Intsimbi Emile okwe-ASTM H iBeam iCarbon h iChannel Steel

Iinkcukacha zeMveliso

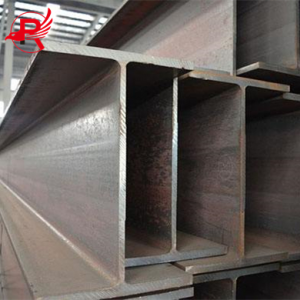

Iinkcukacha ezithile zeIntsimbi enobume obungu-HNgokwesiqhelo ziquka ubukhulu obufana nokuphakama, ububanzi beflange, ubukhulu bewebhu, kunye nobukhulu beflange. Ezi nkcukacha ziyahluka ngokusekwe kuyilo oluthile kunye nokusetyenziswa okucetywayo kwe-H-beam. Ii-H-beams ziyafumaneka ngobukhulu obahlukeneyo kunye neenkcukacha, okuvumela ukuguquguquka ekuhlangabezaneni neemfuno ezahlukeneyo zokwakha.

Ukongeza ekusetyenzisweni kwazo kwizakhiwo nakwiibhulorho,Imiqadi ye-Hzikwasetyenziswa kwizicelo ezahlukeneyo zoshishino, njengokuxhasa izixhobo ezinzima kunye noomatshini. Ukuguquguquka kunye namandla entsimbi enomfanekiso we-H kwenza kube yimfuneko ekudaleni izakhiwo kunye nezakhiwo ezizinzileyo neziqinileyo kuzo zombini iindawo zokwakha kunye nezoshishino.

| IINKCUKACHA ZEI-H-BEAM | |

| 1. Ubungakanani | 1) Ubukhulus:5-34mmokanye eyenziwe ngokwezifiso |

| 2) Ubude:6-12m | |

| 3) Ubukhulu bewebhu:6mm-16mm | |

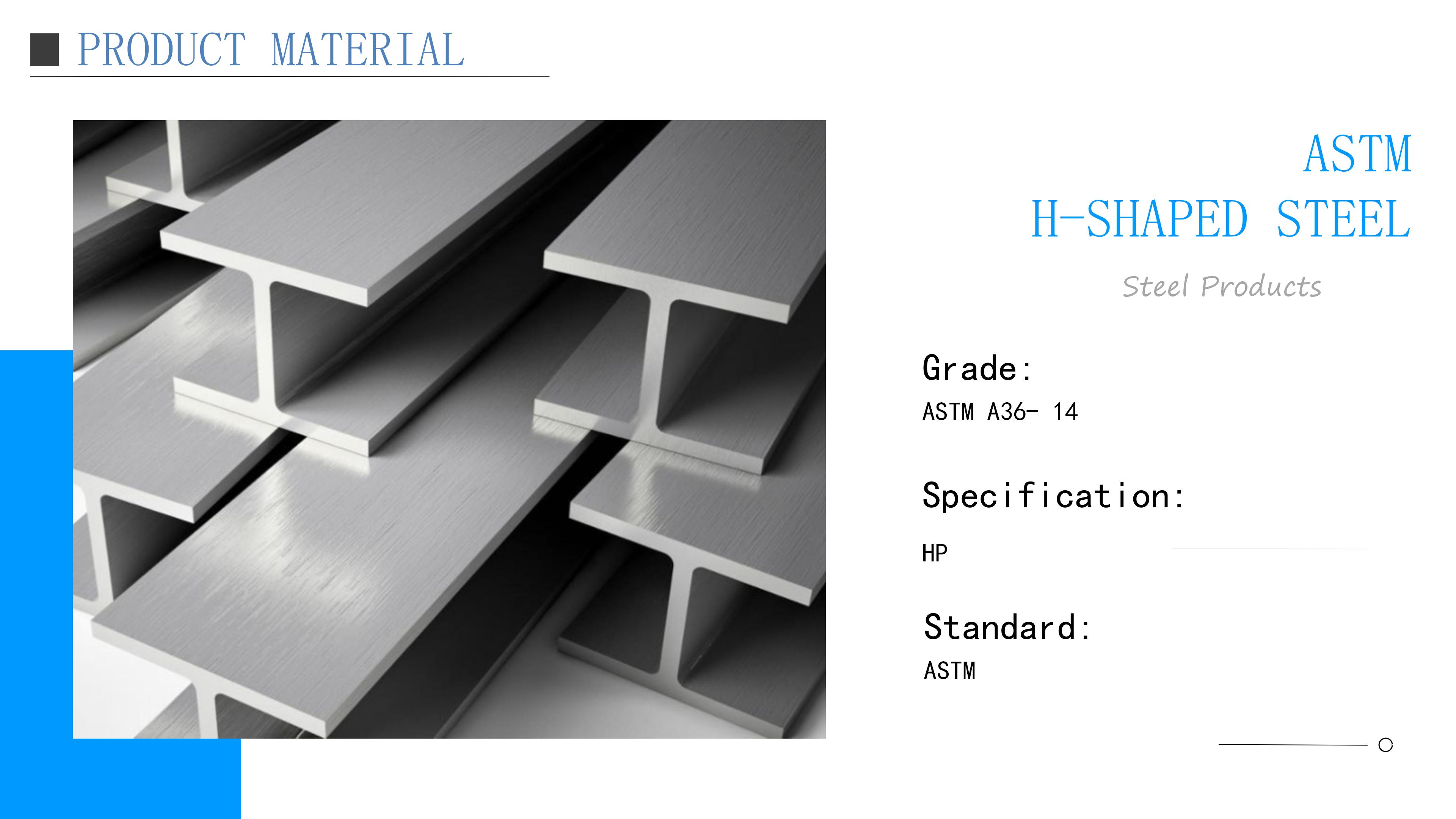

| 2. Umgangatho: | JIS ASTM DIN EN GB |

| 3. Izinto eziphathekayo | Q195 Q235 Q345 A36 S235JR S335JR |

| 4. Indawo yefektri yethu | eTianjin, eTshayina |

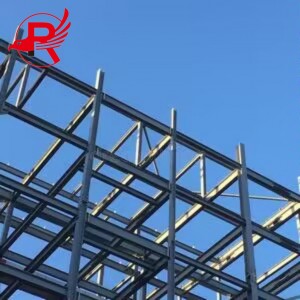

| 5. Ukusetyenziswa: | 1) isakhiwo esiphakamileyo semizi-mveliso |

| 2) Izakhiwo kwiindawo ezisengozini yokuhlaselwa yinyikima | |

| 3) iibhulorho ezinkulu ezinee-span ezinde | |

| 6. Ukwaleka: | 1) Uhluthwe 2) Ipeyinti emnyama (i-varnish coating) 3) i-galvanized |

| 7. Indlela yokusebenza: | hot roll |

| 8. Uhlobo: | Inqwaba yeshiti yohlobo lwe-H |

| 9. Imilo yeCandelo: | H |

| 10. Uhlolo: | Ukuhlolwa okanye ukuhlolwa komthengi ngumntu wesithathu. |

| 11. Ukuhanjiswa: | Isitya, Isitya Esininzi. |

| 12. Malunga noMgangatho wethu: | 1) Akukho monakalo, akukho kugoba 2) Isimahla ukuba ifakwe ioyile kunye nokumakisha 3) Zonke iimpahla zingajongwa ngokuhlolwa ngumntu wesithathu ngaphambi kokuba zithunyelwe |

| UDivis ibn (ubunzulu x idth | Iyunithi Ubunzima kg/m) | I-Sandard Sectional Ubukhulu (mm) | Icandelo Indawo cm² | ||||

| W | H | B | 1 | 2 | r | A | |

| HP8x8 | 53.5 | 203.7 | 207.1 | 11.3 | 11.3 | 10.2 | 68.16 |

| HP10x10 | 62.6 | 246.4 | 255.9 | 10.5 | 10.7 | t2.7 | 70.77 |

| 85.3 | 253.7 | 259.7 | 14.4 | 14.4 | 127 | 108.6 | |

| HP12x12 | 78.3 | 2992 | 305.9 | 11.0 | 11.0 | 15.2 | 99.77 |

| 93.4 | 303.3 | 308.0 | 13.1 | 13.1 | 15.2 | 119.0 | |

| 111 | 308.1 | 310.3 | 15.4 | 15.5 | 15.2 | 140.8 | |

| 125 | 311.9 | 312.3 | 17.4 | 17.4 | 15.2 | 158.9 | |

| HP14x14% | 108.0 | 345.7 | 370.5 | 12.8 | t2.8 | 15.2 | 137.8 |

| 132.0 | 351.3 | 373.3 | 15.6 | 15.6 | 15.2 | 168.4 | |

| 152.0 | 355.9 | 375.5 | 17.9 | 17.9 | 15.2 | 193.7 | |

| 174.0 | 360.9 | 378.1 | 20.4 | 20.4 | 15.2 | 221.5 | |

Iimbonakalo

Intsimbi enobume obungu-HKwinkqubo yokupakisha nokuthutha, kufuneka kuqwalaselwe le mibandela ilandelayo:

Ukupakisha: Intsimbi enobume obungu-Hkufuneka zipakishwe kakuhle ngaphambi kokuba zithuthwe ukuze kuthintelwe umonakalo kumphezulu. Izinto zokupakisha eziqhelekileyo ziquka iipallet zomthi, iibhokisi zomthi, ukupakisha kweplastiki njalo njalo. Izinto zokupakisha kufuneka zomelele kwaye zizinzile ngokwaneleyo ukuqinisekisa ukuba intsimbi enomfanekiso we-H ayizukucinezelwa okanye ingqubeke xa kuthuthwa.

Ukumakisha:Ubunzima, ubungakanani, imodeli kunye nolunye ulwazi lweIntsimbi enobume obungu-Hkufuneka iphawulwe ngokucacileyo kwiphakheji ukuze kube lula ukuchongwa ngexesha lokuthuthwa nokusetyenziswa.

Ukuphakamisa nokuphatha:Xa uphakamisa kwaye uphatha ii-H-beams, kufuneka izixhobo zokuphakamisa ezifanelekileyo kunye neehoko ukuqinisekisa ukusebenza okukhuselekileyo nokuzinzileyo.

Uthutho:Khetha iindlela ezifanelekileyo zokuthutha ukuqinisekisa ukuba intsimbi enomfanekiso we-H ayizukungcangcazela kakhulu ngexesha lokuthuthwa.

Isicelo

Izicelo zeImiqadi yeCandelo le-H:

Ukuguquguquka kwemiqadi yecandelo le-H kuyenza ibe yeyona nto ibalulekileyo kwiiprojekthi ezininzi zokwakha. Imiqadi yecandelo le-H isebenza njengezinto eziphambili zokwakha ekwakhiweni kweebhulorho, inika umqolo wobude obuqinileyo nobuhlala ixesha elide. Ukukwazi kwazo ukumelana nemithwalo enzima kunye nokumelana namandla asecaleni kuzenza zibe zilungele izakhiwo eziphakamileyo, ukuqinisekisa uzinzo kunye nokwamkela imingxuma emikhulu yomgangatho. Ukongeza,Imiqadi yecandelo le-Hfumana usetyenziso kwiindawo zoshishino, ukuxhasa oomatshini abanzima kunye nokubonelela ngendawo yokugcina izinto ephakamileyo.

Imiqadi yecandelo le-HZikwasetyenziswa kakhulu kwishishini lokwakha iinqanawa, apho amandla azo aphezulu okuthwala umthwalo kunye nokumelana nokugqwala kuzenza zibe zilungele ukwakha izakhiwo ezahlukeneyo zaselwandle. Ngaphezu koko, uyilo lwezakhiwo zanamhlanje ludla ngokusebenzisa imiqadi ye-H section njengezinto zoyilo ezithandekayo, zongeza ukuchukumisa kwemizi-mveliso kwizakhiwo zanamhlanje.

Ukupakishwa kunye nokuthunyelwa

Ukupakisha:

Beka iimfumba zamaphepha ngokuqinileyo: LungisaUmqadi we-Hkwinqwaba ecocekileyo nezinzileyo, ukuqinisekisa ukuba zilungelelaniswe kakuhle ukuthintela naluphi na ungazinzi. Sebenzisa intambo okanye ibhandeji ukuqinisa inqwaba kwaye uthintele ukushukuma ngexesha lokuthuthwa.

Sebenzisa izinto zokukhusela ukupakisha: Songa inqwaba yeengqokelela zamaphepha ngezinto ezingangenisi manzi, ezifana neplastiki okanye iphepha elingangeni manzi, ukuze uzikhusele ekuchatshazelweni ngamanzi, ukufuma, kunye nezinye izinto ezingqongileyo. Oku kuya kunceda ukuthintela ukugqwala nokubola.

Ukuhambisa ngenqanawe:

Khetha indlela efanelekileyo yokuthutha: Ngokuxhomekeke kubungakanani kunye nobunzima beenqwaba zeeshiti, khetha indlela efanelekileyo yokuthutha, njengeelori ezisicaba, iikhonteyina, okanye iinqanawa. Cinga ngezinto ezifana nomgama, ixesha, iindleko, kunye nazo naziphi na iimfuno zomthetho zokuthutha.

Sebenzisa izixhobo zokuphakamisa ezifanelekileyo: Ukulayisha nokukhululaIinqwaba zesinyithi zentsimbi ezimile okwe-U, sebenzisa izixhobo zokuphakamisa ezifanelekileyo ezifana neekhreyini, iiforklift, okanye ii-loaders. Qinisekisa ukuba izixhobo ezisetyenzisiweyo zinamandla aneleyo okuphatha ubunzima beenqwaba zeeshiti ngokukhuselekileyo.

Qinisa umthwalo: Qinisa ngokufanelekileyo isitaki esipakishiweyoiinqwaba zamaphephakwisithuthi sokuthutha usebenzisa intambo, i-bracing, okanye ezinye iindlela ezifanelekileyo zokuthintela ukushukuma, ukutyibilika, okanye ukuwa ngexesha lokuhamba.

FAQ

1. Ndingayifumana njani ikowuteshini kuwe?

Ungasishiyela umyalezo, kwaye siza kuphendula yonke imiyalezo ngexesha elifanelekileyo.

2. Ngaba uza kuzihambisa iimpahla ngexesha elifanelekileyo?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni ophezulu kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3. Ndingafumana iisampulu ngaphambi kokuba ndi-odole?

Ewe, ewe. Ngokwesiqhelo iisampulu zethu zisimahla, singazivelisa ngeesampulu zakho okanye ngemizobo yobugcisa.

4. Ithini imiqathango yakho yokuhlawula?

Ixesha lethu lokuhlawula eliqhelekileyo yidiphozithi ye-30%, kwaye intsalela ihambelana ne-B/L. EXW, FOB, CFR, CIF.

5. Ngaba uyayamkela into yokuhlolwa ngumntu wesithathu?

Ewe siyamkela ngokupheleleyo.

6. Siyithemba njani inkampani yakho?

Siziingcali kwishishini lentsimbi kangangeminyaka emininzi njengomthengisi wegolide, ikomkhulu likwiphondo laseTianjin, samkelekile ukuphanda ngazo zonke iindlela, nangayiphi na indlela.