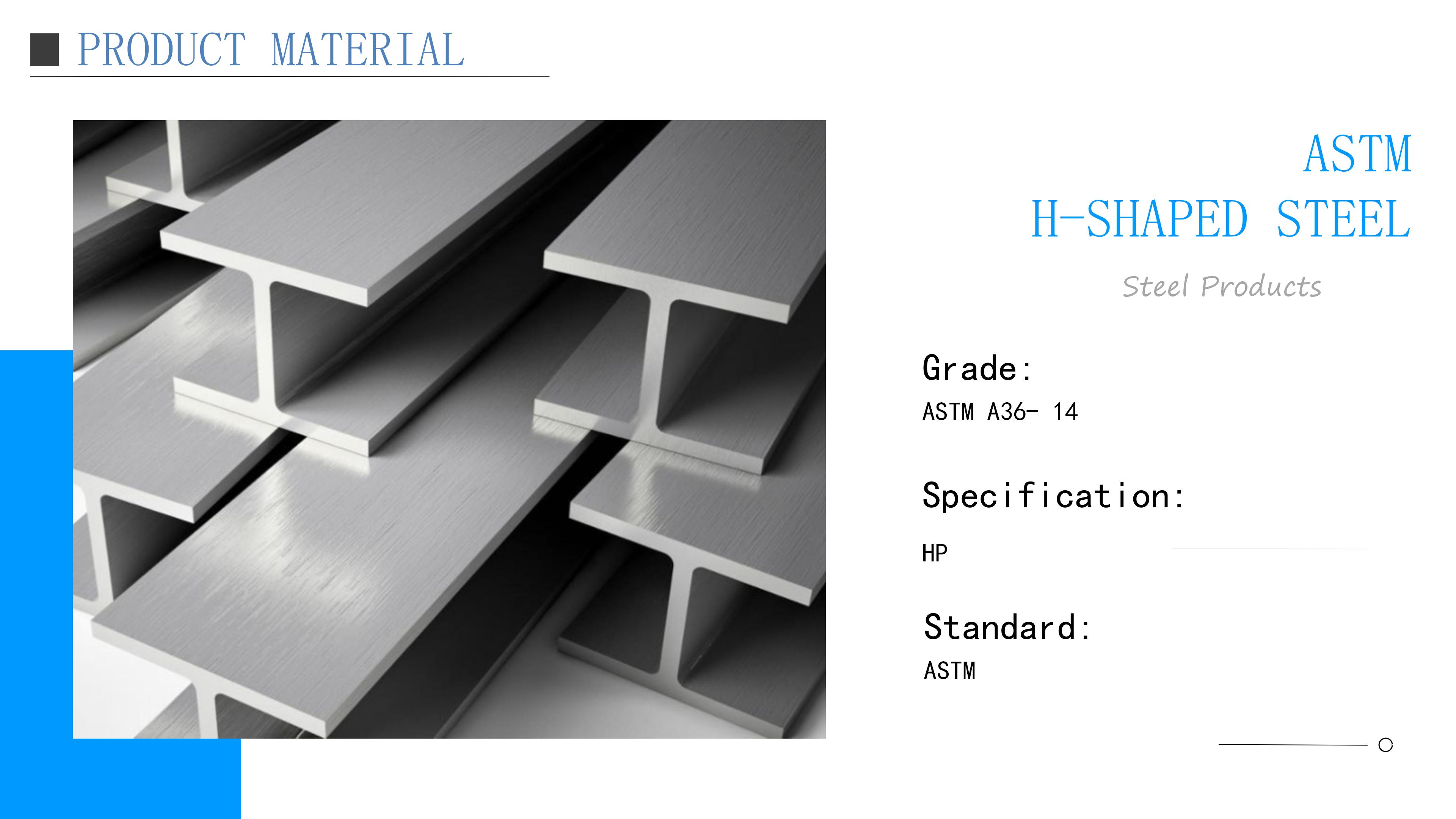

Iprofayili yentsimbi yekhabhoni yentsimbi ye-200x100x5.5×8 150x150x7x10 125×125 ASTM enemilo efana ne-H yentsimbi ye-carbon eyenziwe nge-ASTM i-H Beam

Ngenxa yokuba zonke iindawo zeUmqadi HZibekwe kwiikona zasekunene, intsimbi ye-I-beam inokumelana okukhulu nokugoba kuzo zonke iindlela, isakhiwo sayo silula, ubunzima bayo bulula, ukwakhiwa kwayo kunye neendleko, njl.njl., isetyenziswa kakhulu.

INKQUBO YOKUVELISA IMVELISO

1. Ukulungiselela kwangaphambili: kubandakanya ukuthengwa kwezinto eziluhlaza, ukuhlolwa komgangatho kunye nokulungiswa kwezinto. Izinto eziluhlaza zihlala ziyintsimbi enyibilikisiweyo eyenziwe ngokwenza isinyithi esifubeni segrafitisation esikumgangatho ophezulu okanye ukwenza isinyithi esifubeni sombane, esifakwa kwimveliso emva kokuhlolwa komgangatho.

2. Ukunyibilikisa: Galela intsimbi enyibilikisiweyo kwi-converter uze wongeze intsimbi yentsimbi okanye yehagu efanelekileyo ukuze kwenziwe intsimbi. Ngexesha lenkqubo yokwenza intsimbi, umxholo wekhabhoni kunye nobushushu bentsimbi enyibilikisiweyo kulawulwa ngokulungelelanisa umthamo we-graphitizing agent kunye nokuvuthela ioksijini kwi-oven.

3. I-billet yokuphosa eqhubekayo: I-billet yokwenza intsimbi igalelwa kumatshini wokuphosa oqhubekayo, kwaye amanzi aphuma kumatshini wokuphosa oqhubekayo afakwa kwi-crystallizer, okuvumela intsimbi enyibilikisiweyo ukuba iqine kancinci kancinci ukuze yenze i-billet.

4. Ukuqengqeleka okushushu: I-billet eqhubekayo yokuphosa iqengqeleka ngokushushu kwiyunithi yokuqengqeleka okushushu ukuze ifikelele kubungakanani obuchaziweyo kunye nemilo yejiyometri.

5. Ukuqengqeleka okugqityiweyo: I-billet eqengqelekayo eshushu igqityiwe ukuqengqeleka, kwaye ubungakanani kunye nokuma kwe-billet kwenziwa kube ngokuchanekileyo ngokulungelelanisa iiparameter ze-rolling mill kunye nokulawula amandla okuqengqeleka.

6. Ukupholisa: Intsimbi egqityiweyo iyapholiswa ukuze kuncitshiswe ubushushu kwaye kulungiswe ubukhulu kunye neempawu.

7. Ukuhlolwa komgangatho kunye nokupakishwa: Ukuhlolwa komgangatho weemveliso ezigqityiweyo kunye nokupakishwa ngokweemfuno zobungakanani kunye nobungakanani.

UBUKHULU BEMVELISO

| IINKCUKACHA ZEI-H-BEAM | |

| 1. Ubungakanani | 1) Ubukhulus:5-34mmokanye eyenziwe ngokwezifiso |

| 2) Ubude:6-12m | |

| 3) Ubukhulu bewebhu:6mm-16mm | |

| 2. Umgangatho: | JIS ASTM DIN EN GB |

| 3. Izinto eziphathekayo | Q195 Q235 Q345 A36 S235JR S335JR |

| 4. Indawo yefektri yethu | eTianjin, eTshayina |

| 5. Ukusetyenziswa: | 1) isakhiwo esiphakamileyo semizi-mveliso |

| 2) Izakhiwo kwiindawo ezisengozini yokuhlaselwa yinyikima | |

| 3) iibhulorho ezinkulu ezinee-span ezinde | |

| 6. Ukwaleka: | 1) Uhluthwe 2) Ipeyinti emnyama (i-varnish coating) 3) i-galvanized |

| 7. Indlela yokusebenza: | hot roll |

| 8. Uhlobo: | Inqwaba yeshiti yohlobo lwe-H |

| 9. Imilo yeCandelo: | H |

| 10. Uhlolo: | Ukuhlolwa okanye ukuhlolwa komthengi ngumntu wesithathu. |

| 11. Ukuhanjiswa: | Isitya, Isitya Esininzi. |

| 12. Malunga noMgangatho wethu: | 1) Akukho monakalo, akukho kugoba 2) Isimahla ukuba ifakwe ioyile kunye nokumakisha 3) Zonke iimpahla zingajongwa ngokuhlolwa ngumntu wesithathu ngaphambi kokuba zithunyelwe |

| UDivis ibn (ubunzulu x idth | Iyunithi Ubunzima kg/m) | I-Sandard Sectional Ubukhulu (mm) | Icandelo Indawo cm² | ||||

| W | H | B | 1 | 2 | r | A | |

| HP8x8 | 53.5 | 203.7 | 207.1 | 11.3 | 11.3 | 10.2 | 68.16 |

| HP10x10 | 62.6 | 246.4 | 255.9 | 10.5 | 10.7 | t2.7 | 70.77 |

| 85.3 | 253.7 | 259.7 | 14.4 | 14.4 | 127 | 108.6 | |

| HP12x12 | 78.3 | 2992 | 305.9 | 11.0 | 11.0 | 15.2 | 99.77 |

| 93.4 | 303.3 | 308.0 | 13.1 | 13.1 | 15.2 | 119.0 | |

| 111 | 308.1 | 310.3 | 15.4 | 15.5 | 15.2 | 140.8 | |

| 125 | 311.9 | 312.3 | 17.4 | 17.4 | 15.2 | 158.9 | |

| HP14x14% | 108.0 | 345.7 | 370.5 | 12.8 | t2.8 | 15.2 | 137.8 |

| 132.0 | 351.3 | 373.3 | 15.6 | 15.6 | 15.2 | 168.4 | |

| 152.0 | 355.9 | 375.5 | 17.9 | 17.9 | 15.2 | 193.7 | |

| 174.0 | 360.9 | 378.1 | 20.4 | 20.4 | 15.2 | 221.5 | |

IIMBONAKALO

Umqadi we-H 100x100ingasetyenziselwa ikakhulu uphuhliso lweebhari kunye neekholamu kwizakhiwo zemizi-mveliso kunye nezoluntu.

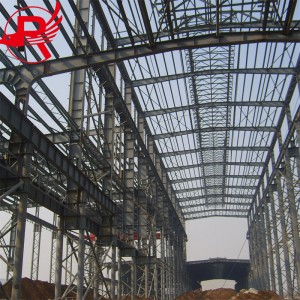

Isibiyeli sentsimbi Ulwakhiwo lweshishini. Iinqwaba zentsimbi kunye nezakhiwo ezixhasayo Imisebenzi engaphantsi komhlaba Amandla epetroli kunye nombane kunye nezinye izixhobo zemveliso yeshishini Isakhiwo sezixhobo ezinkulu zebhulorho yentsimbi Inqanawa, oomatshini Ulwakhiwo lwesakhelo Uloliwe, imoto, ibhrekhi yetrektara Izibuko lixhaswa yibhanti yokuhambisa kunye ne-baffle yesantya esiphezuluXa kufikwa ekuxhaseni imithwalo enzima, i-H Beam Pile ngokungathandabuzekiyo iyaphuma kukhuphiswano. Umqadi wentsimbi yesakhiwo i-H ubonisa iimpawu zamandla ezimangalisayo, nto leyo eyenza ukuba ibe lukhetho olufanelekileyo kwiiprojekthi apho amandla okuthwala umthwalo ebaluleke kakhulu. Ukongeza, ukusetyenziswa kwentsimbi eqengqelekayo eshushu kwinkqubo yokuvelisa kuphucula ukuqina kunye nokuqina kwale miqadi, okwenza ukuba imelane kakhulu nokugoba, ukujija, kunye nokugqwala.

IPROJEKTHI

Inkampani yethu inamava eminyaka emininzi kurhwebo lwangaphandle lweI-Hot Rolled Steel H Beam. Isixa-mali esipheleleyo see-H-beams ezithunyelwa eKhanada ngeli xesha singaphezulu kwe-8,000,000 yeetoni. Umthengi uza kuhlola iimpahla ezikwifektri. Nje ukuba iimpahla ziphumelele uhlolo, intlawulo iya kwenziwa kwaye ithunyelwe. Ukususela oko kwaqala ukwakhiwa kwale projekthi, inkampani yethu ilungiselele ngononophelo isicwangciso semveliso kwaye yaqokelela ukuhamba kwenkqubo ukuqinisekisa ukuhanjiswa ngexesha elifanelekileyo kweprojekthi yentsimbi enomfanekiso we-H. Ekubeni isetyenziswa kwizakhiwo ezinkulu zefektri, iimfuno zokusebenza kweemveliso zentsimbi enomfanekiso we-H ziphezulu kunokumelana nokugqwala kwentsimbi enomfanekiso we-H yeqonga leoyile. Ke ngoko, inkampani yethu iqala kumthombo wemveliso kwaye yonyusa ulawulo lokwenza intsimbi, ukuphoswa okuqhubekayo kunye neenkqubo ezinxulumene nokuqengqeleka. Yomeleza umgangatho weemveliso zeenkcukacha ezahlukeneyo ukuze zilawulwe ngokufanelekileyo kuzo zonke iinkalo, ukuqinisekisa izinga lokupasa le-100% leemveliso ezigqityiweyo. Ekugqibeleni, umgangatho wokucubungula intsimbi enomfanekiso we-H waqatshelwa ngabathengi ngazwi linye, kwaye intsebenziswano yexesha elide kunye neenzuzo zamazwe ngamazwe zafezekiswa ngokusekelwe ekuthembekeni.

UHLOLO LWEMVELISO

Iimfuno zokuhlolwa kwentsimbi enomfanekiso we-H ziquka ikakhulu ezi zinto zilandelayo:

Umgangatho wenkangeleko: Umgangatho wenkangeleko yentsimbi enomfanekiso we-H kufuneka uhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola. Umphezulu kufuneka ube bushelelezi kwaye uthe tyaba, ungabi nazimbobo, imikrwelo, umhlwa kunye nezinye iziphene ezicacileyo.

Ubukhulu bejometri: Ubude, ububanzi, ukuphakama, ubukhulu bewebhu, ubukhulu beflange kunye nezinye izilinganiso zentsimbi enomfanekiso we-H kufuneka zihambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola.

Ukugoba: Ukugoba kwentsimbi enomfanekiso we-H kufuneka kuhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola. Kungabonwa ngokulinganisa ukuba iiplani kuzo zombini iziphelo zentsimbi enomfanekiso we-H ziyafana okanye kusetyenziswa imitha yokugoba.

Ukujika: Ukujika kwentsimbi enomfanekiso we-H kufuneka kuhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola. Kungabonwa ngokulinganisa ukuba icala lentsimbi enomfanekiso we-H lithe nkqo okanye linemitha yokujika.

Ukuphambuka kobunzima: Ubunzima bentsimbi enomfanekiso we-H kufuneka buhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola. Ukuphambuka kobunzima kunokubonwa ngokubeka umlinganiselo.

Ukwakheka kweekhemikhali: Ukuba intsimbi enomfanekiso we-H kufuneka idityaniswe okanye icutshungulwe ngenye indlela, ukwakheka kwayo kweekhemikhali kufuneka kuhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola.

Iimpawu zoomatshini: Iimpawu zoomatshini zentsimbi enomfanekiso we-H kufuneka zihambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola, kubandakanya amandla okutsalwa, indawo yokukhupha, ukunwebeka kunye nezinye izalathisi.

Uvavanyo olungonakalisiyo: Ukuba intsimbi enomfanekiso we-H ifuna uvavanyo olungonakalisiyo, kufuneka ivavanywe ngokuhambelana nemigangatho efanelekileyo kunye neemfuno zoku-odola ukuqinisekisa ukuba umgangatho wayo wangaphakathi ulungile.

Ukupakishwa kunye nokumakishwa: Ukupakishwa kunye nokumakishwa kwentsimbi enomfanekiso we-H kufuneka kuhambelane nemigangatho efanelekileyo kunye neemfuno zoku-odola ukuze kube lula ukuthuthwa kunye nokugcinwa.

Ngamafutshane, ezi mfuno zingasentla kufuneka ziqwalaselwe ngokupheleleyo xa kuhlolwa intsimbi enomfanekiso we-H ukuqinisekisa ukuba umgangatho wayo uyahlangabezana nemigangatho efanelekileyo kunye neemfuno zoku-odola, kunye nokubonelela abasebenzisi ngeemveliso zentsimbi enomfanekiso we-H ezilungileyo.

ISICELO

Imiqadi ye-H section ikwasetyenziswa kakhulu kwishishini lokwakha iinqanawa, apho amandla ayo aphezulu okuthwala umthwalo kunye nokumelana nokugqwala kuzenza zibe zilungele ukwakha izakhiwo ezahlukeneyo zaselwandle. Ngaphezu koko, uyilo lwezakhiwo zanamhlanje ludla ngokusebenzisa imiqadi ye-H section njengezinto zoyilo ezithandekayo, zongeza ukuchukumisa kwemizi-mveliso kwizakhiwo zanamhlanje.

UKUPAKISHA NOKUTHUMELA

Ngaphambi kokuba uthunyelwe, qiniseka ukuba intsimbi enomfanekiso we-H ipakishwe kakuhle kwaye iqinile ukuthintela intshukumo okanye ukungqubana ngexesha lokuthuthwa. Izixhobo zokupakisha ezifanelekileyo kunye nezixhobo, ezifana neebhanti zentsimbi, umthi womqamelo, njl.njl. zingasetyenziswa ukuqinisekisa uzinzo kunye nokhuseleko lwentsimbi enomfanekiso we-H.

Ngokobungakanani, ubunzima kunye nomgama wokuthutha wentsimbi enobume be-H kunye nezinye izinto, khetha indlela yokuthutha efanelekileyo. Kwizithuthi zomgama omfutshane, uthutho lwendlela lunokukhethwa, kusetyenziswa iilori okanye ezinye iindlela zothutho lwendlela; Kwizithuthi zomgama omde, uthutho lukaloliwe lunokufaneleka ngakumbi kuba lunokuthwala inani elikhulu lee-H-beams kwaye luzinzile ngakumbi; Ukuba kufuneka urhwebo lwamazwe ngamazwe okanye uthutho lolwandle olude, uthutho lwamanzi lunokuba lukhetho olufanelekileyo; Kwimeko yeemfuno ezingxamisekileyo okanye zexesha eliphezulu, ungakhetha ukuthutha ngenqwelomoya.

AMANDLA ENKAMPANI

Yenziwe eTshayina, inkonzo yodidi oluphezulu, umgangatho ophezulu, idume kwihlabathi liphela

1. Isiphumo sesikali: Inkampani yethu inekhonkco elikhulu lokubonelela ngempahla kunye nomzi-mveliso omkhulu wentsimbi, ifikelela kwiziphumo zesikali kwezothutho kunye nokuthengwa kwempahla, kwaye iba yinkampani yentsimbi edibanisa imveliso kunye neenkonzo.

2. Ukwahluka kwemveliso: Ukwahluka kwemveliso, nayiphi na intsimbi oyifunayo ingathengwa kuthi, ikakhulu ibandakanya izakhiwo zentsimbi, iireyile zentsimbi, iipali zeshiti zentsimbi, izibiyeli ze-photovoltaic, intsimbi yetshaneli, iikhoyili zesinyithi zesilicon kunye nezinye iimveliso, nto leyo eyenza ukuba iguquguquke ngakumbi Khetha uhlobo lwemveliso oyifunayo ukuhlangabezana neemfuno ezahlukeneyo.

3. Ubonelelo oluzinzileyo: Ukuba nomgca wemveliso ozinzileyo kunye nochungechunge lobonelelo kunokubonelela ngobonelelo oluthembekileyo ngakumbi. Oku kubaluleke kakhulu kubathengi abafuna intsimbi eninzi.

4. Impembelelo yophawu: Banempembelelo ephezulu yophawu kunye nemarike enkulu

5. Inkonzo: Inkampani enkulu yentsimbi edibanisa ukwenziwa ngokwezifiso, uthutho kunye nemveliso

6. Ukhuphiswano lwamaxabiso: ixabiso elifanelekileyo

*Thumela i-imeyile ku[i-imeyile ikhuselwe]ukuze ufumane ikowuteshini yeeprojekthi zakho

FAQ

1. Ndingayifumana njani ikowuteshini kuwe?

Ungasishiyela umyalezo, kwaye siza kuphendula yonke imiyalezo ngexesha elifanelekileyo.

2. Ngaba uza kuzihambisa iimpahla ngexesha elifanelekileyo?

Ewe, sithembisa ukubonelela ngeemveliso ezisemgangathweni ophezulu kunye nokuhanjiswa ngexesha. Ukunyaniseka yimfundiso yenkampani yethu.

3. Ndingafumana iisampulu ngaphambi kokuba ndi-odole?

Ewe, ewe. Ngokwesiqhelo iisampulu zethu zisimahla, singazivelisa ngeesampulu zakho okanye ngemizobo yobugcisa.

4. Ithini imiqathango yakho yokuhlawula?

Ixesha lethu lokuhlawula eliqhelekileyo yidiphozithi ye-30%, kwaye intsalela ihambelana ne-B/L. EXW, FOB, CFR, CIF.

5. Ngaba uyayamkela into yokuhlolwa ngumntu wesithathu?

Ewe siyamkela ngokupheleleyo.

6. Siyithemba njani inkampani yakho?

Siziingcali kwishishini lentsimbi kangangeminyaka emininzi njengomthengisi wegolide, ikomkhulu likwiphondo laseTianjin, samkelekile ukuphanda ngazo zonke iindlela, nangayiphi na indlela.