Ipleyiti yentsimbi yekhabhoni ethambileyo ye-ASTM A283 yebanga / i-6mm etyebileyo yesinyithi sentsimbi egayiweyo

Iinkcukacha zeMveliso

Ishidi lesinyithiIbhekisa kwishiti yentsimbi egqunywe ngomaleko we-zinc phezu komphezulu. I-Galvanizing yindlela yokuthintela umhlwa engabizi kakhulu nesebenzayo esetyenziswa rhoqo, kwaye malunga nesiqingatha semveliso ye-zinc ehlabathini isetyenziswa kule nkqubo.

Ngokweendlela zokuvelisa kunye nokucubungula, ingahlulwahlulwa ibe ziindidi ezilandelayo:

Ishidi lesinyithi eligqunywe ngentsimbi eshushu. Nciphisa ipleyiti yesinyithi ebhityileyo kwi-zinc tank etyhidiweyo ukuze wenze ipleyiti yesinyithi ebhityileyo enomaleko we-zinc enamathele kumphezulu wayo. Okwangoku, inkqubo eqhubekayo yokwenza i-galvanizing isetyenziselwa kakhulu ukuvelisa, oko kukuthi, ipleyiti yesinyithi ebhityileyo iqhubeka intywiliselwa kwi-galvanizing tank ene-zinc etyhidiweyo ukwenza ipleyiti yesinyithi etyhidiweyo;

Intsimbi egalelweyo eyenziwe nge-alloy. Olu hlobo lwentsimbi lukwaveliswa kusetyenziswa indlela ye-hot-dip galvanizing, kodwa ifudunyezwa ngoko nangoko ukuya kuthi ga kwi-500°C emva kokuphuma etankini ukuze yenze ifilimu ye-zinc-iron alloy. Olu hlobo lwentsimbi egalelweyo lubonisa ukunamathela okuhle kwepeyinti kunye nokudityaniswa.

Intsimbi egayiweyo nge-electrogalvanized. Intsimbi egayiweyo eyenziwe kusetyenziswa indlela ye-electroplating inika ukusebenza okugqwesileyo, kodwa ulusu luncinci kwaye ukumelana nokugqwala kwalo kungaphantsi kolu lwentsimbi egayiweyo eshushu.

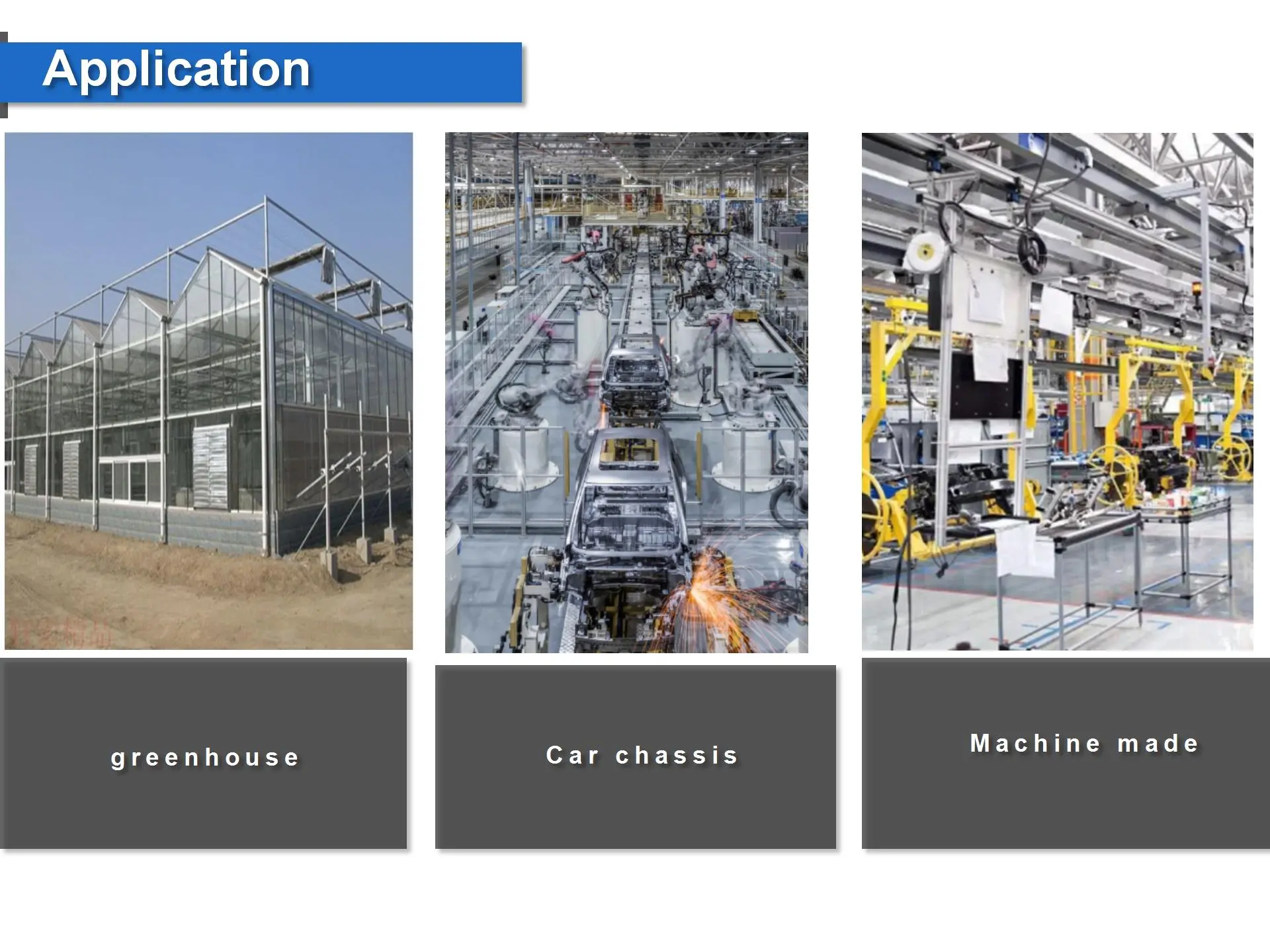

Isicelo Esiphambili

Iimbonakalo

1. Ukumelana nokugqwala, ukupeyinta, ukwakheka kakuhle, kunye nokudityaniswa kwamabala.

2. Isetyenziswa kakhulu, ikakhulu kwiindawo ezincinci zezixhobo ezifuna ubuhle obuphezulu. Nangona kunjalo, ibiza kakhulu kune-SECC, nto leyo ekhokelela ekubeni abavelisi abaninzi batshintshele kwi-SECC ukuze bonge iindleko.

3. Ukwahlula ngokwemaleko ye-zinc: Ubungakanani bee-zinc spangles kunye nobukhulu beleko ye-zinc bubonakalisa umgangatho wenkqubo yokugaya i-galvanizing; okukhona ii-spangles zincinci kwaye umaleko we-zinc utyebile, kokukhona kungcono. Abavelisi banokongeza unyango oluchasene nokuprintwa kweminwe. Ukongeza, amanqanaba anokwahlulwa ngokwemaleko yokugquma; umzekelo, i-Z12 ibonisa ukugquma okupheleleyo kwe-120g/mm kumacala omabini.

Isicelo

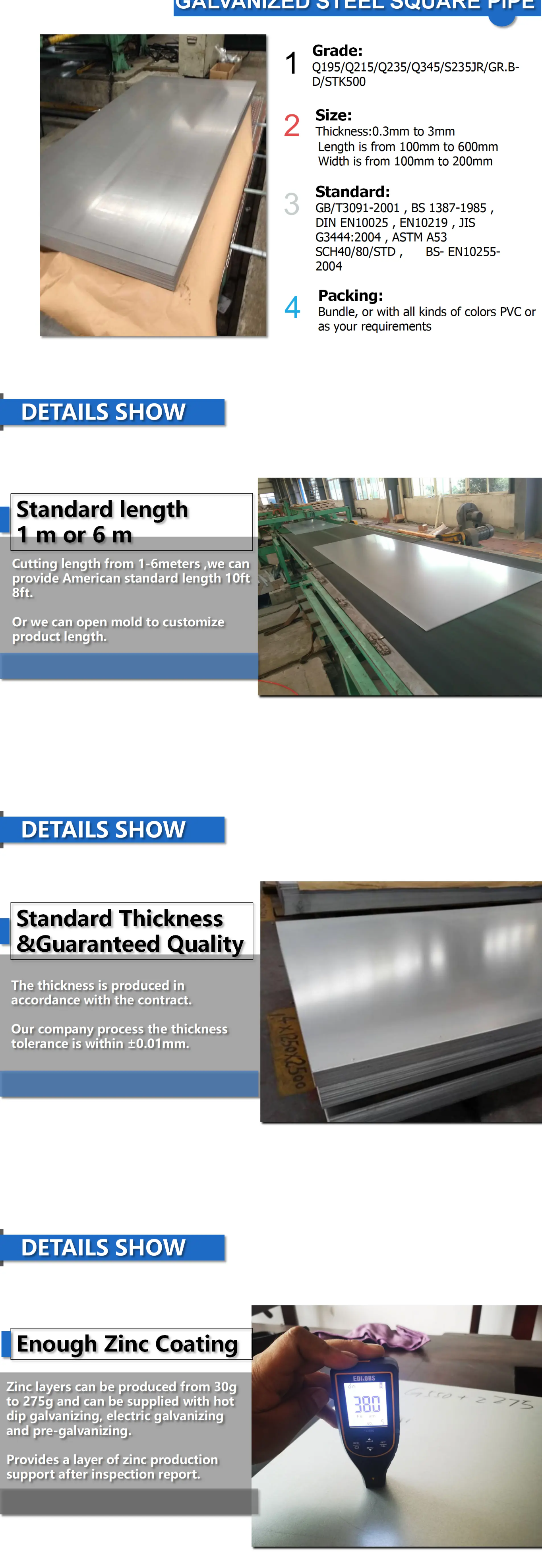

Iiparameters

| Umgangatho woBugcisa | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Ibanga lentsimbi | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), I-SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); okanye uMthengi Imfuneko |

| Ubukhulu | imfuneko yomthengi |

| Ububanzi | ngokweemfuno zomthengi |

| Uhlobo lokugquma | Intsimbi Eshushu Etyibiliziweyo (HDGI) |

| Ukwaleka kweZinc | 30-275g/m2 |

| Unyango Lomphezulu | Ukudlulisa (C), Ukufaka ioyile (O), ukutywina kweLacquer (L), iPhosphating (P), Ukunganyangwa (U) |

| Ulwakhiwo lomphezulu | Ingubo eqhelekileyo ye-spangle (NS), i-spangle coating encinci (MS), i-spangle-free (FS) |

| Umgangatho | Ivunyiwe yi-SGS, ISO |

| ID | 508mm/610mm |

| Ubunzima bekhoyili | Iitoni ezi-3-20 zemitha nganye ngekhoyili |

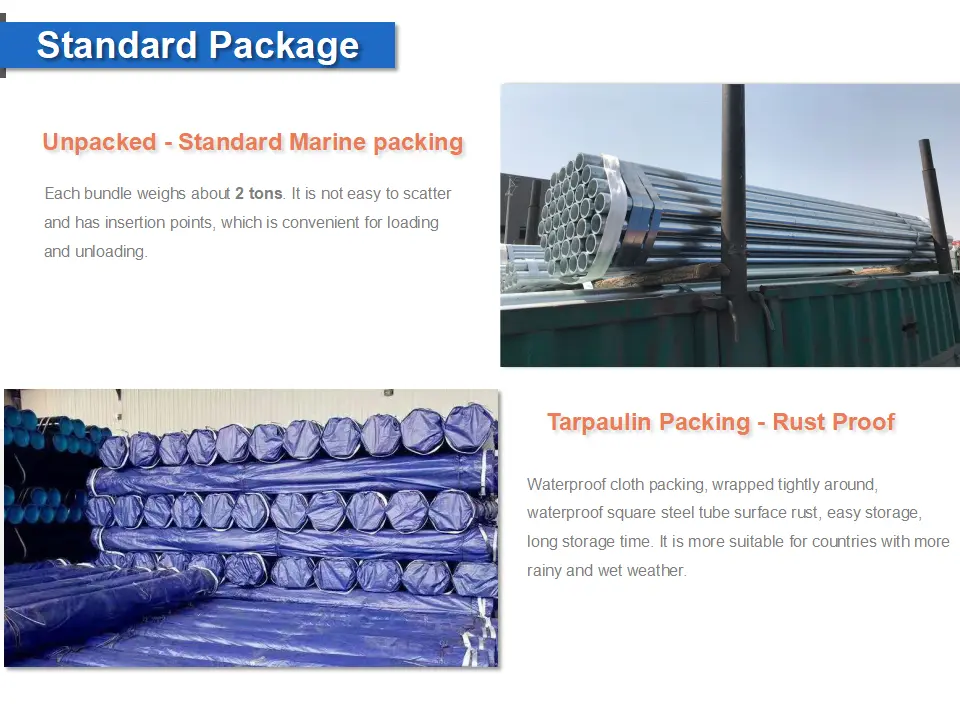

| Iphakheji | Iphepha elingangeni manzi lipakishwe ngaphakathi, intsimbi eqinisiweyo okanye iphepha lesinyithi eligqunyiweyo lipakishwe ngaphandle, ipleyiti yonogada esecaleni, emva koko isongwe ibhande lentsimbi ezisixhenxe. okanye ngokweemfuno zomthengi |

| Imakethi yokuthumela ngaphandle | IYurophu, iAfrika, iAsia Ephakathi, uMzantsi-mpuma weAsia, uMbindi Mpuma, uMzantsi Melika, uMntla Melika, njl. |

Dei-livery

FAQ

Q: Ngaba ngaba ngumvelisi we-ua?

A: Ewe, singabenzi bemveliso. Sinefektri yethu ekwiSixeko saseTianjin, eTshayina.

Q: Ndingafumana iodolo yovavanyo lweetoni ezimbalwa kuphela?

A: Ewe. Singakuthumela umthwalo ngenkonzo ye-LCL. (Umthwalo wesikhongozeli omncinci)

Q: Ukuba isampuli ayifumaneki?

A: Akukho sampuli, kodwa umthengi uhlawulela umthwalo.

Q: Ingaba ungumboneleli wegolide kwaye uqinisekisa urhwebo?

A: Singumthengisi wegolide weminyaka esixhenxe kwaye samkela isiqinisekiso sorhwebo.