Isakhiwo seNsimbi se-ASTM A36 Isakhiwo seSikole Isakhiwo seNsimbi

ISICELO

Isakhiwo seNsimbi: Iisakhiwo sentsimbiIxhaswa yintsimbi enamandla aphezulu, kwaye ineempawu zokuxhathisa ngamandla inyikima nomoya, ixesha elifutshane lokwakha kunye nendawo eguquguqukayo.

Indlu yoLwakhiwo lweNsimbi: Izakhiwo zentsimbisebenzisa uphahla lwentsimbi olukhaphukhaphu, olubonelela ngolondolozo lwamandla, ukhuseleko lokusingqongileyo, ukhuseleko lobushushu, kunye nexesha elifutshane lokwakha.

Indlu yokugcina impahla yesakhiwo sentsimbi: Isithongaisakhiwo sentsimbiinezibonelelo zobude bexesha, ukusetyenziswa kwendawo eninzi, ukwakhiwa ngokukhawuleza kunye nokubekwa kweshelufu okulula.

Isakhiwo seFektri yeSakhiwo seNsimbi: Yethuifreyimu yentsimbiIzakhiwo zefektri ziqinile kwaye ziyafumaneka kwiindawo ezibanzi ezivumela ukuba ngaphakathi kungabi nazikholam, zilungele imveliso kunye nokusetyenziswa kwemizi-mveliso.

IINKCUKACHA ZEMVELISO

Iimveliso zesakhiwo sentsimbi esingundoqo sokwakhiwa kwefektri

1. Ulwakhiwo oluphambili oluthwala umthwalo (oluhambelana neemfuno zenyikima yetropiki)

| Uhlobo lweMveliso | Uluhlu lweenkcukacha | Umsebenzi ongundoqo | Iindawo zokuZiqhelanisa eMbindi Melika |

| Umqadi weSakhelo sePortal | W12×30 ~ W16×45 (ASTM A572 Gr.50) | Umqadi oyintloko wokuthwala umthwalo eludongeni/uphahla | Uyilo lwe-seismic lwe-node ekhawulezayo kakhulu (uqhagamshelo olunamabholiti ukuthintela ukuwelda okubuthathaka), icandelo elilungiselelwe ukunciphisa ubunzima bomzimba ukuze kube lula ukuthutha kwasekuhlaleni. |

| Ikholamu yentsimbi | H300×300 ~ H500×500 (ASTM A36) | Ixhasa imithwalo yesakhelo kunye nomgangatho | Izihlanganisi ze-seismic ezifakwe emhlabeni, ezifakwe i-hot-dip galvanized (i-zinc coating ≥85μm) zokukhusela kwindawo enomswakama ophezulu |

| Umqadi weKreyini | W24×76 ~ W30×99 (ASTM A572 Gr.60) | Ukuthwala umthwalo wokusebenza kwekreyini yemizi-mveliso | Ulwakhiwo olunzima (lulungele iikhreyini ezingama-5 ~ 20t), umqadi wokugqibela ufakwe iipleyiti zokudibanisa ezingashukumiyo. |

2. Iimveliso zenkqubo yokuvala (engangeni manzi + echasene nokugqwala)

Iipurlin zophahla: C12×20~C16×31 (igqunywe nge-hot-dip galvanized), ibekwe kwindawo eyi-1.5~2m ukusuka kwenye, ifanelekile ukufakwa kwepleyiti yentsimbi enemibala, kwaye imelana nemithwalo yeenkanyamba ukuya kuthi ga kwinqanaba le-12.

Iipurlin zodonga: Z10×20~Z14×26 (ipeyintiwe ngokuchasene nokugqwala), inemingxunya yokungenisa umoya ukunciphisa ukufuma kwiifektri ezishushu.

Inkqubo yenkxaso: I-Diagonal bracing (intsimbi ejikelezileyo egqunywe nge-hot-dip galvanized Φ12~Φ16) kunye nee-corner braces (ii-engile zentsimbi L50×5) zisetyenziselwa ukonyusa uzinzo olusecaleni lwefreyimu ukumelana nemimoya enamandla evuthuzayo.

3. Ukuxhasa iimveliso ezincedisayo (uhlengahlengiso lolwakhiwo olucwangcisiweyo)

1. Iindawo ezifakiweyo: Iindawo ezifakwe kwipleyiti yentsimbi (ubude be-10mm-20mm, ezifakwe kwi-hot-dip galvanized), ezisetyenziswa kwisiseko sekhonkrithi ngokubanzi ukuze zisetyenziswe kuMbindi Melika;

2. Izihlanganisi: Iibholiti ezinamandla aphezulu (udidi 8.8, i-hot dip galvanised) akufuneki ukuwelda kwindawo kwaye ixesha lokwakha linciphile;

3. Izinto ezithintela umlilo kunye nezinto ezithintela ukubola: Ipeyinti ethintela umlilo esetyenziswa emanzini (engamelani nomlilo ≥1.5h) kunye nepeyinti ethintela ukubola ye-acrylic (engamelani ne-UV, ubomi bayo ≥10 iminyaka) ihlangabezana nesicelo sokukhusela okusingqongileyo sendawo.

UKUCUTSHUNGULWA KWESAKHIWO SENTSIMBI

| Indlela Yokucubungula | Oomatshini bokuSebenzisa | Inkcazo yokuSebenza |

|---|---|---|

| Ukusika | Oomatshini bokusika iplasma/ilangatye be-CNC, oomatshini bokucheba | Ukusikwa kweplasma/ilangatye le-CNC kwiipleyiti zentsimbi kunye namacandelo; ukucheba iipleyiti ezibhityileyo ezinomlinganiselo olawulwayo. |

| Ukwenziwa | Umatshini wokugoba obandayo, ibrake yokucinezela, umatshini wokuqengqeleka | Ukugoba okubandayo kwi-C/Z purlins, ukugoba kwii-gutters kunye nee-edge trims, ukugoba kwii-round support bars. |

| Ukuwelda | Umshiseli we-arc ofakwe emanzini, umshiseli we-arc oqhutywa ngesandla, umshiseli we-CO₂ okhuselwe yigesi | I-SAW yeekholamu ze-H kunye neebhima, ukuwelda ngesandla kwiipleyiti ze-gusset, kunye nokuwelda kwe-CO₂ kwiindawo ezineendonga ezincinci. |

| Ukwenza imingxunya | Umatshini wokugrumba we-CNC, umatshini wokubhoboza | Ukugqobhoza imingxuma yebholiti kwiipleyiti/izinto ezidibanisayo; ukubhoboza imingxuma emincinci enobubanzi obulawulwayo kunye nokuchaneka kokubekwa kwayo. |

| Unyango Lomphezulu | Umatshini wokuqhumisa/wokuqhumisa isanti, igrinder, umgca wokuntywila oshushu | Ukususa umhlwa ngokuqhumisa ngemipu/ngesanti, ukugaywa kwe-weld ukuze kususwe uburhabaxa, ukugaywa kwe-hot-dip kwiibholithi kunye neenkxaso zesakhiwo. |

| Indibano | Iqonga lokuhlanganisa, izixhobo zokulinganisa | Ukuhlanganiswa kweekholamu, imiqadi, kunye neenkxaso ngaphambi kokuba zihlanganiswe; zichithwe emva kokuqinisekiswa kobukhulu bazo ukuze zithunyelwe. |

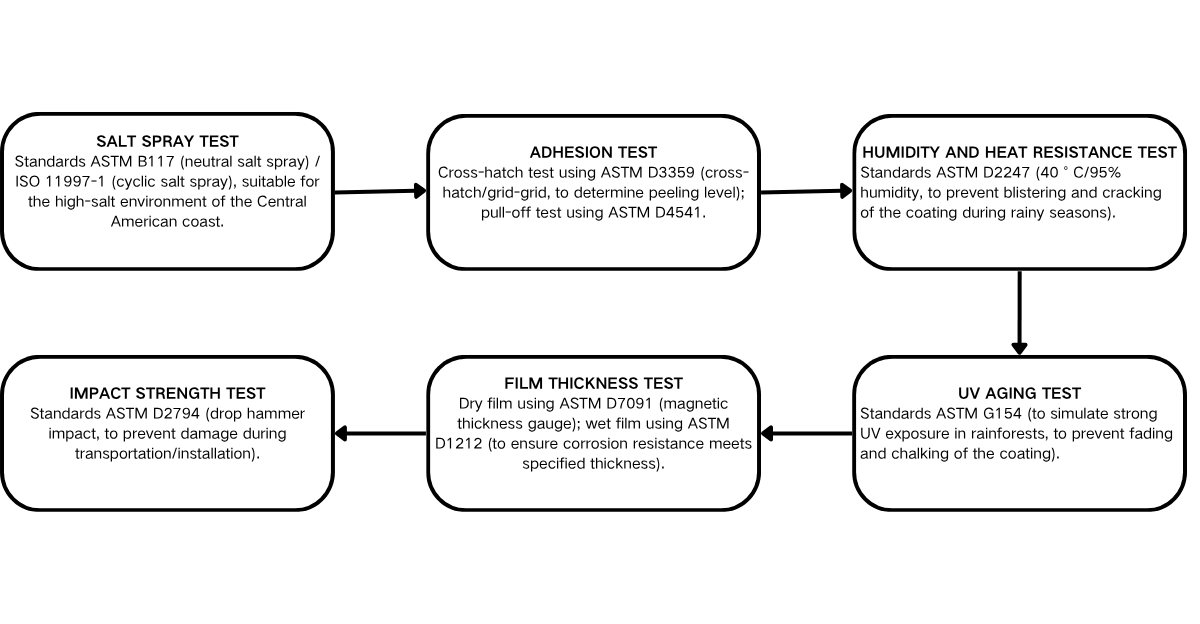

UVAVANYO LWESAKHIWO SENTSIMBI

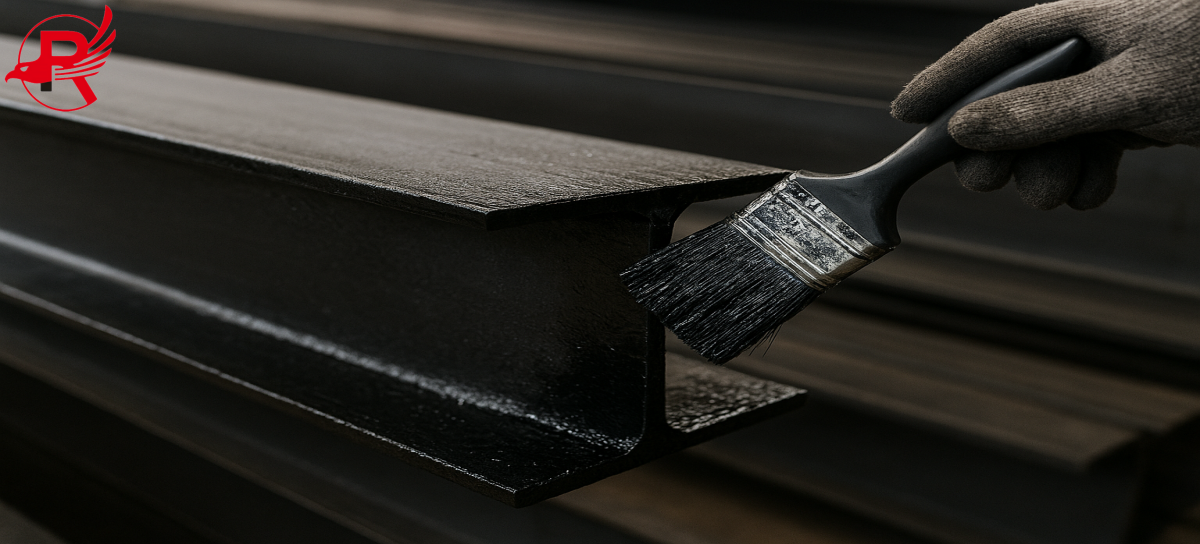

UNYANGO OLUNGEZELELWEYO

Umboniso Wonyango Lomphezulu:Ingubo etyebileyo ye-epoxy zinc, egalelwe nge-galvanized (ubude be-layer galvanized ≥85μm bunokufikelela kwiminyaka eli-15-20), efakwe i-oyile emnyama, njl.

I-Oyile Emnyama

IGQITYWE NGE-GALVANIZED

Ukwaleka okutyebileyo kwe-Epoxy Zinc

UKUPAKISHA NOKUTHUMELA

Ukupakisha:

Intsimbi ipakishwe ngokuqinileyo ukuze ikhusele umphezulu kwaye igcine ukuqina ngexesha lokuphathwa nokuthuthwa. Iimveliso zihlala zisongelwa ngezinto ezingangeni manzi, ukusonga ngeplastiki okanye iphepha elingangeni mhlwa kwaye izixhobo ezincinci zipakishwa kwiibhokisi zomthi. Zonke iibhali/iiphaneli ziphawulwe kakuhle ukuze zahlulwe, nto leyo eya kwenza kube lula ukukhupha nokufaka izinto ngokukhuselekileyo nangokufanelekileyo kwindawo leyo.

Uthutho:

Izinto zokwakha zentsimbi zithunyelwa ngesikhongozeli okanye ngenqanawa enkulu ngokwesayizi nendawo eziya kuyo. Izinto ezinzima okanye ezinkulu zifakwa ngokukhuselekileyo kwiibhokisi kusetyenziswa imitya yentsimbi kunye nokuvalwa komthi ukuthintela ukuhamba okanye umonakalo ngexesha lokuhamba. Zonke izinto zethu zothutho ziyahambelana neemfuno zothutho lwamazwe ngamazwe, ngoko ke singathembisa ukuhanjiswa ngexesha, kwaye sigcine ukhuseleko nokuba kukufutshane okanye kumgama omde kwinqanawa ehamba elwandle.

IINZUZO ZETHU

1. Amasebe aphesheya kunye neNkxaso yaseSpain

Amaqela athetha iSpanish anceda abathengi baseLatin America naseYurophu ngonxibelelwano, amasiko, amaxwebhu, kunye nokuhanjiswa kwezinto ukuze zihanjiswe ngokulula.

2. Isitokhwe Esilungele Ukuhanjiswa Ngokukhawulezileyo

Iimpahla ezinkulu ze-H beams, i-I beams, kunye neendawo zokwakha ziqinisekisa ukuba ixesha lokuqalisa lifutshane kwaye kukho ukuhanjiswa okukhawulezileyo kwiiprojekthi ezingxamisekileyo.

3. Ukupakisha koBungcali

Ukupakisha okufanelekileyo ulwandle okune-bundling yentsimbi, ukusonga okungangeni manzi, kunye nokhuseleko olusecaleni kuqinisekisa ukuthuthwa okukhuselekileyo nokungenamonakalo.

4. Ukuthunyelwa Nokuhanjiswa Okufanelekileyo

Amaqabane okuhambisa impahla athembekileyo kunye nemigaqo eguquguqukayo (i-FOB, i-CIF, i-DDP) zibonelela ngokuhanjiswa ngexesha elifanelekileyo kunye nokulandelela ngokufanelekileyo ngolwandle okanye ngololiwe.

FAQ

Ngokuphathelele uYilo lweZakhiwo kunye noKhuseleko

Q: Ngaba isakhiwo sakho sentsimbi singahlangabezana neemfuno zenyikima eMelika?

A: Ewe, uyilo lwethu lwesakhiwo sentsimbi luqwalasela iimpawu zenyikima zemimandla eyahlukeneyo eMelika.

Sisebenzisa uyilo lwamaqhuqhuva amelana ne-seismic ephezulu, njengee-bolt-connected joints, ezinokufunxa amandla e-seismic ngempumelelo kwaye ziphephe ukwaphuka kwe-welds ngexesha leenyikima. Kwangaxeshanye, siza kwenza ubalo lwe-seismic ngokweemfuno zobunzulu be-seismic yendawo ukuqinisekisa ukuba isakhiwo sentsimbi sisebenza kakuhle kwi-seismic.

Q: Uqinisekisa njani uzinzo olupheleleyo lwesakhiwo sentsimbi?

A: Uyilo lwethu lwesakhiwo sentsimbi lusekelwe kubalo olungqongqo loomatshini kunye namava obunjineli. Silungiselela ngokufanelekileyo izakhiwo eziphambili zokuthwala umthwalo, ezifana neefreyimu zesango, iikholamu, kunye neebhile zekhreyini, kwaye simisela inkqubo epheleleyo yokuxhasa, kubandakanya imivalo yokubopha kunye neebhrakhethi zekona, ukuphucula uzinzo olusecaleni lwesakhiwo kunye nokuqinisekisa ukuba isakhiwo sentsimbi sinokuthwala ngokukhuselekileyo imithwalo eyahlukeneyo phantsi kokusetyenziswa okuqhelekileyo kunye neemeko ezinzima.

Idilesi

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

I-imeyile

Ifowuni

+86 13652091506