | AA | 78.9 | 320.0 | 300.0 | 85 | 11.5 | 27.0 | 100.5 |

| A | 105 | 330.0 | 300.0 | 9.5 | 16.5 | 27.0 | 133.5 | |

| B | 134 | 340.0 | 300.0 | 12.0 | 21.5 | 27.0 | 170.9 | |

| M | 248 | 377.0 | 309.0 | 21.0 | 40.0 | 27.0 | 315.8 | |

| HE360 | AA | 83.7 | 339.0 | 300.0 | 9.0 | t2.0 | 27.0 | 106.6 |

| A | 112 | 350.0 | 300.0 | 10.0 | 17.5 | 27.0 | 142.8 | |

| B | 142 | 360.0 | 300.0 | 12.5 | 22.5 | 27.0 | 180.6 | |

| M | 250 | 395.0 | 308.0 | 21.0 | 40.0 | 27.0 | 318.8 | |

| HE400 | AA | 92.4 | 3780 | 300.0 | 9.5 | 13.0 | 27.0 | 117.7 |

| A | 125 | 390.0 | 300.0 | 11.0 | 19.0 | 27.0 | 159.0 | |

| B | 155 | 400.0 | 300.0 | 13.5 | 24.0 | 27.0 | 197.8 | |

| M | 256 | 4320 | 307.0 | 21.0 | 40.0 | 27.0 | 325.8 | |

| HE450 | AA | 99.8 | 425.0 | 300.0 | 10.0 | 13.5 | 27.0 | 127.1 |

| A | 140 | 440.0 | 300.0 | 11.5 | 21.0 | 27.0 | 178.0 | |

| B | 171 | 450.0 | 300.0 | 14.0 | 26.0 | 27.0 | 218.0 | |

| M | 263 | 4780 | 307.0 | 21.0 | 40.0 | 27.0 | 335.4 | |

| Ukumisela | Iyunithi Ubunzima kg/m) | Icandelo Eliqhelekileyo Ububanzi (mm) | ICandelo Indawo (cm²) | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE50 | AA | 107 | 472.0 | 300.0 | 10.5 | 14.0 | 27.0 | 136.9 |

| A | 155 | 490.0 | 300.0 | t2.0 | 23.0 | 27.0 | 197.5 | |

| B | 187 | 500.0 | 300.0 | 14.5 | 28.0 | 27.0 | 238.6 | |

| M | 270 | 524.0 | 306.0 | 21.0 | 40.0 | 27.0 | 344.3 | |

| HE550 | AA | t20 | 522.0 | 300.0 | 11.5 | 15.0 | 27.0 | 152.8 |

| A | 166 | 540.0 | 300.0 | t2.5 | 24.0 | 27.0 | 211.8 | |

| B | 199 | 550.0 | 300.0 | 15.0 | 29.0 | 27.0 | 254.1 | |

| M | 278 | 572.0 | 306.0 | 21.0 | 40.0 | 27.0 | 354.4 | |

| HE60 | AA | t29 | 571.0 | 300.0 | t2.0 | 15.5 | 27.0 | 164.1 |

| A | 178 | 500.0 | 300.0 | 13.0 | 25.0 | 27.0 | 226.5 | |

| B | 212 | 600.0 | 300.0 | 15.5 | 30.0 | 27.0 | 270.0 | |

| M | 286 | 620.0 | 305.0 | 21.0 | 40.0 | 27.0 | 363.7 | |

| HE650 | AA | 138 | 620.0 | 300.0 | t2.5 | 16.0 | 27.0 | 175.8 |

| A | 190 | 640.0 | 300.0 | t3.5 | 26.0 | 27.0 | 241.6 | |

| B | 225 | 660.0 | 300.0 | 16.0 | 31.0 | 27.0 | 286.3 | |

| M | 293 | 668.0 | 305.0 | 21.0 | 40.0 | 27.0 | 373.7 | |

| HE700 | AA | 150 | 670.0 | 300.0 | 13.0 | 17.0 | 27.0 | 190.9 |

| A | 204 | 600.0 | 300.0 | 14.5 | 27.0 | 27.0 | 260.5 | |

| B | 241 | 700.0 | 300.0 | 17.0 | 32.0 | 27.0 | 306.4 | |

| M | 301 | 716.0 | 304.0 | 21.0 | 40.0 | 27.0 | 383.0 | |

| HE800 | AA | 172 | 770.0 | 300.0 | 14.0 | 18.0 | 30.0 | 218.5 |

| A | 224 | 790.0 | 300.0 | 15.0 | 28.0 | 30.0 | 285.8 | |

| B | 262 | 800.0 | 300.0 | 17.5 | 33.0 | 30.0 | 334.2 | |

| M | 317 | 814.0 | 303.0 | 21.0 | 40.0 | 30.0 | 404.3 | |

| HE800 | AA | 198 | 870.0 | 300.0 | 15.0 | 20.0 | 30.0 | 252.2 |

| A | 252 | 800.0 | 300.0 | 16.0 | 30.0 | 30.0 | 320.5 | |

| B | 291 | 900.0 | 300.0 | 18.5 | 35.0 | 30.0 | 371.3 | |

| M | 333 | 910.0 | 302.0 | 21.0 | 40.0 | 30.0 | 423.6 | |

| HEB1000 | AA | 222 | 970.0 | 300.0 | 16.0 | 21.0 | 30.0 | 282.2 |

| A | 272 | 0.0 | 300.0 | 16.5 | 31.0 | 30.0 | 346.8 | |

| B | 314 | 1000.0 | 300.0 | 19.0 | 36.0 | 30.0 | 400.0 | |

| M | 349 | 1008 | 302.0 | 21.0 | 40.0 | 30.0 | 444.2 | |

EI-NHIntsimbi Emile

Udidi: EN10034:1997 EN10163-3:2004

Inkcazo: I-HEA HEB kunye ne-HEM

Umgangatho: EN

IIMBONAKALO

Kukho iinkcukacha ezininzi zemvelisoUmqadi we-H, kwaye iindlela zokuhlela zezi zilandelayo.(1) Ngokwebubanzi beflengi yemveliso, yahlulwe yaba yiflange ebanzi, iflange ephakathi kunye neflange encinci ye-H-beam. Ububanzi beflangi B yeflangi ebanzi kunye neflangi ephakathi ye-H-beam bukhulu kunobude bewebhu H. Ububanzi beflangi B yentsimbi enomphetho we-H-flange encinci bulingana nesiqingatha sobude be-H yepleyiti yewebhu.(2) Ngokwendlela esetyenziswa ngayo imveliso, yahlulwe yaba yi-beam yentsimbi yohlobo lwe-H, ikholamu yentsimbi yohlobo lwe-H, inqwaba yentsimbi yohlobo lwe-H kunye ne-beam yentsimbi yohlobo lwe-H eneflangi etyebileyo kakhulu. Ngamanye amaxesha intsimbi yetshaneli yomlenze ohambelanayo kunye nentsimbi yeflangi ye-T-beam efanayo nazo zibandakanyiwe kuluhlu lwee-H-beams. Ngokubanzi, intsimbi yeflangi encinci ye-H-beam isetyenziswa njenge-beam kwaye intsimbi yeflangi ebanzi ye-H-beam isetyenziswa njengekholamu. Ngokufanelekileyo, ikwabizwa ngokuba yi-beam H-beam steel kunye ne-column H-beam steel. (3) Ngokwendlela yemveliso, yahlulwe yaba yi-welded H-beam steel kunye ne-rolled H-beam steel. (4) Ngokweenkcazo zobukhulu zahlulwe zaba yintsimbi enkulu, ephakathi nencinci enobume be-H. Ngokubanzi, iimveliso ezinobude bewebhu obungaphezulu kwe-700mm zibizwa ngokuba zikhulu, ezingama-300 ~ 700mm zibizwa ngokuba ziphakathi, kwaye ezo zingaphantsi kwe-300mm zibizwa ngokuba zincinci. Ekupheleni kowe-1990, ubude bewebhu obukhulu be-H-beam emhlabeni beyi-1200mm, ububanzi obujikelezileyo beyi-530mm.

UHLOLO LWEMVELISO

Iimfuno zokuhlolwa kwentsimbi enomfanekiso we-H ziquka ikakhulu ezi zinto zilandelayo:

Umgangatho wenkangeleko: Umgangatho wenkangeleko yentsimbi enomfanekiso we-H kufuneka uhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola. Umphezulu kufuneka ube bushelelezi kwaye uthe tyaba, ungabi nazimbobo, imikrwelo, umhlwa kunye nezinye iziphene ezicacileyo.

Ubukhulu bejometri: Ubude, ububanzi, ukuphakama, ubukhulu bewebhu, ubukhulu beflange kunye nezinye izilinganiso zentsimbi enomfanekiso we-H kufuneka zihambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola.

Ukugoba: Ukugoba kwentsimbi enomfanekiso we-H kufuneka kuhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola. Kungabonwa ngokulinganisa ukuba iiplani kuzo zombini iziphelo zentsimbi enomfanekiso we-H ziyafana okanye kusetyenziswa imitha yokugoba.

Ukujika: Ukujika kwentsimbi enomfanekiso we-H kufuneka kuhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola. Kungabonwa ngokulinganisa ukuba icala lentsimbi enomfanekiso we-H lithe nkqo okanye linemitha yokujika.

Ukuphambuka kobunzima: Ubunzima bentsimbi enomfanekiso we-H kufuneka buhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola. Ukuphambuka kobunzima kunokubonwa ngokubeka umlinganiselo.

Ukwakheka kweekhemikhali: Ukuba intsimbi enomfanekiso we-H kufuneka idityaniswe okanye icutshungulwe ngenye indlela, ukwakheka kwayo kweekhemikhali kufuneka kuhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola.

Iimpawu zoomatshini: Iimpawu zoomatshini zentsimbi enomfanekiso we-H kufuneka zihambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola, kubandakanya amandla okutsalwa, indawo yokukhupha, ukunwebeka kunye nezinye izalathisi.

Uvavanyo olungonakalisiyo: Ukuba intsimbi enomfanekiso we-H ifuna uvavanyo olungonakalisiyo, kufuneka ivavanywe ngokuhambelana nemigangatho efanelekileyo kunye neemfuno zoku-odola ukuqinisekisa ukuba umgangatho wayo wangaphakathi ulungile.

Ukupakishwa kunye nokumakishwa: Ukupakishwa kunye nokumakishwa kwentsimbi enomfanekiso we-H kufuneka kuhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola ukuze kube lula ukuthuthwa kunye nokugcinwa.

Ngamafutshane, ezi mfuno zingasentla kufuneka ziqwalaselwe ngokupheleleyo xa kuhlolwa intsimbi enomfanekiso we-H ukuqinisekisa ukuba umgangatho wayo uyahlangabezana nemigangatho efanelekileyo kunye neemfuno zoku-odola, kunye nokubonelela abasebenzisi ngeemveliso zentsimbi enomfanekiso we-H ezilungileyo.

Isicelo

OkuqhelekileyoUmqadi we-Hizixhobo zentsimbi ziquka i-Q235B, i-SM490, i-SS400, i-Q345 kunye ne-Q345B. Ulwakhiwo lweekhemikhali kunye neempawu zoomatshini zezi zinto zahlukile, ngoko ke xa ukhetha ukusebenzisa i-H-beam, kuyimfuneko ukukhetha izinto ezifanelekileyo ngokwemeko ethile.

UKUPAKISHA NOKUTHUMELA

Ukupakishwa kunye nokukhuselwa:

Ukupakisha kudlala indima ebalulekileyo ekukhuseleni umgangatho we-ASTM A36Umqadi we-Hintsimbi ngexesha lokuthuthwa nokugcinwa kwayo. Izinto ezisetyenzisiweyo mazibotshwe kakuhle, kusetyenziswa imitya okanye iibhanti ezinamandla aphezulu ukuthintela intshukumo kunye nomonakalo onokubakho. Ukongeza, kufuneka kuthathwe amanyathelo okukhusela intsimbi ekuchatshazelweni kukufuma, uthuli, kunye nezinye izinto ezingqongileyo. Ukusonga iibhanti ngezinto ezimelana nemozulu, ezifana neplastiki okanye ilaphu elingangeni manzi, kunceda ukukhusela ekungcoleni nasekugqwaleni.

FAQ

1. Ndingayifumana njani ikowuteshini kuwe?

Ungasishiyela umyalezo, kwaye siza kuphendula yonke imiyalezo ngexesha elifanelekileyo.

2. Ngaba uza kuzihambisa iimpahla ngexesha elifanelekileyo?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni ophezulu kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3. Ndingafumana iisampulu ngaphambi kokuba ndi-odole?

Ewe, ewe. Ngokwesiqhelo iisampulu zethu zisimahla, singazivelisa ngeesampulu zakho okanye ngemizobo yobugcisa.

4. Ithini imiqathango yakho yokuhlawula?

Ixesha lethu lokuhlawula eliqhelekileyo yidiphozithi ye-30%, kwaye intsalela ihambelana ne-B/L. EXW, FOB, CFR, CIF.

5. Ngaba uyayamkela into yokuhlolwa ngumntu wesithathu?

Ewe siyamkela ngokupheleleyo.

6. Siyithemba njani inkampani yakho?

Siziingcali kwishishini lentsimbi kangangeminyaka emininzi njengomthengisi wegolide, ikomkhulu likwiphondo laseTianjin, samkelekile ukuphanda ngazo zonke iindlela, nangayiphi na indlela.